High-concentration bioconcentration reactor and method for treating handmade rice wine wastewater

A wastewater treatment and bio-enrichment technology, which is applied in biological water/sewage treatment, food industry wastewater treatment, sustainable biological treatment, etc., can solve problems such as difficult to achieve coordinated pollutant standards, and reduce engineering investment and operating costs. The effect of improving utilization and avoiding competitive consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

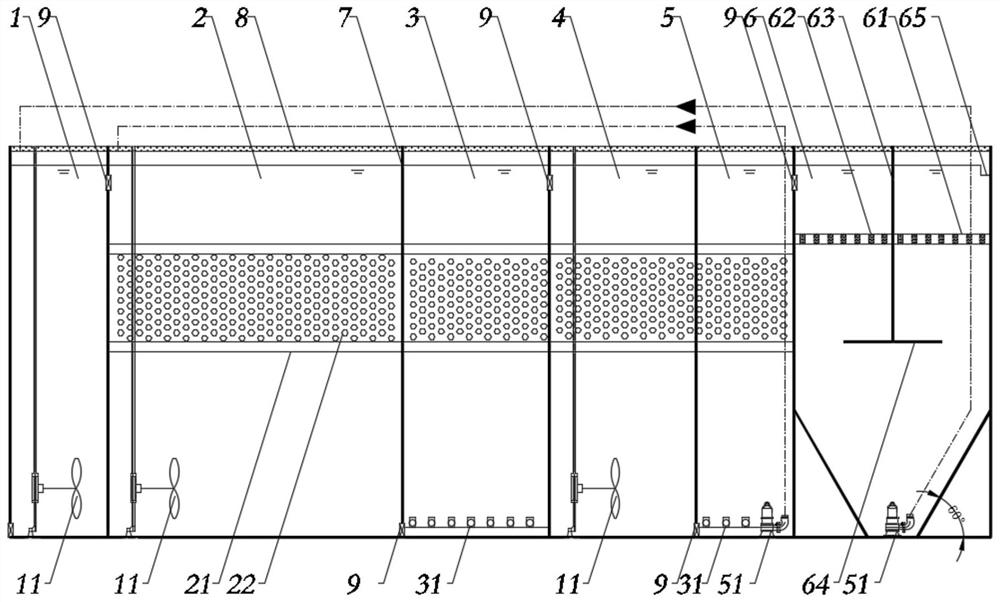

[0038] refer to figure 1 As shown, this embodiment provides a high-concentration bio-concentration reactor for the treatment of handmade rice wine wastewater. The main body of the bio-concentration reactor is a box body, and the box body includes a pre-aeration zone 1, a first-level hypoxia Zone 2, primary aerobic zone 3, secondary anoxic zone 4, secondary aerobic zone 5, enrichment and concentration zone 6, each zone is separated by a separator 7, and the flow of treated wastewater is realized through the water hole, The top of the box is covered with a grid cover 8 made of glass fiber reinforced plastic.

[0039] Wherein, the first-level anoxic zone, the first-level aerobic zone, the second-level anoxic zone, and the second-level aerobic zone are filled with microbial carrier fillers 22 in the middle of the height of the box. A submersible mixer 11 is installed at the bottom of the front deoxygenation zone, the primary hypoxia zone and the secondary hypoxia zone. An aerati...

