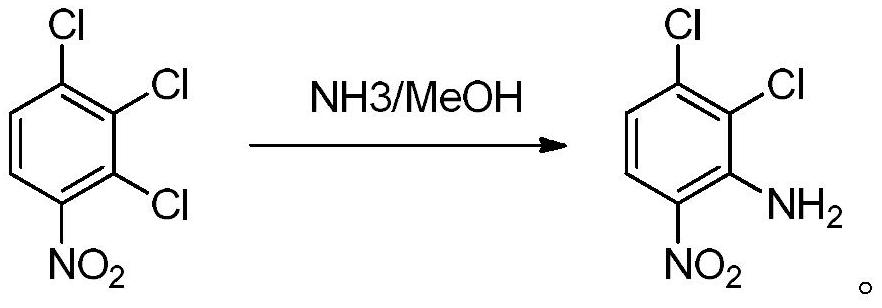

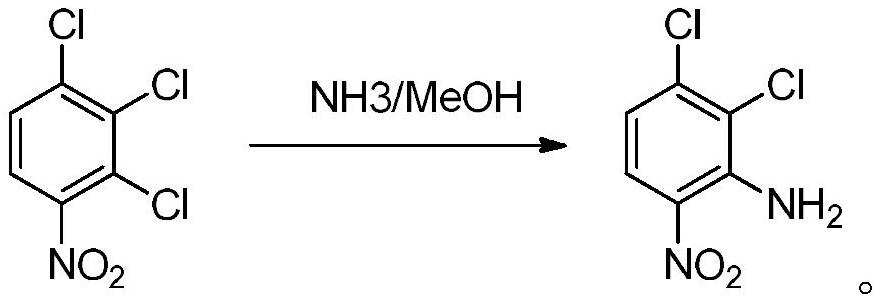

Preparation method of 2,3-dichloro-6-nitroaniline

A technology of nitroaniline and trichloronitrobenzene, which is applied in the field of pesticides, can solve the problems of high reaction temperature in autoclave, cumbersome operation, and low safety, and achieve reduced production energy consumption, good reaction selectivity, and shortened reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Add 240g of water, 240g of 30% ammonia water, 120g of 2,3,4-trichloronitrobenzene, and 6g of p-hydroxybenzenesulfonic acid into the autoclave, start stirring, the reaction temperature is 80°C, keep the temperature for 6 hours, and the pressure is 0.3Mpa , after the reaction, cooled down to room temperature, suction filtered, washed with water, and dried to obtain 108.7g of the target product 2,3-dichloro-6-nitroaniline. The liquid phase purity is 99.5%, and the yield is 99.1%. The filtrate continues to pass through ammonia gas to the reaction concentration and then directly drops into the next batch.

Embodiment 2

[0022] Add 360g of water, 120g of 30% ammonia water, 120g of 2,3,4-trichloronitrobenzene, and 6g of p-hydroxybenzenesulfonic acid into the autoclave, start stirring, the reaction temperature is 80°C, keep the temperature for 6 hours, and the pressure is 0.4Mpa After the reaction, cool down to room temperature, filter with suction, wash with water, and dry to obtain 108.6 g of the target product 2,3-dichloro-6-nitroaniline. The liquid phase purity is 99.3%, and the yield is 99.0%. The filtrate continues to pass through ammonia gas to the reaction concentration and then directly drops into the next batch.

Embodiment 3

[0024] Add 240g of water, 480g of 30% ammonia water, 120g of 2,3,4-trichloronitrobenzene, and 6g of p-hydroxybenzenesulfonic acid into the autoclave, start stirring, the reaction temperature is 80°C, keep the temperature for 6 hours, and the pressure is 0.3Mpa After the reaction, cool down to room temperature, filter with suction, wash with water, and dry to obtain 108.9 g of the target product 2,3-dichloro-6-nitroaniline. The liquid phase purity is 99.6%, and the yield is 99.3%. The filtrate continues to pass through ammonia gas to the reaction concentration and then directly drops into the next batch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com