An anti-fouling high-concentration organic wastewater transport modified pipe and its preparation method

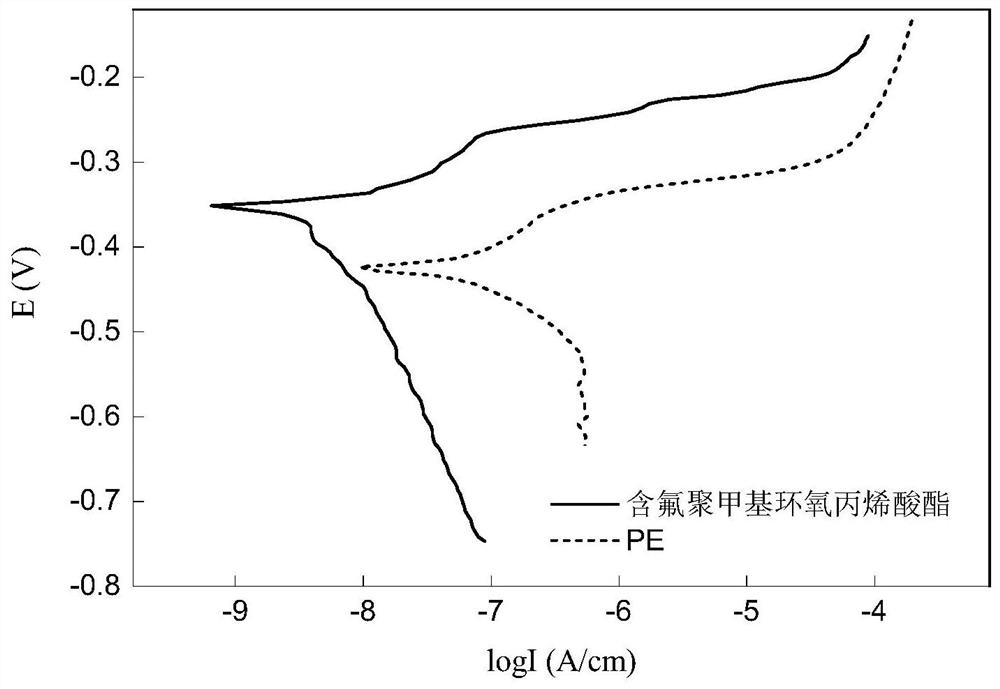

A high-concentration organic wastewater technology, which is applied in the field of high-concentration organic wastewater transport modified pipes and its preparation, can solve problems such as failure to popularize and use, poor anti-scale technology for wastewater transport pipelines, secondary pollution, etc., and achieve Good anti-fouling property, good anti-fouling performance, anti-adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

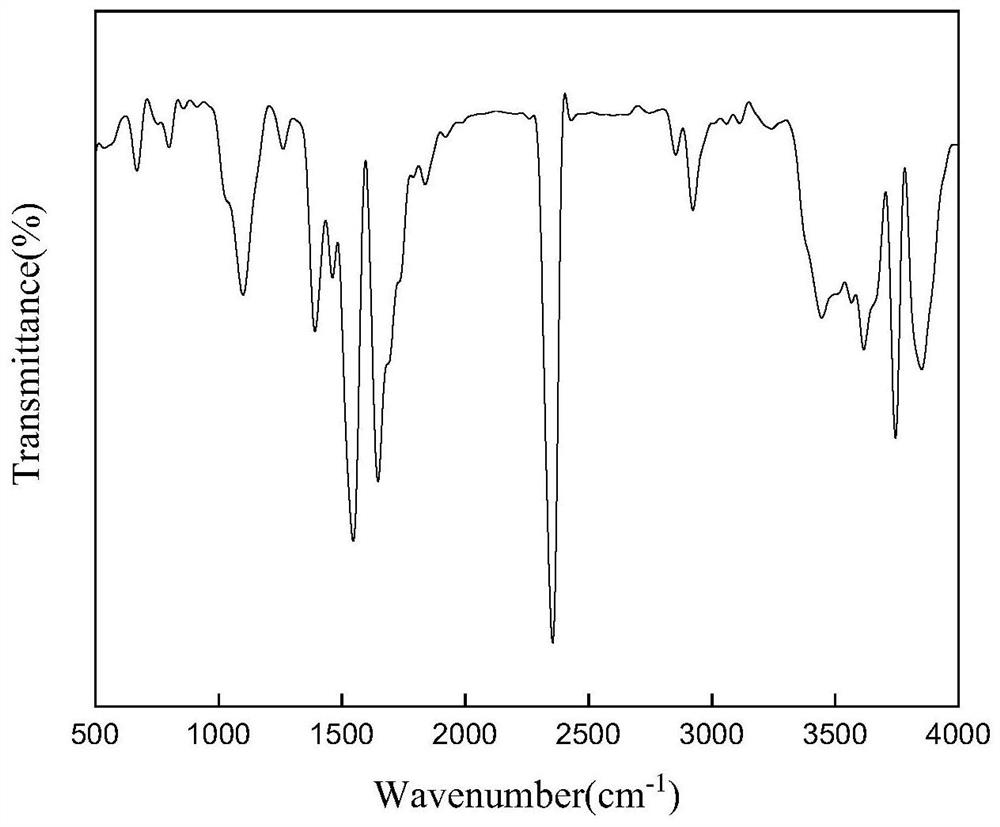

[0038]An anti-fouling high-concentration organic wastewater transport modified pipe, including the following raw materials in parts by weight: 90 parts of high-density polyethylene resin, 19 parts of fluorine-containing polymethyl epoxy acrylate polymer and hydrophobically modified nano-dioxide Silicon 1 part;

