An all-solid-state iron-air battery

An all-solid-state, solid-state electrolyte technology, applied in battery electrodes, circuits, electrolytes, etc., can solve problems such as battery leakage and negative electrode activity, and achieve the effects of reducing battery leakage behavior, improving performance, and good oxygen ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

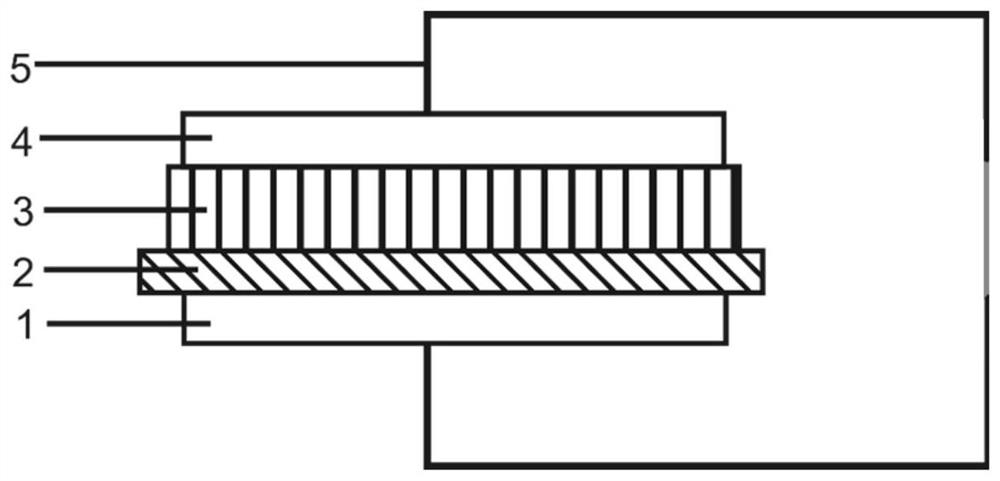

[0027] Negative electrode 1 is potassium-doped iron oxide + YSZ (1:1), separator 2 is ZrO 2 , the solid electrolyte 3 is GDC, the positive electrode 4 is Ag, and the lead 5 is Ag.

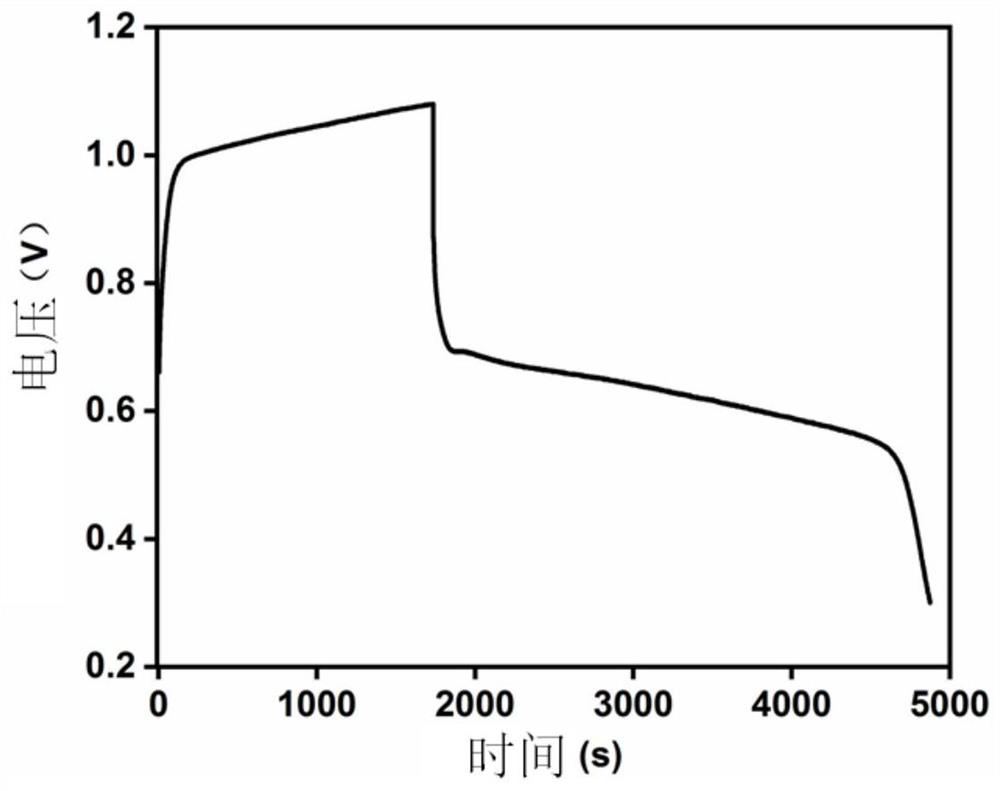

[0028]ZrO was deposited by ion sputtering 2 deposited on the surface of the GDC sheet, and then the negative electrode was coated on ZrO 2 On the other side of the GDC, apply silver paste on the other side of the GDC, and finally lead out the wires with silver wires, and paste the silver wires with silver paste. After the silver paste is solidified, put the battery into an electric furnace at 600°C to keep the temperature constant, and conduct a charge-discharge test. During the test, the working electrodes of the China Landian battery test system are connected to the positive and negative electrodes of the battery respectively, the charging current is set to 10mA, the charging time is 30min, the discharging current is 10mA, and the discharge termination voltage is 0.3V. discharge curve.

