A kind of table edge surround material and preparation method thereof

A technology of raw materials and materials, applied in the field of composite material preparation, to achieve the effects of strength reinforcement, rich sources of raw materials, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

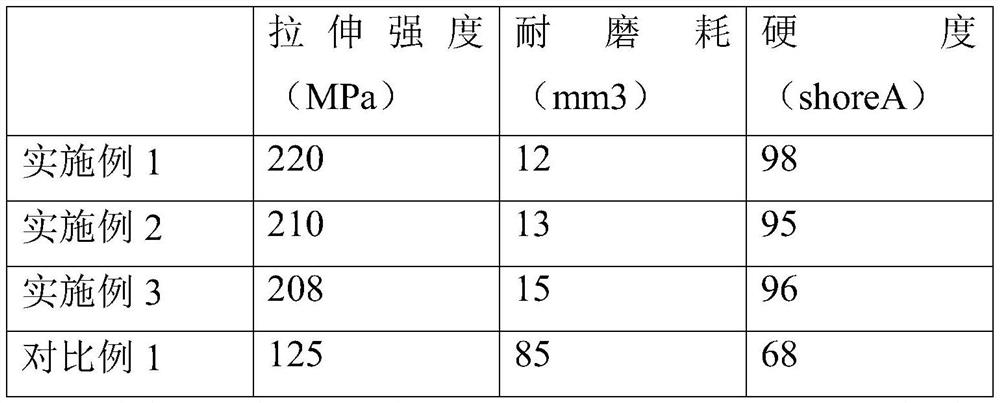

Examples

preparation example Construction

[0025]The present invention also proposes a preparation method of the table edge surrounding material, comprising the following steps:

[0026] S1. Mix thermoplastic polyurethane elastomer and polyvinyl chloride evenly, heat up to 140-160°C, keep warm for 20-30min, then add sodium potassium silicate, blue alum, short polyester fiber, long glass fiber, and nano-calcium carbonate and mix evenly , stirred at a speed of 1500-2500r / min for 20-40min, cooled to room temperature to obtain the base material;

[0027] S2. Heat up polytetrafluoroethylene to 150-160°C, stir at 450-650r / min for 20-40min, then cool down to 80-90°C, keep warm for 10-30min, then add material a, wear-resistant enhancer, Mix the chain extender, modified reinforcing agent A and modified reinforcing agent B evenly, raise the temperature to 110-130°C, keep it warm for 10-20min, and stir at 1050-1350r / min for 1-2h to obtain the tableside surround material.

Embodiment 1

[0029] A kind of table edge surround material, its raw material comprises by weight: 100 parts of thermoplastic polyurethane elastomer, 45 parts of polyvinyl chloride, 40 parts of polytetrafluoroethylene, 10 parts of potassium sodium silicate, 6 parts of blue alum, polyester staple fiber 6 parts, 6 parts of long glass fiber, 5 parts of nano-calcium carbonate, 15 parts of wear-resistant enhancer, 6 parts of chain extender, 20 parts of modified reinforcing agent A, and 24 parts of modified reinforcing agent B.

[0030] The chain extender is 1,4-butanediol.

[0031] The modified reinforcing agent A is prepared according to the following process: 60 parts by weight of 4,4'-diaminodiphenylsulfone and 25 parts of butanediol are mixed in a container filled with nitrogen, and the temperature is raised to 50 while stirring. ℃, after the system becomes transparent, cool down to room temperature, add 10 parts of trimellitic anhydride and mix evenly, then raise the temperature to 160 ℃, k...

Embodiment 2

[0038] A kind of table side surrounding material, its raw material comprises by weight: 80 parts of thermoplastic polyurethane elastomers, 50 parts of polyvinyl chloride, 20 parts of polytetrafluoroethylene, 15 parts of potassium sodium silicate, 4 parts of blue alum, polyester staple fiber 9 parts, 4 parts of long glass fiber, 8 parts of nano-calcium carbonate, 10 parts of wear-resistant enhancer, 8 parts of chain extender, 15 parts of modified reinforcing agent A, and 32 parts of modified reinforcing agent B.

[0039] The chain extender is hydroquinone-bis(β-hydroxyethyl)ether.

[0040] The modified reinforcing agent A is prepared according to the following process: 40 parts by weight of 4,4'-diaminodiphenylsulfone and 30 parts of butanediol are mixed in a container filled with nitrogen, and the temperature is raised to 40 while stirring. ℃, after the system becomes transparent, lower it to room temperature, add 15 parts of trimellitic anhydride and mix evenly, then raise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com