Antibacterial non-woven material and preparation method thereof

A technology of raw materials and antibacterial agents, which is applied in the field of antibacterial non-woven materials and its preparation, can solve the problems of reduced antibacterial effect and shedding of polymer film-forming agents, so as to increase the overall strength and toughness, enhance uniformity, and reduce interference degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

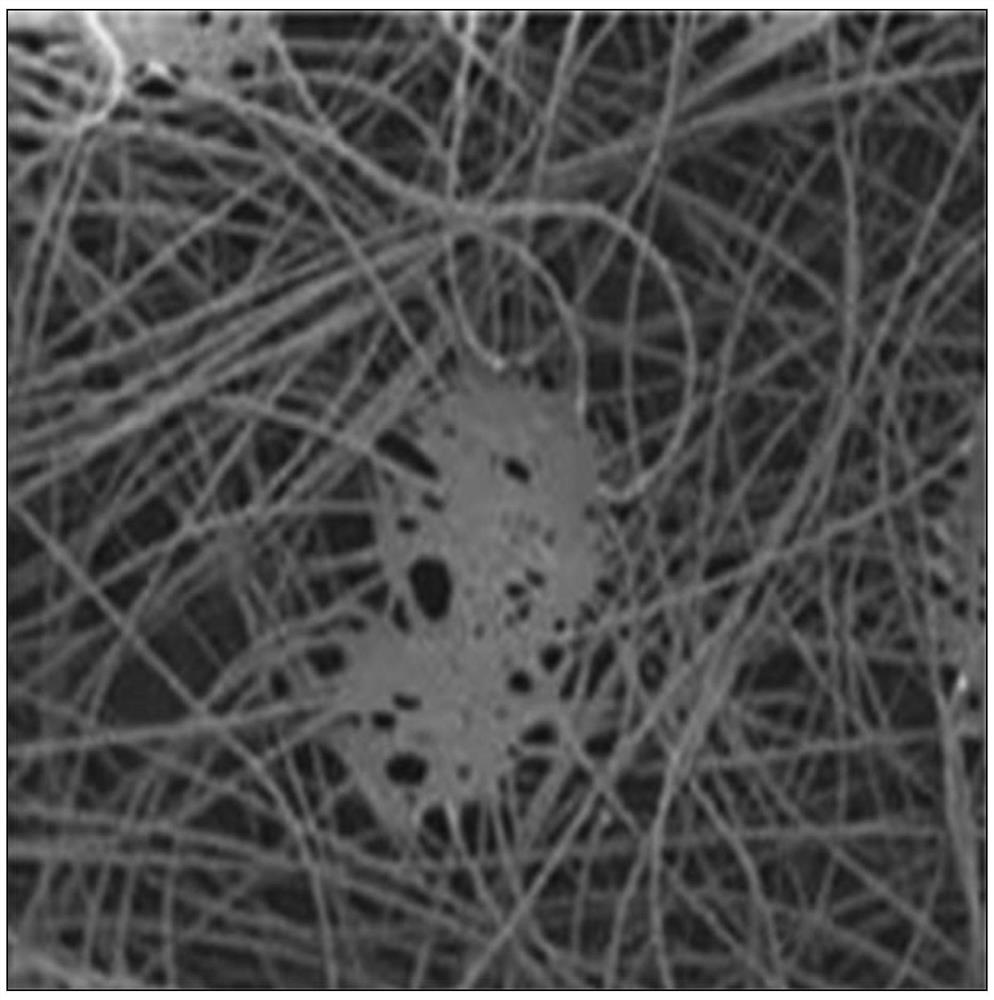

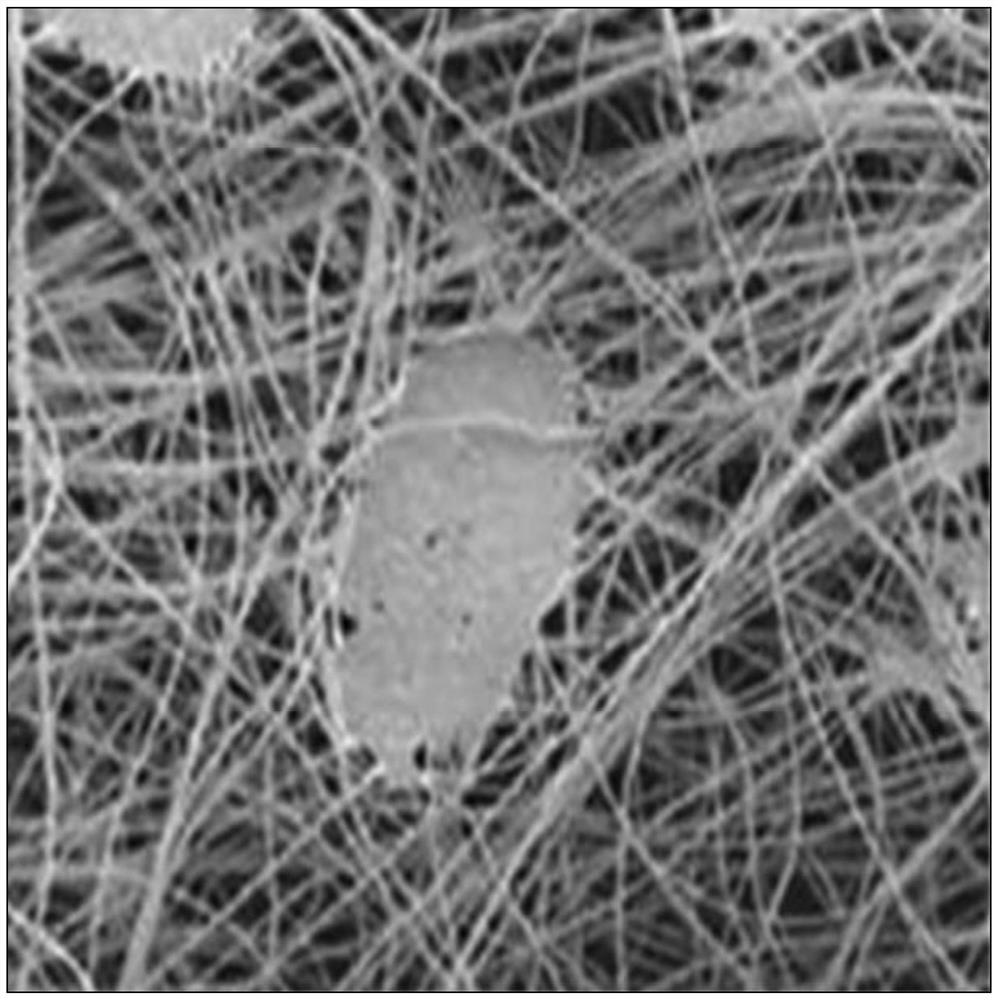

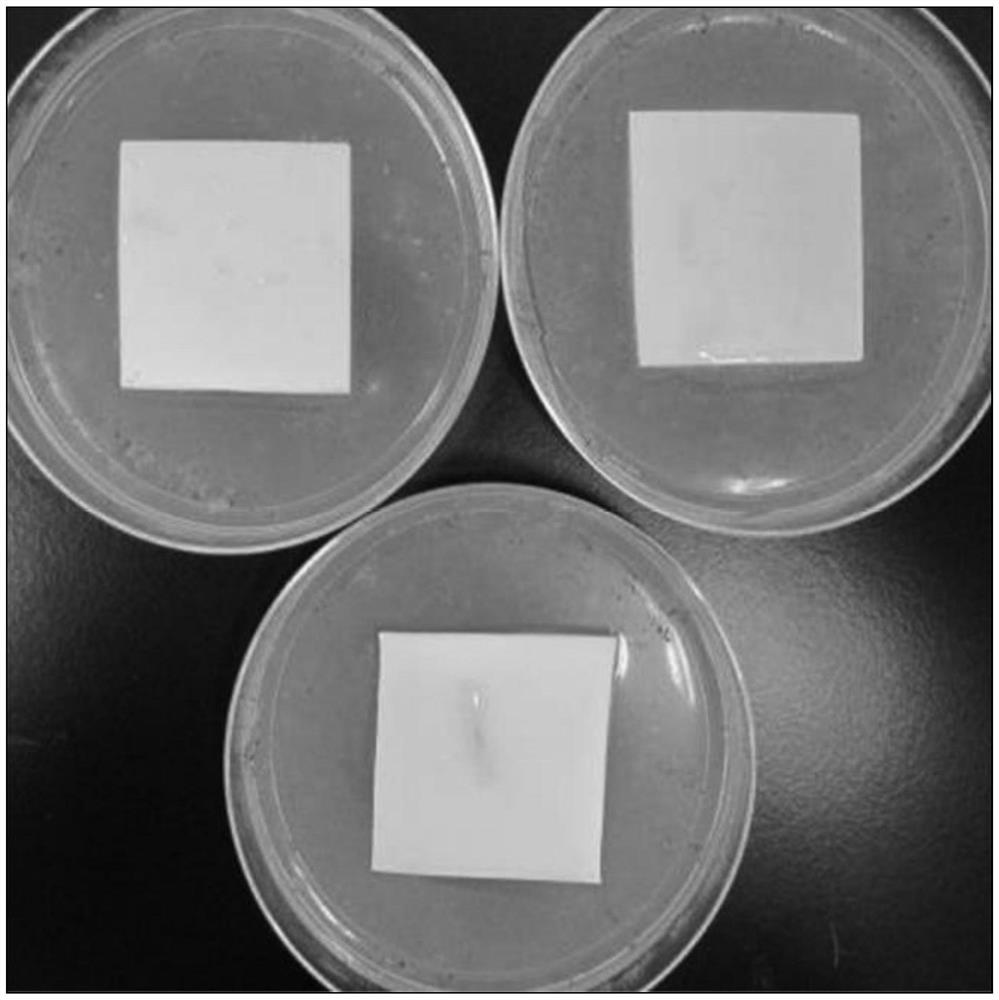

Image

Examples

Embodiment 1

[0051] A kind of antibacterial non-woven material is made of the raw materials of following parts by weight:

[0052] Polypropylene 80 parts

[0053] Initiator A 0.5 part

[0054] Antioxidant 0.1 parts

[0055] 1 part antiseptic

[0056] Electret masterbatch 3 parts

[0057] Nucleating agent 0.1 parts

[0058] LMPP 10 parts

[0059] Wherein, polypropylene is a commercially available product.

[0060] Initiator A is a commercially available product. In addition, other initiators capable of initiating free radicals can be used.