Embodiment 2

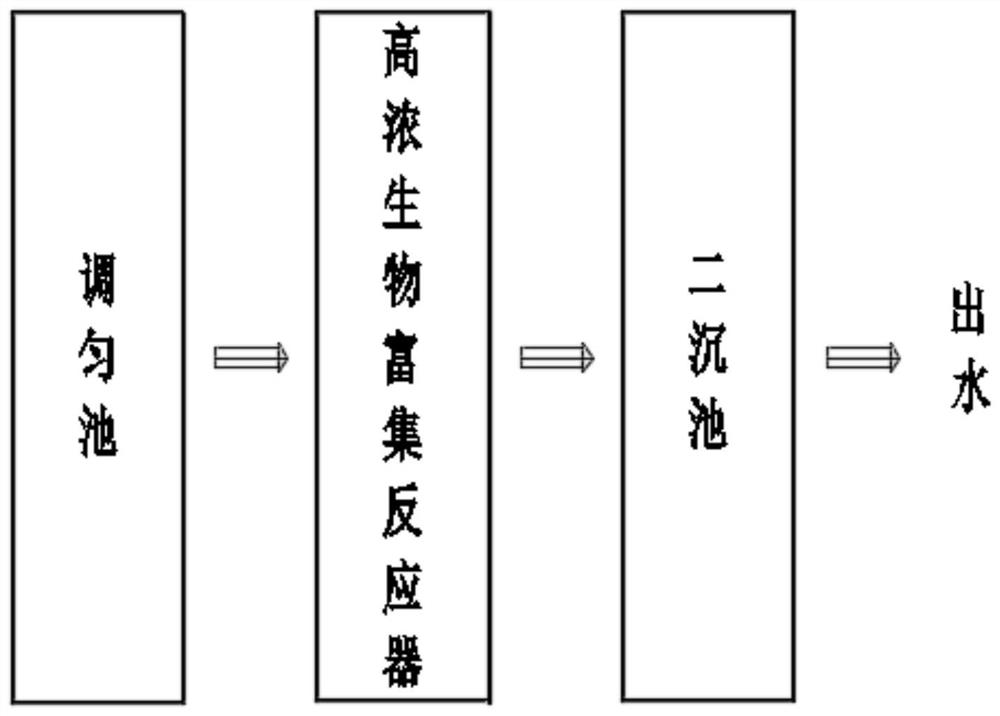

[0052] refer to figure 2 As shown, the second embodiment provides a method for the treatment of handmade rice wine wastewater, using the high-concentration biological enrichment reactor provided in the first embodiment, and the method includes the following steps:

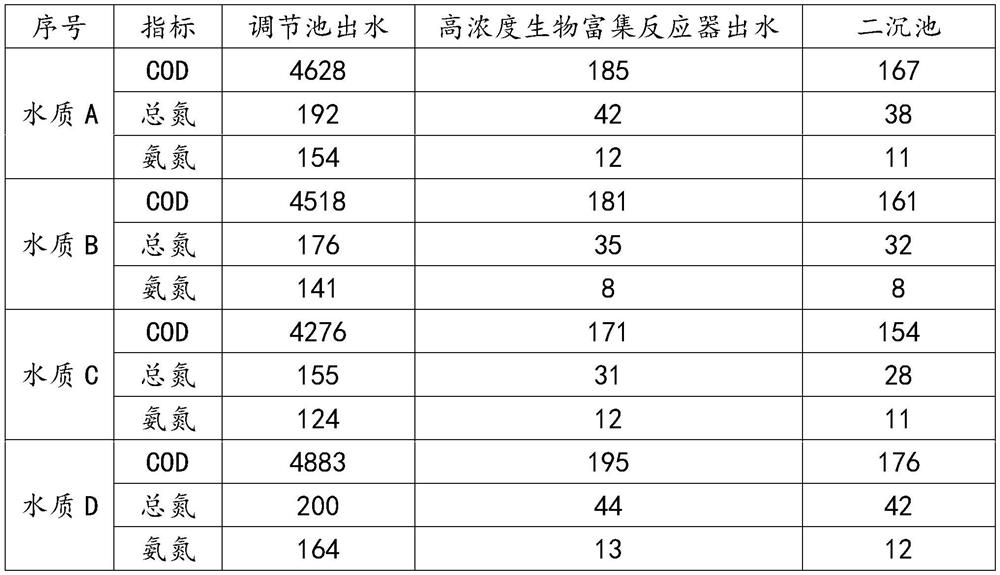

[0053] Step 1: After the handmade rice wine wastewater is pretreated, it enters the mixing tank for water quality mixing. The pretreatment measures are mainly coarse grilles and screens, etc., mainly to intercept impurities and reduce the treatment load of subsequent facilities. The effluent quality of this step is controlled as follows: COD is 4000-5000mg / L, ammonia nitrogen is 120-160mg / L, and total nitrogen is 150-200mg / L. The effluent enters the bioconcentration reactor with a B / C ratio greater than 0.4.

[0054] Step 2: The effluent from step 1 enters the high-concentration biological enrichment reactor for activated sludge and biofilm treatment, wherein the primary aerobic zone 3 and secondary aerobic zone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com