Silicon carbide reinforced silicon-based ceramic core and preparation method thereof

A technology of ceramic cores and silicon carbide, which is applied in the direction of cores, casting molding equipment, casting molds, etc., can solve the problems of short life at high temperature, long core removal cycle, product waste, etc., to improve the efficiency of core removal and improve the efficiency of core removal. Efficiency, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

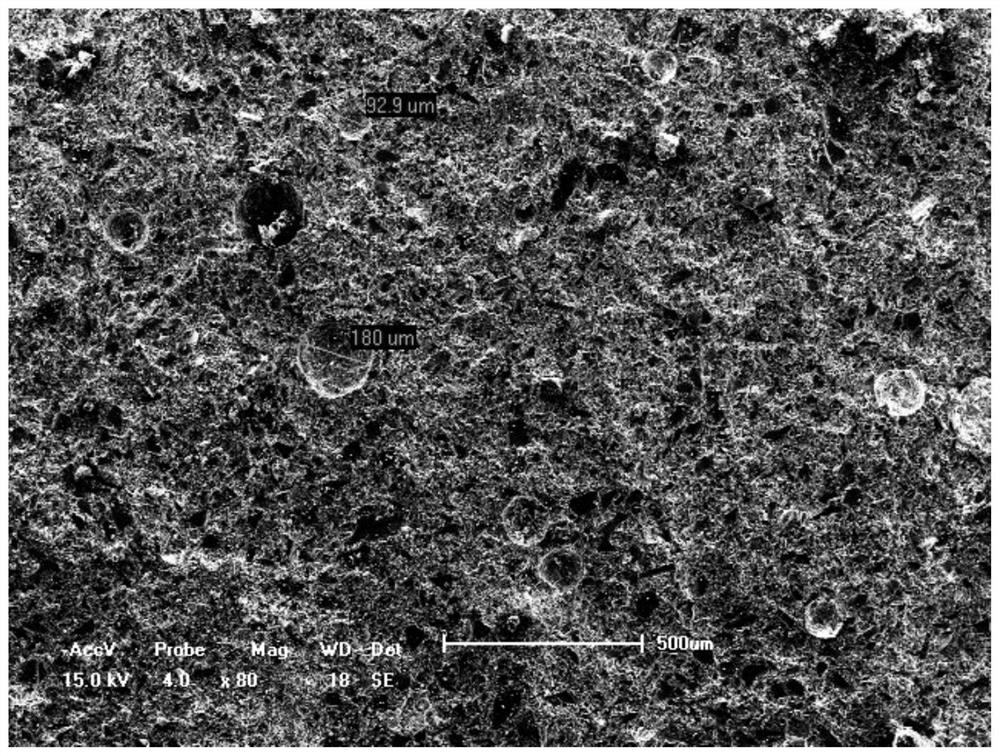

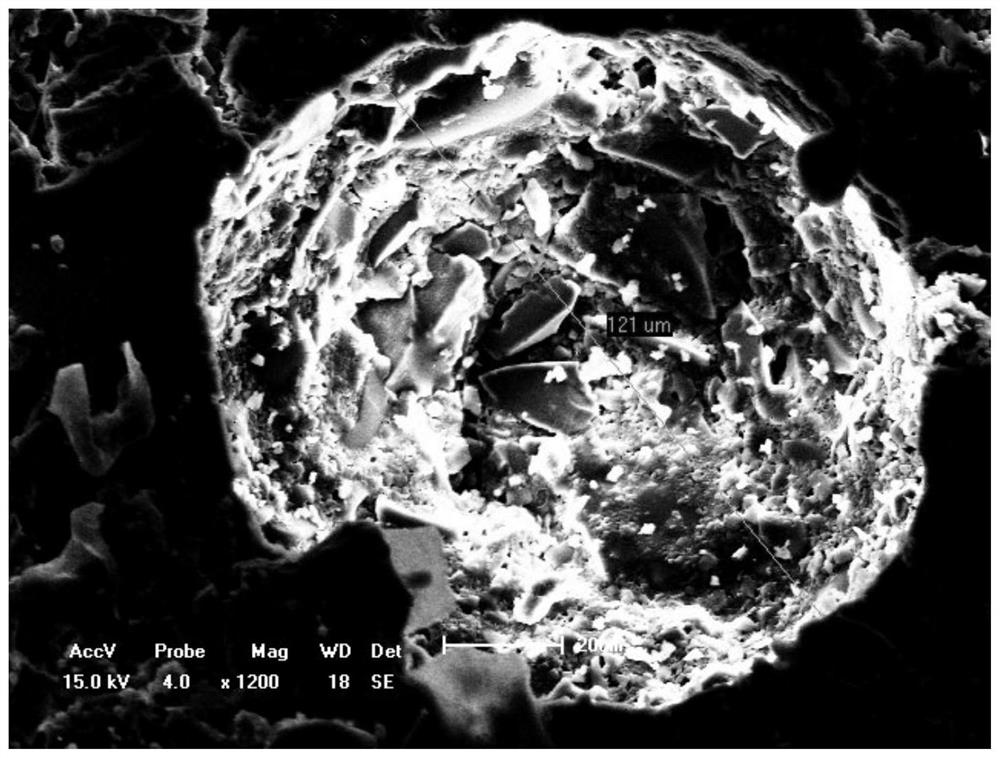

[0061] A silicon carbide reinforced ceramic core, including raw materials: silicon carbide, silicon carbide whiskers, metal powder, silicon oxide and binder; wherein:

[0062] The silicon carbide powder has a purity of more than 99%, a D50 particle size of 325 μm, 8% by mass, 32% by 180 μm, 30% by 40 μm, and 30% by mass of 18 μm;

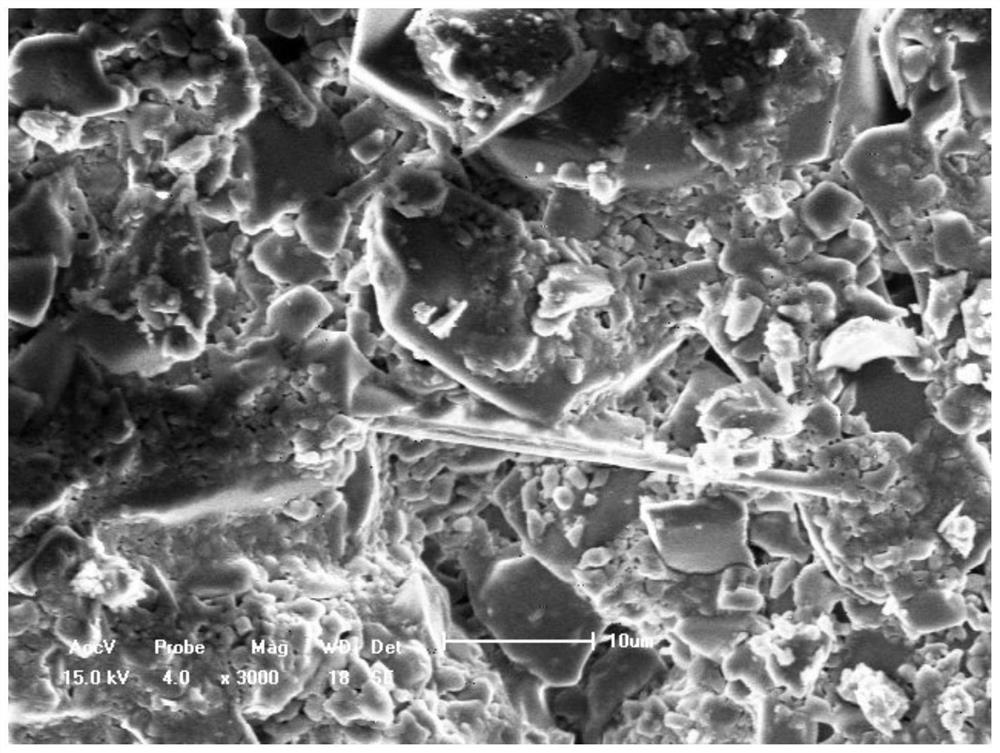

[0063] The silicon carbide whiskers have an average particle size of 100nm and a specific surface area of 30m 2 / g, the added mass is 10% of the silicon carbide powder;

[0064] The particle size of the silicon oxide powder is 70 μm, and the added mass is 32% of the silicon carbide powder;

[0065] The added mass of the metal yttrium powder is 0.7% of the silicon carbide powder;

[0066] The binder is a mixture of liquid paraffin and paraffin at a ratio of 1:1.5, and the added mass is 14% of the mass sum of the above materials;

[0067] The preparation method of the silicon carbide reinforced silicon-based ceramic core comprises the following s...

Embodiment 2

[0077] A silicon carbide reinforced ceramic core, including raw materials: silicon carbide, silicon carbide whiskers, metal powder, silicon oxide and binder;

[0078] The silicon carbide powder has a purity of more than 99%, a D50 particle size of 425 μm, 4% by mass, 30% by 180 μm, 40% by 61 μm, and 26% by mass of 23 μm;

[0079] The silicon carbide whiskers have an average particle size of 100nm and a specific surface area of 30m 2 / g, the added mass is 18% of silicon carbide powder

[0080] The particle size of the silicon oxide powder is 80 μm, and the added mass is 50% of the silicon carbide powder;

[0081] The added mass of the metal yttrium powder is 0.8% of the silicon carbide powder;

[0082] The added mass of the binder is 25% of the total mass of the above materials.

[0083] The preparation method of the silicon carbide reinforced silicon-based ceramic core comprises the following steps:

[0084] (1) prepare materials according to the raw material ratio of si...

Embodiment 3

[0094] A silicon carbide reinforced ceramic core, including raw materials: silicon carbide, silicon carbide whiskers, metal powder, silicon oxide and binder;

[0095] The silicon carbide powder has a purity of more than 99%, a D50 particle size of 550 μm, 5% by mass, 35% by 150 μm, 35% by 70 μm, and 25% by mass of 18 μm;

[0096] The silicon carbide whiskers have an average particle size of 100nm and a specific surface area of 30m 2 / g, the added mass is 12% of the silicon carbide powder;

[0097] The particle size of the silicon oxide powder is 75 μm, and the added mass is 35% of the silicon carbide powder;

[0098] The added mass of the metal yttrium powder is 0.6% of the silicon carbide powder;

[0099] The added mass of the binder is 16% of the sum of the mass of the above materials.

[0100] The preparation method of the silicon carbide reinforced silicon-based ceramic core comprises the following steps:

[0101] (1) prepare materials according to the raw material r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| High temperature flexural strength | aaaaa | aaaaa |

| High temperature flexural strength | aaaaa | aaaaa |

| High temperature flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com