[0061] Antioxidant is a commercially available product, here is phosphite antioxidant, Weston 618.

[0062] The antibacterial agent is a commercially available product, here is a silver ion antibacterial agent, Zeomic DAW502.

[0063] The electret masterbatch is a commercially available product.

[0064] The nucleating agent is a commercially available product, here is an organophosphate nucleating agent, NA-21.

[0065] LMPP is a commercially...

Embodiment 2

[0077] The difference between this embodiment and Embodiment 1 is that a kind of antibacterial non-woven material is made of the following raw materials in parts by weight:

[0078] Polypropylene 100 parts

[0079] Initiator A 1 part

[0080] Antioxidant 1 part

[0081] Antibacterial agent 2 parts

[0082] Electret masterbatch 6 parts

[0083] Nucleating agent 1 part

[0084] LMPP 15 parts

[0085] The antioxidant is a commercially available product, here is a phosphite antioxidant, irgafos 168.

[0086] The antibacterial agent is a commercially available product, here is a zinc ion antibacterial agent, Japan Jifu ZPT.

[0087] The nucleating agent is a commercially available product, here is a rosin salt nucleating agent, Zhejiang Vian Plastics, a rosin type polyolefin transparent nucleating agent.

[0088] Using the raw materials in this example in parts by weight, the antibacterial nonwoven material was prepared by using the preparation method in Example 1.

Embodiment 3

[0090] The difference between this embodiment and Embodiment 1 is that a kind of antibacterial non-woven material is made of the following raw materials in parts by weight:

[0091] Polypropylene 120 parts

[0092] Initiator A 2 parts

[0093] Antioxidant 2 parts

[0094] Antibacterial agent 3 parts

[0095] Electret masterbatch 10 parts

[0096] Nucleating agent 2 parts

[0097] LMPP 20 copies

[0098] The antibacterial agent is a commercially available product, and here is a zinc ion antibacterial agent, U.S. Austrian Qi, Zinc Omadie Powder.

[0099] Using the raw materials in this example in parts by weight, the antibacterial nonwoven material was prepared by using the preparation method in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com