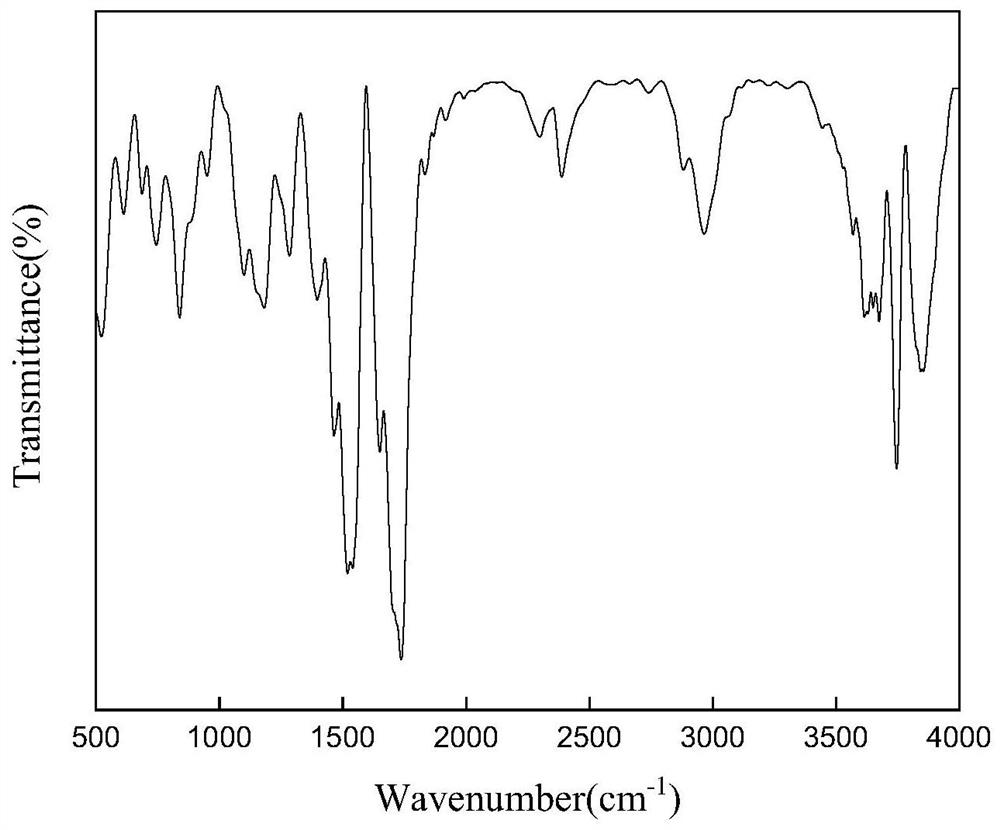

[0039] The above-mentioned fluorine-containing polymethyl epoxy acrylate polymer is prepared by two-step bulk polymerization of hexafluorobutyl methacrylate, butyl methacrylate and glycidyl methacrylate; hexafluorobutyl methacrylate, methyl The mass ratio of butyl acrylate and glycidyl methacrylate is 9:6:3, and the specific preparation process is as follows:

[0040] (1) Mix hexafluorobutyl methacrylate and butyl methacrylate at a mass ratio of 3:2, mix well and add to a reaction kettle with a thermometer to keep the reaction temperature at 75°C; among them, hexafluorobutyl methacrylate The addition of fluorobutyl ester accounts for 1 / 3 of the total amount, and the a...

Embodiment 2

[0050] An anti-fouling high-concentration organic wastewater transport modified pipe, including the following raw materials in parts by weight: 85 parts of high-density polyethylene resin, 12 parts of fluorine-containing polymethyl epoxy acrylate polymer and hydrophobically modified nano-dioxide Silicon 5 parts;

[0051] The above-mentioned fluorine-containing polymethyl epoxy acrylate polymer is prepared by two-step bulk polymerization of hexafluorobutyl methacrylate, butyl methacrylate and glycidyl methacrylate; hexafluorobutyl methacrylate, methyl The mass ratio of butyl acrylate and glycidyl methacrylate is 9:7:2, and the specific preparation process is as follows:

[0052] (1) Mix hexafluorobutyl methacrylate and butyl methacrylate in a mass ratio of 3:2, mix well and add to a reaction kettle with a thermometer to keep the reaction temperature at 77°C; among them, hexafluorobutyl methacrylate The addition of fluorobutyl accounted for 1 / 3 of the total, and the addition of...

Embodiment 3

[0062] An anti-fouling high-concentration organic wastewater transport modified pipe, including the following raw materials in parts by weight: 78 parts of high-density polyethylene resin, 17 parts of fluorine-containing polymethyl epoxy acrylate polymer and hydrophobically modified nano-dioxide Silicon 5 parts;

[0063] The above-mentioned fluorine-containing polymethyl epoxy acrylate polymer is prepared by two-step bulk polymerization of hexafluorobutyl methacrylate, butyl methacrylate and glycidyl methacrylate; hexafluorobutyl methacrylate, methyl The mass ratio of butyl acrylate and glycidyl methacrylate is 10:6:3, and the specific preparation process is as follows:

[0064] (1) Mix hexafluorobutyl methacrylate and butyl methacrylate in a mass ratio of 3:2, mix well and add to a reaction kettle with a thermometer to keep the reaction temperature at 76°C; among them, hexafluorobutyl methacrylate The addition of fluorobutyl accounted for 1 / 3 of the total, and the addition o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com