Positive electrode material, positive electrode plate and lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in batteries, battery electrodes, secondary batteries, etc., can solve problems such as insufficient compaction density and safety performance, and achieve improved fragility, high compaction density, and good structural stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

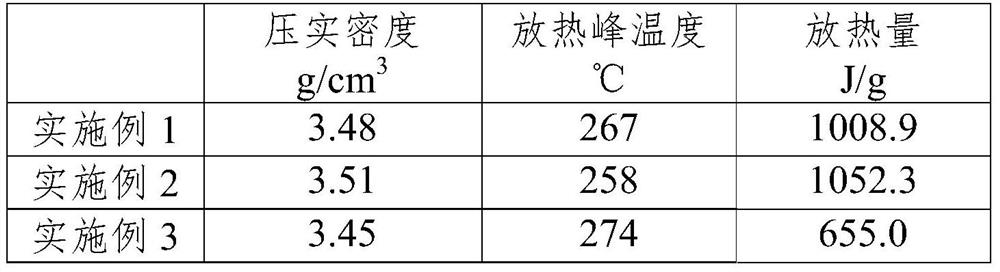

Embodiment 1

[0051] This embodiment is used to illustrate the positive electrode material, positive electrode sheet, lithium ion battery and preparation method thereof disclosed in the present invention, including the following steps:

[0052] (1) Preparation of positive pole piece

[0053] The positive active material is secondary spherical LiNi with D50=10.5 μm 0.8 co 0.1 mn 0.1 o 2 and D50=5.0μm single crystal LiNi 0.83 co 0.12 mn 0.05 o 2 Mix evenly at a ratio of 7:3, and measure the compacted density of the mixed powder to be 3.48g / cm 3 . Mix the powder with conductive carbon black super-P, multi-walled CNT, and binder PVDF according to the mass fraction of 96.5:1.0:0.8:1.7, add an appropriate amount of N-methylpyrrolidone (NMP), and disperse it in a high-speed disperser until the viscosity is high. 3000-6000mPa·S to obtain positive electrode slurry. The above positive electrode slurry was evenly coated on an aluminum foil current collector with a thickness of 14 μm, and the...

Embodiment 2

[0059] This embodiment is used to illustrate the positive electrode material, positive electrode sheet, lithium ion battery and preparation method thereof disclosed in the present invention, including most of the operating steps in Example 1, the difference being:

[0060] In the preparation of the positive pole piece:

[0061] The positive active material is secondary spherical LiNi with D50=11.3μm 0.83 co 0.12 mn 0.05 o 2 and D50=4.8μm single crystal LiNi 0.83 co 0.12 mn 0.05 o 2 Mix evenly at a ratio of 8:2, and measure the compacted density of the mixed powder to be 3.51g / cm 3 .

Embodiment 3

[0063] This embodiment is used to illustrate the positive electrode material, positive electrode sheet, lithium ion battery and preparation method thereof disclosed in the present invention, including most of the operating steps in Example 1, the difference being:

[0064] In the preparation of the positive pole piece:

[0065] The positive active material is secondary spherical LiNi with D50=9.8μm 0.6 co 0.2 mn 0.2 o 2 and D50=6.0μm single crystal LiNi 0.6 co 0.2 mn 0.2 o 2 Mix evenly at a ratio of 9:1, and measure the compacted density of the mixed powder to be 3.45g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com