Method for producing edible fungus beverage based on subcritical hydrothermal treatment

A subcritical water and edible fungus technology, applied in the direction of heat treatment of food, medical raw materials derived from fungi, sugary food ingredients, etc. The effect of shortening the production process, retaining flavor and nutrition, and improving the dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for producing edible fungus beverage based on subcritical hydrothermal treatment, comprising the following steps:

[0056] S1. Wash the edible fungus and mix with water to soak for 20 minutes to obtain a mixed solution;

[0057] Wherein, the edible fungus is obtained by mixing at least one of white fungus, black fungus, Hericium erinaceus, golden ear, Pleurotus chinensis, Armillaria armillaria and plastic spoons in equal parts; the mass ratio of edible fungus to water is 1:50, The water is cold water or water at 50-60°C;

[0058] S2. Get mixed solution and edible acetic acid to mix, at rotating speed be 6000rpm / min, under the condition that time is 2min, carry out positive and negative two-way cutting to it, obtain bacterial suspension; Wherein, the volume ratio of edible acetic acid and bacterial suspension is 6: 100;

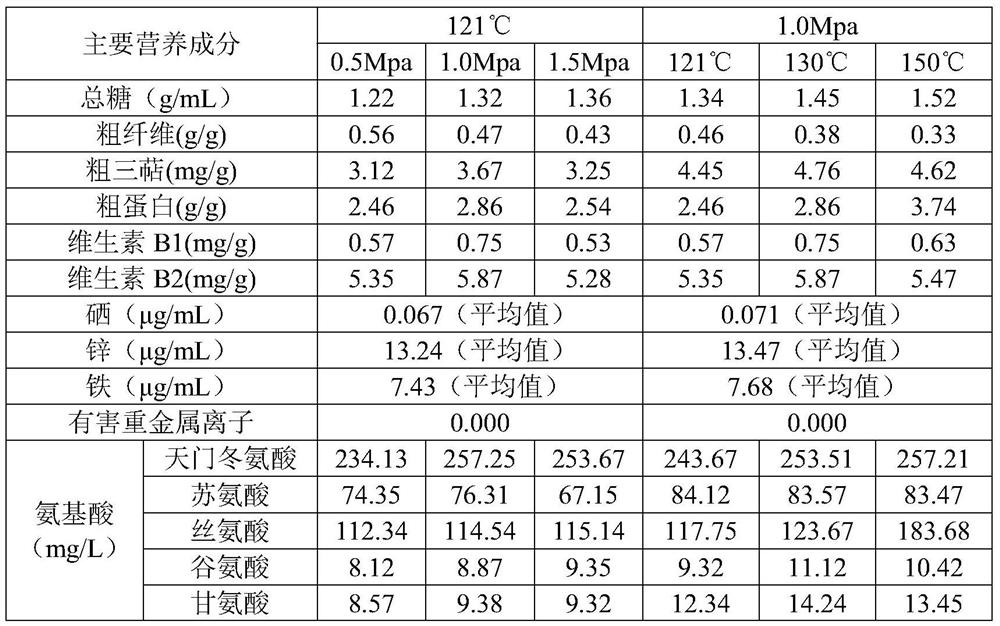

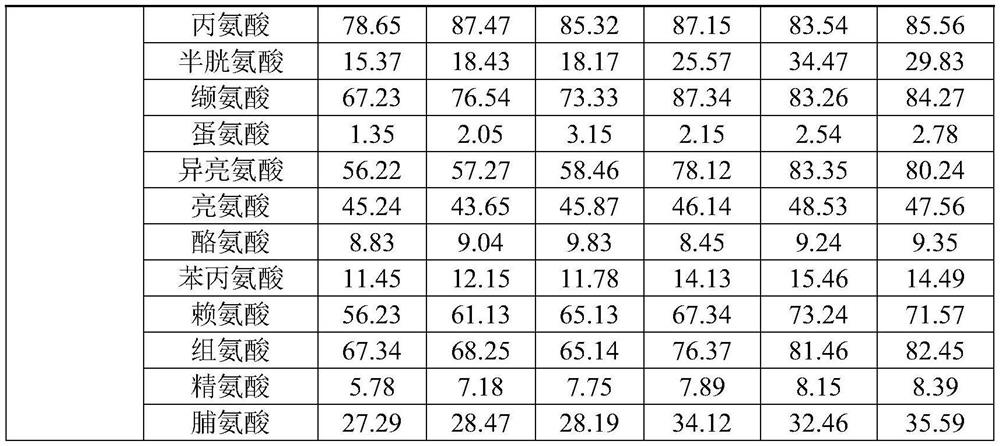

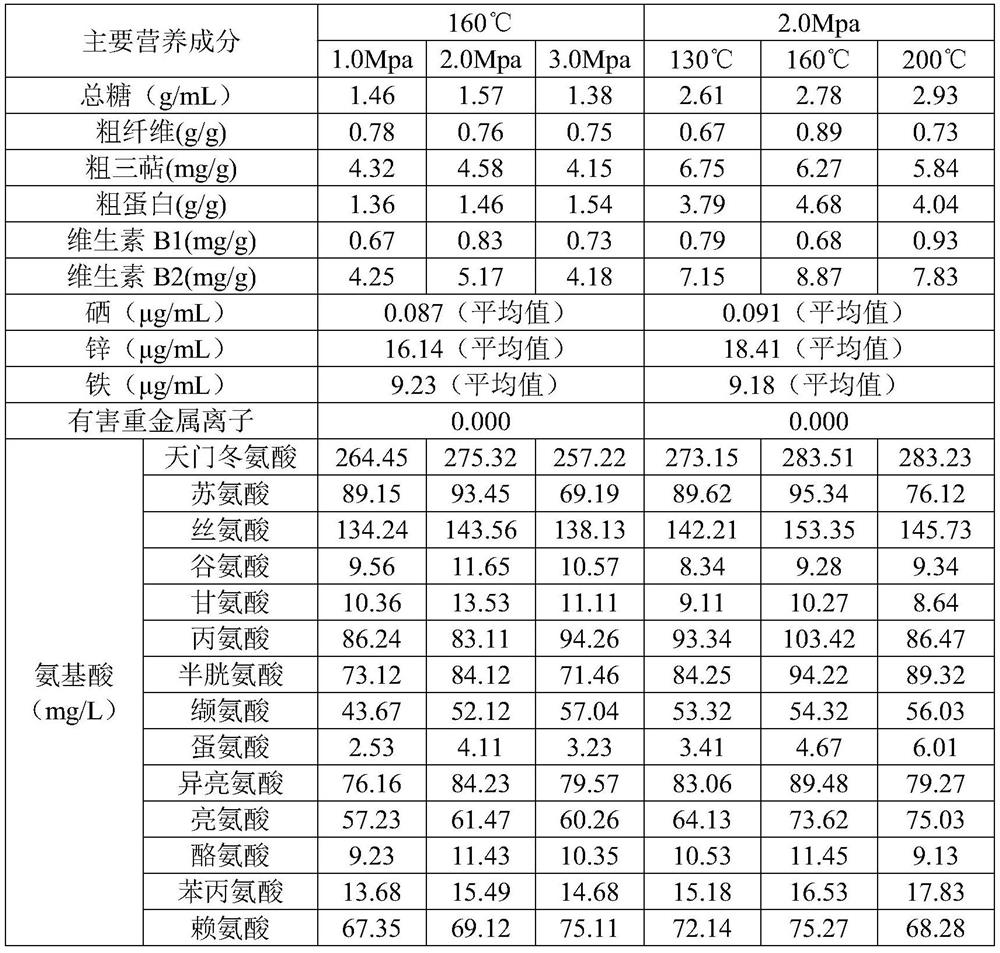

[0059] S3. Using the bacterial suspension, carry out subcritical hydrothermal treatment under 6 kinds of conditions respectively, and obtain...

Embodiment 2

[0075] A method for producing edible fungus beverage based on subcritical hydrothermal treatment, comprising the following steps:

[0076] S1. Wash the edible fungus and mix with water to soak for 40 minutes to obtain a mixed solution;

