Anaerobic fermentation and utilization method and equipment for solid waste during bean products processing and application of solid waste

A technology of solid waste and anaerobic fermentation, which is applied in the field of anaerobic fermentation and utilization of solid waste from soybean product processing, can solve the problems of large energy consumption, resources, labor cost, difficulty in comprehensive utilization, and enterprise addition cost, etc. Improve animal feed intake, preserve original nutritional value for a long time, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

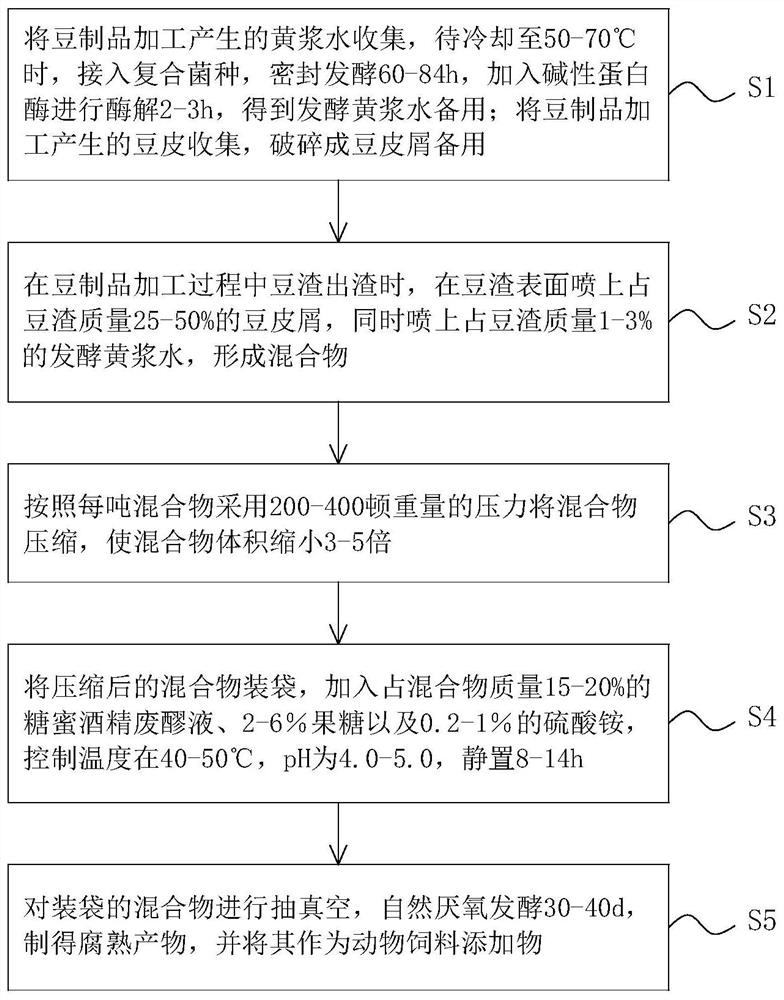

[0027] This embodiment provides a method for anaerobic fermentation and utilization of soybean product processing solid waste, such as figure 1 shown, including the following steps:

[0028] (1) Collect the yellow pulp water produced by the processing of soybean products, and when cooled to 50°C, insert the composite bacteria for sealing and fermentation for 84 hours, add alkaline protease for enzymolysis for 2 hours, and obtain fermented yellow pulp water for later use. The composite bacteria The species include lactic acid bacteria, Bacillus natto, Lactobacillus rhamnosus, Lactobacillus casei and Bifidobacterium, and the mass ratio of each species is Lactic acid bacteria: Bacillus natto: Lactobacillus rhamnosus: Lactobacillus casei: Bifidobacterium =2:1:1.5:1:1; at the same time, collect the bean curds produced during soybean crushing and peeling processing, and break them into bean curds. The moisture of % mass percentage can be directly used as the next step. If the moist...

Embodiment 2

[0034] This embodiment provides a method for anaerobic fermentation and utilization of soybean product processing solid waste, comprising the following steps:

[0035](1) Collect the yellow pulp water produced by the processing of soybean products, and when cooled to 60°C, insert the composite bacteria for sealed fermentation for 60 hours, add alkaline protease for enzymatic hydrolysis for 3 hours, and obtain fermented yellow pulp water for later use. The composite bacteria The species include lactic acid bacteria, Bacillus natto, Lactobacillus rhamnosus, Lactobacillus casei and Bifidobacterium, and the mass ratio of each species is Lactic acid bacteria: Bacillus natto: Lactobacillus rhamnosus: Lactobacillus casei: Bifidobacterium = 2: 1: 1.5: 1: 1; at the same time, collect the bean curds produced during soybean crushing and peeling processing, and crush them into bean curds;

[0036] (2) Spray bean dregs and fermented yellow pulp water on the surface of bean dregs produced i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com