[002...

Embodiment 2

[0031] Negative electrode 1 is sodium-doped iron oxide + ZrO 2 (1:1), diaphragm 2 is ZrO 2 , the solid electrolyte 3 is LSGM, the positive electrode 4 is Ag, and the lead 5 is Ag.

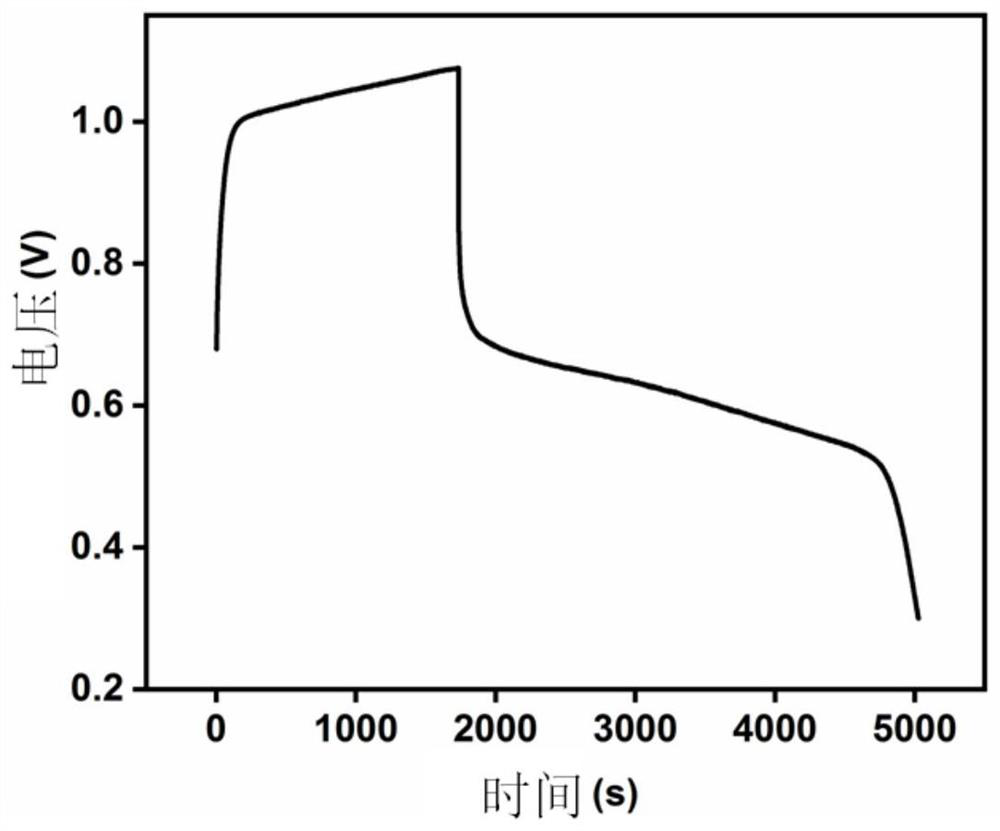

[0032] ZrO was deposited by atomic layer deposition 2 deposited on the surface of the LSGM sheet, and then the negative electrode was coated on ZrO 2 On the other side of the LSGM, apply Ag paste on the other side of the LSGM, and finally lead out the wires with silver wires, and paste the silver wires with silver paste. After the silver paste is solidified, put the battery into an electric furnace at 750°C to keep the temperature constant, and conduct a charge and discharge test. During the test, the working electrodes of the China Landian battery test system are connected to the positive and negative electrodes of the battery respectively, the charging current is set to 10mA, the charging time is 30min, the discharging current is 10mA, and the discharge termination voltage is 0.3V. discharge ...

Embodiment 3

[0035] The negative electrode 1 is lithium-doped iron oxide + YSZ (2:1), and the separator 2 is ZrO 2 , the solid electrolyte 3 is YSZ, the positive electrode 4 is Ag, and the lead 5 is Ag.

[0036] ZrO was deposited by atomic layer deposition 2 Deposit on the surface of YSZ sheet, and then coat the negative electrode on ZrO 2 On the other side of the YSZ, apply Ag paste on the other side of the YSZ, and finally lead out the wires with silver wires, and paste the silver wires with silver paste. After the silver paste is solidified, put the battery into an electric furnace at 850°C to keep the temperature constant, and conduct a charge-discharge test. During the test, the working electrodes of the China Landian battery test system are connected to the positive and negative electrodes of the battery respectively, the charging current is set to 10mA, the charging time is 30min, the discharging current is 10mA, and the discharge termination voltage is 0.3V. discharge curve.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com