Kaolin for preparing heavy oil catalytic cracking catalyst and preparation method thereof

A technology for cracking catalysts and heavy oil catalysis, which is applied in the fields of physical/chemical process catalysts, chemical instruments and methods, and inorganic chemistry. It can solve the problems of small number of active centers, small specific surface area and pores of kaolin, and limited ability to crack petroleum molecules. Achieve the effects of small radius, accelerated corrosion, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

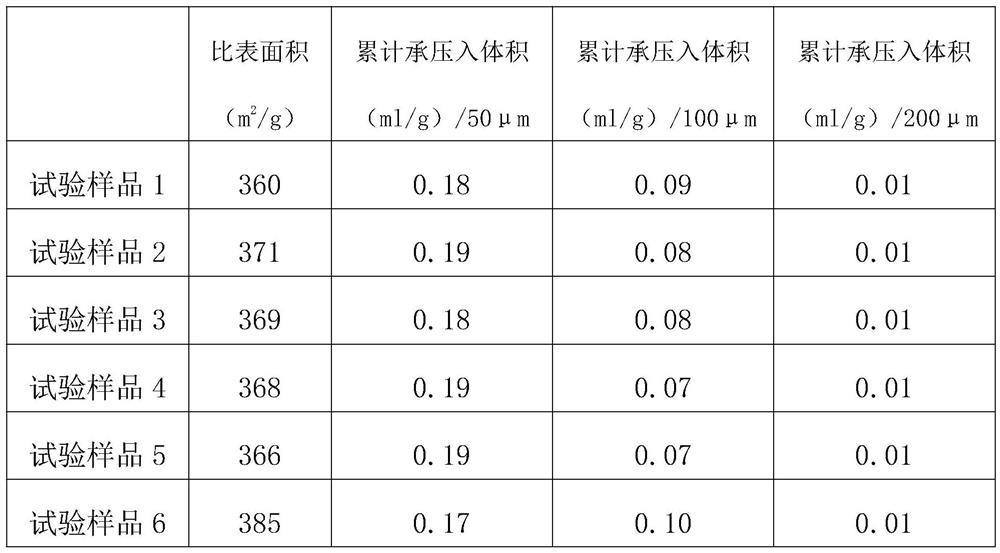

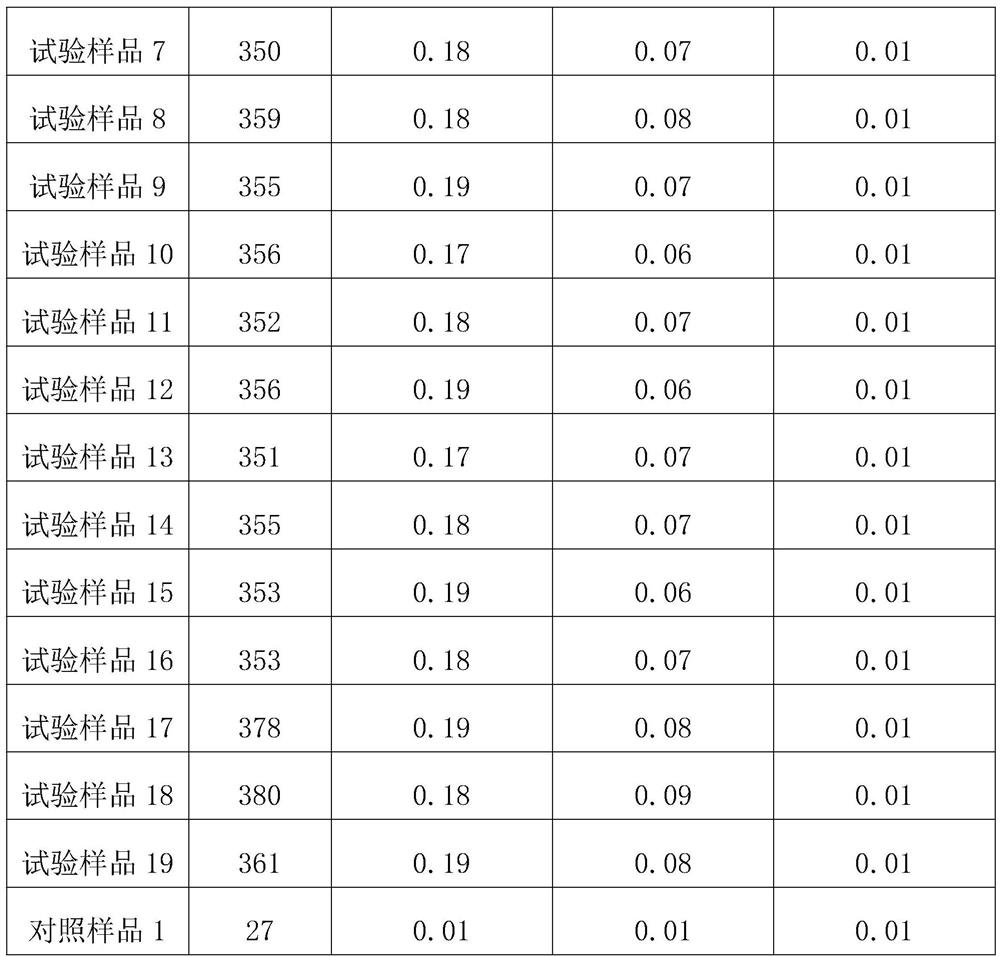

Examples

Embodiment 1

[0044] Embodiment 1: a kind of preparation method for preparing heavy oil catalytic cracking catalyst kaolin, comprises the steps:

[0045] S1. Excavate the loosened kaolin mineral material, and obtain the kaolin base material after preliminary separation of clay and sundries. The kaolin base material is desanded and pulped through a sediment separator to obtain the primary material of kaolin slurry;

[0046] S2. Add 100 parts of kaolin slurry primary material, 0.5 part of a mixed solution of sodium hexametaphosphate solution and sodium silicate sequentially into the slurry storage tank, stir evenly, then add magnesium chloride, and adjust the pH value of the slurry to 6. Among them, hexametaphosphate The ratio of parts by weight of sodium phosphate solution to sodium silicate is 1:2.5;

[0047] S3. When the rotation speed in the slurry storage tank is 100r / min, add 0.65 parts of sodium dithionite to the slurry storage tank, and after reacting for 40 minutes, add 1.2 parts of ...

Embodiment 2

[0050] Embodiment 2: a kind of preparation method for preparing heavy oil catalytic cracking catalyst kaolin, comprises the steps:

