Soil heavy metal passivator as well as preparation method and application thereof

A heavy metal passivator and soil technology, applied in the field of soil remediation, can solve the problems of large amount of passivator application, soil structure damage, complex components, etc., achieve excellent heavy metal activity, reduce heavy metal absorption, and not damage the soil structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

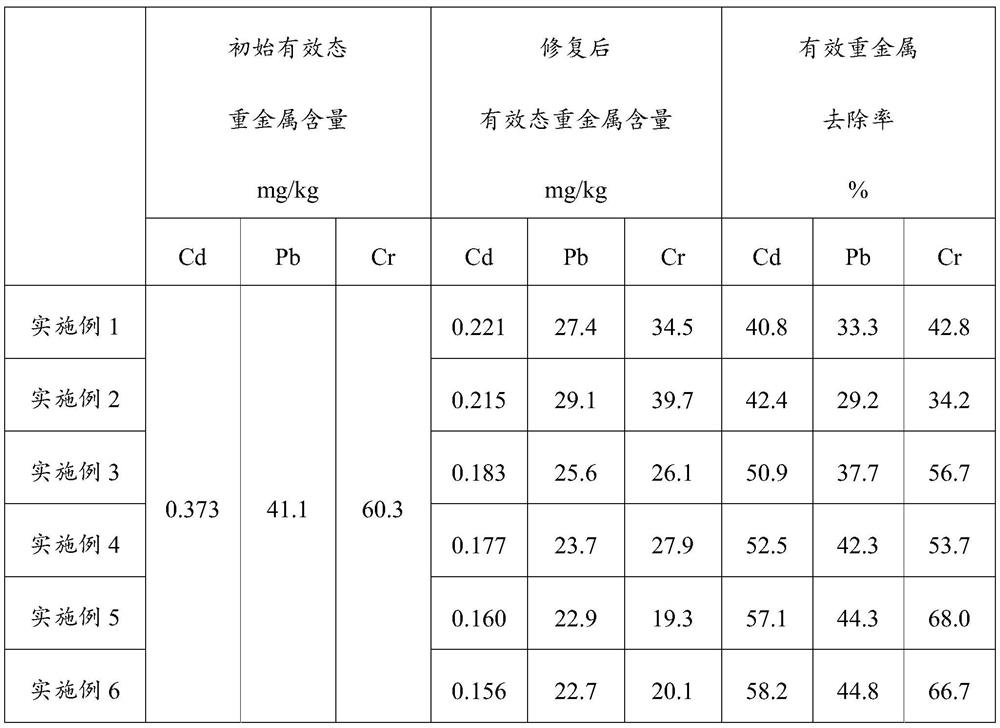

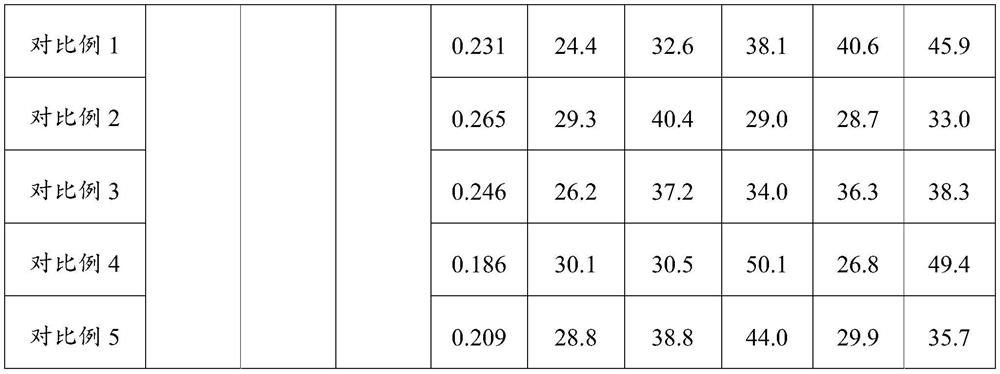

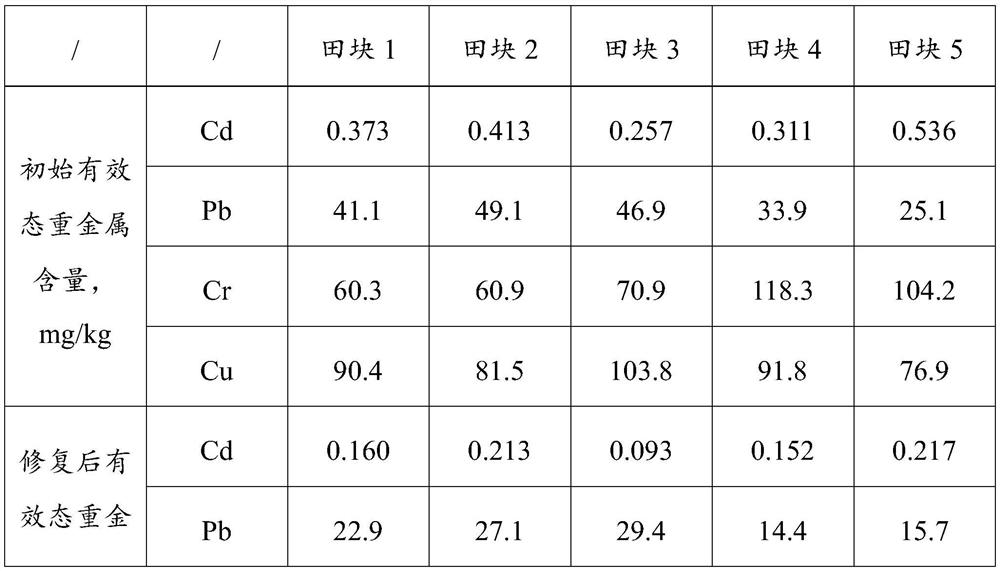

Examples

Embodiment 1

[0038] Present embodiment provides a kind of soil heavy metal deactivator, and its composition is:

[0039] 75kg of carbonized bone powder; 30kg of metal salt antagonists, including 20kg of manganese chloride and 10kg of ferrous sulfate; 50kg of solid alkali, including 25kg of slaked lime and 25kg of plant ash.

[0040] The preparation method of described soil heavy metal deactivator is:

[0041] Commercially available bone meal (bone meal for feed that meets the requirements of the "GB / T 20193-2006 Feed Bone Meal and Meat and Bone Meal" standard) was subjected to low-temperature carbonization under nitrogen conditions. The carbonization temperature was 600°C, the carbonization time was 2 hours, and the nitrogen flow rate was 3.0 L / min, obtain carbonized bone meal;

[0042] Dissolve the metal antagonist in 90kg of water, then mix evenly with carbonized bone meal, dry at 90°C for 6 hours, and then mix evenly with solid base to obtain a soil heavy metal passivator.

Embodiment 2

[0044] Present embodiment provides a kind of soil heavy metal deactivator, and its composition is:

[0045] 33kg of carbonized bone powder; 7kg of metal salt antagonists, including 3kg of zinc sulfate and 4kg of magnesium chloride; 10kg of solid alkali, including 5kg of slaked lime and 5kg of limestone.