[0077] Wherein, the edible fungi are obtained by mixing at least one of shiitake mushrooms, Coprinus comatus, mushrooms, morels, pine mushrooms, Agaricus bisporus and Pleurotus auricosa in equal parts; the mass ratio of edible fungi to water is 1:30, and the water It is cold water or water at 50-60°C;

[0078] S2. Get the mixed solution and mix with edible acetic acid, and at a rotating speed of 10000rpm / min, under the condition of 5min, it is carried out forward and reverse bidirectional cutting to obtain bacterial suspension; wherein, the volume ratio of edible acetic acid and bacterial suspension is 8: 100;

[0079] S3. Using the bacterial suspension, carry out subcritical hydrothermal treatment under 6 kinds of conditions respectively, a...

Embodiment 3

[0097] A method for producing edible fungus beverage based on subcritical hydrothermal treatment, comprising the following steps:

[0098] S1. Wash the edible fungus and mix with water to soak for 30 minutes to obtain a mixed solution;

[0099] Wherein, the edible fungus is obtained by mixing at least one of Ganoderma lucidum, Poria cocos, Pleurotus eryngii, Xanthomonas chrysanthemum, Pine mushroom, Boletus and Gallinaceae; the mass ratio of edible fungus to water is 1:30 , the water is cold water or water at 50-60°C;

[0100] S2. Get mixed solution and edible acetic acid to mix, be 10000rpm / min at rotating speed, under the condition that time is 3min, carry out positive and negative two-way cutting to it, obtain bacterial suspension; Wherein, the volume ratio of edible acetic acid and bacterial suspension is 7: 100;

[0101] S3. Using the bacterial suspension, carry out subcritical hydrothermal treatment under 6 kinds of conditions respectively, and obtain reaction liquids ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com