[0051] S1. Excavate the loosened kaolin mineral material, and obtain the kaolin base material after preliminary separation of clay and sundries. The kaolin base material is desanded and pulped through a sediment separator to obtain the primary material of kaolin slurry;

[0052]S2. Add 110 parts of kaolin slurry primary material, 0.65 parts of sodium hexametaphosphate solution and sodium silicate mixed solution in turn to the slurry storage tank, stir evenly, then add magnesium chloride, adjust the pH value of the slurry to 6, wherein, hexametaphosphate The ratio of parts by weight of sodium phosphate solution to sodium silicate is 1:3.3;

[0053] S3. When the rotation speed in the slurry storage tank is 100r / min, add 0.8 parts of sodium dithionite to the slurry storage tank, and after reacting for 40 minutes, add 1.3 parts of sulfuric acid to th...

Embodiment 3

[0056] Embodiment 3: a kind of preparation method for preparing heavy oil catalytic cracking catalyst kaolin, comprises the steps:

[0057] S1. Excavate the loosened kaolin mineral material, and obtain the kaolin base material after preliminary separation of clay and sundries. The kaolin base material is desanded and pulped through a sediment separator to obtain the primary material of kaolin slurry;

[0058] S2. Add 120 parts of kaolin slurry primary material, 0.8 part of sodium hexametaphosphate solution and sodium silicate mixed solution in turn to the slurry storage tank, stir evenly, then add magnesium chloride, adjust the pH value of the slurry to 7, wherein, hexametaphosphate The ratio of parts by weight of sodium phosphate solution to sodium silicate is 1:4;

[0059] S3. When the rotation speed in the slurry storage tank is 100r / min, add 0.9 parts of sodium dithionite to the slurry storage tank, and after reacting for 40 minutes, add 1.5 parts of sulfuric acid to the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com