Novel method for synthesizing ritonavir

A technology of ritonavir and a new method, which is applied in the field of medicinal chemistry, can solve the problems of increasing the difficulty of industrialized large-scale production, harsh reaction conditions, cumbersome operation, etc., and achieve the advantages of large production capacity, production cost and reaction conditions simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

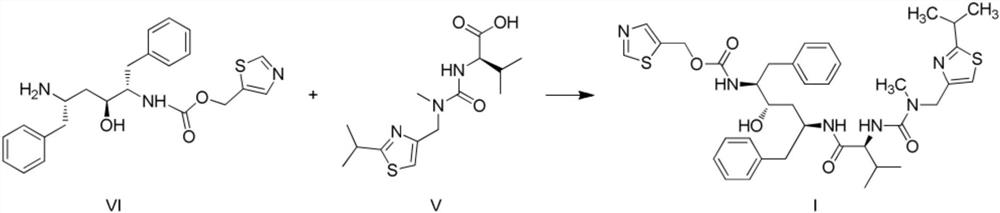

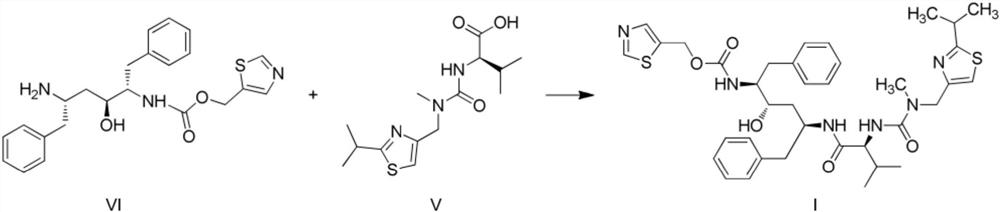

[0025] Embodiment 1 A kind of new method of synthesizing ritonavir

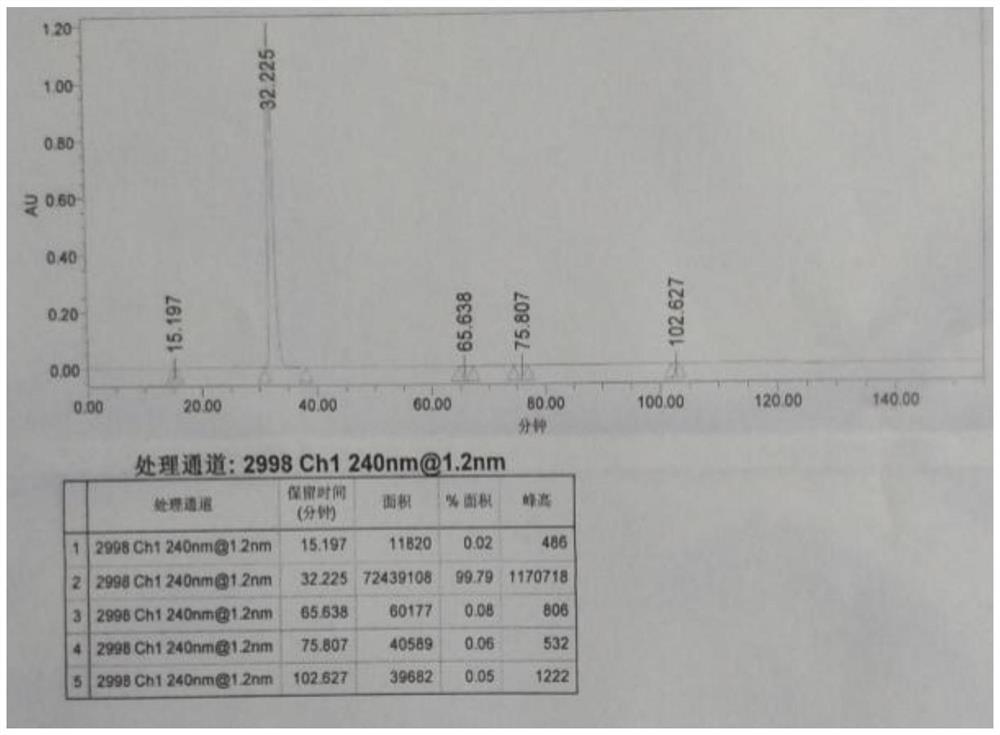

[0026] The reaction kettle R101 is vacuumed, and the nitrogen is evacuated. Under the protection of nitrogen, add 1500kg of dichloromethane and 165kg of intermediate V into the kettle, start stirring and cool down to 5±5°C; add 58.0kg of pivaloyl chloride into the kettle; after adding, Keep the temperature of the reaction kettle R101 at 5±5°C, add 50.0g of triethylamine dropwise into the kettle through the high-level tank V101-I; Add 12.0kg of 4-dimethylaminopyridine (DMAP), stir for 30 minutes, then add the dichloromethane solution of intermediate VI (183.0g dissolved in 500kg); after the addition, the temperature in the kettle is raised to 30±5°C, Stir the reaction for 8-10 hours; take a sample and detect the complete reaction of the intermediate VI by HPLC.

[0027] Post-processing method of ritonavir reaction solution

[0028] Keep the temperature in the reactor at 20±5°C, slowly add 5% sodium hydroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com