[0046] The preparation method of described soil heavy metal deactivator is:

[0047] Carry out low-temperature carbonization of commercially available bone meal (bone meal for feed that conforms to the standard requirements of "GB / T 20193-2006 Feed Bone Meal and Meat and Bone Meal") under nitrogen. The carbonization temperature is 300°C, the carbonization time is 5 hours, and the nitrogen flow rate is 0.5 L / min, obtain carbonized bone meal;

[0048] The metal antagonist was dissolved in 7kg of water, then mixed evenly with carbonized bone meal, dried at 70°C for 6 hours, and then mixed evenly with solid base to obtain a soil heavy metal passivator.

Embodiment 3

[0050] Present embodiment provides a kind of soil heavy metal deactivator, and its composition is:

[0051] 60kg of carbonized bone powder; 23kg of metal salt antagonists, including 10kg of manganese sulfate, 8kg of ferric chloride, and 5kg of calcium chloride; 40kg of solid alkali, including 40kg of quicklime.

[0052] The preparation method of described soil heavy metal deactivator is:

[0053] Commercially available bone meal (bone meal for feed that meets the requirements of the "GB / T 20193-2006 Feed Bone Meal and Meat and Bone Meal" standard) was subjected to low-temperature carbonization under nitrogen conditions. The carbonization temperature was 600°C, the carbonization time was 2 hours, and the nitrogen flow rate was 3.0 L / min, obtain carbonized bone meal;

[0054] Dissolve the metal antagonist in 46kg of water, then mix evenly with the carbonized bone powder obtained by the above method, dry at 80°C for 6 hours, and then mix evenly with solid alkali to obtain a soil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com