Method for continuously preparing 3, 3'-dichloro-4, 4'-diaminodiphenyl methane

A technology of diaminodiphenyl and methane, which is applied in 3 fields of continuous preparation, can solve the problems of unmentioned continuous post-treatment process, unstable product quality, limited capacity scale, etc. The effect of easy to change color in storage and expansion of production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

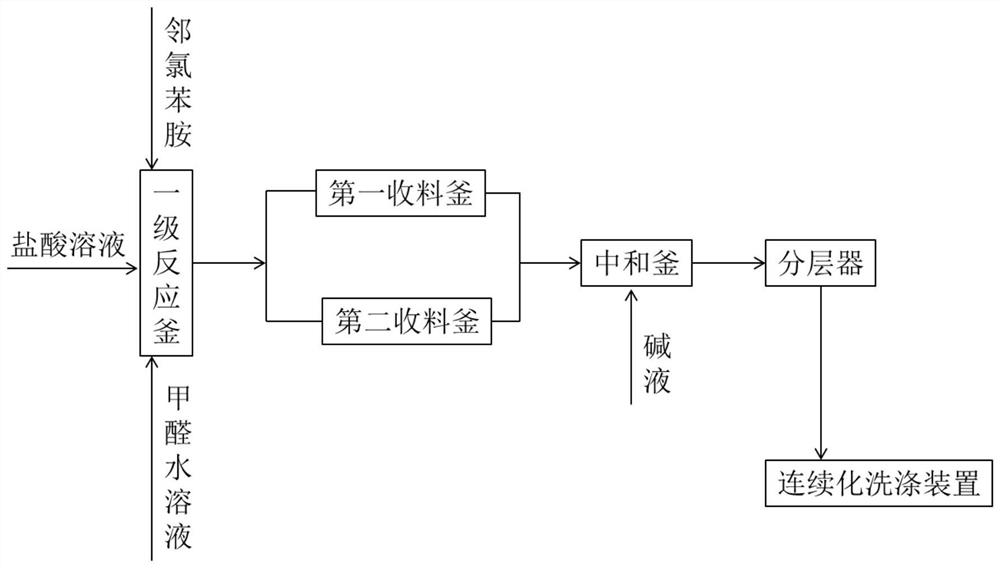

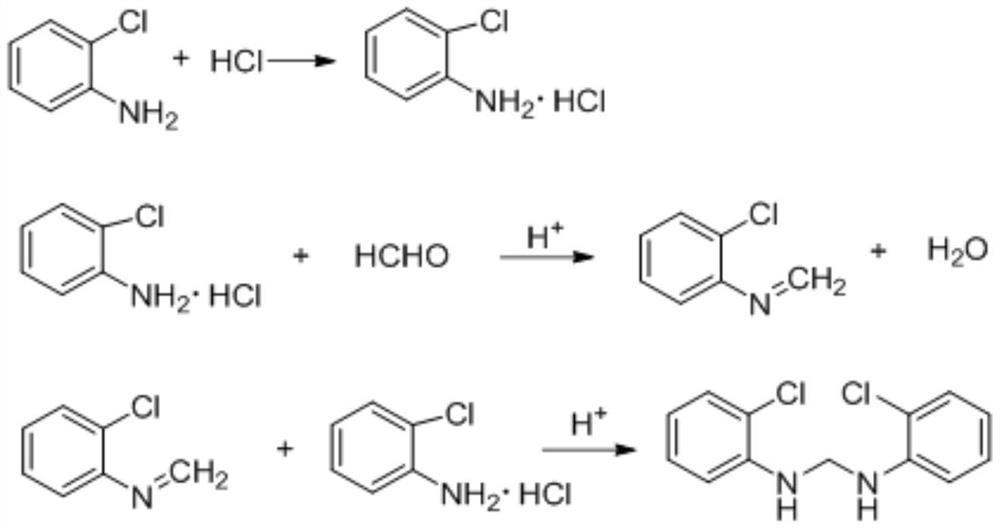

[0047] (1) Add 5110g of hydrochloric acid solution, 1276.3g of o-chloroaniline and 1500g of formaldehyde solution to the primary reaction kettle continuously and simultaneously, and carry out salt formation and condensation reaction at 50°C for 30min; wherein, the mass of hydrochloric acid in 5110g of hydrochloric acid solution The percentage concentration is 10%, containing 14mol of hydrochloric acid; the mass percent concentration of formaldehyde in 1500g formaldehyde aqueous solution is 10%, containing 5mol of formaldehyde; 1276.3g o-chloroaniline is analytically pure, and the purity is 99.9%; The ratio is 1.4:1:0.5;

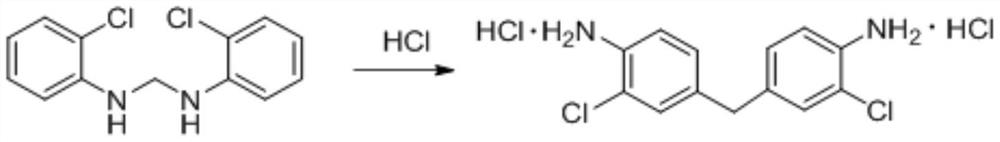

[0048] (2) The reaction solution in the first-stage reaction kettle obtained after the condensation reaction of the step (1) is continuously overflowed into the first collection kettle, and rearranged to generate MOCA hydrochloride. After the material collection of the material tank is completed, the overflow of the first-level reactor is switched to the seco...

Embodiment 2

[0053] (1) Add 3163.3g of hydrochloric acid solution, 1276.3g of o-chloroaniline and 1500g of formaldehyde solution to the primary reaction kettle continuously and simultaneously, and carry out salt formation and condensation reaction at 40°C for 60 minutes; among them, the hydrochloric acid in the 3163.3g of hydrochloric acid solution The mass percent concentration of 15% of formaldehyde contains 13mol of hydrochloric acid; the mass percent concentration of formaldehyde in 1500g formaldehyde aqueous solution is 10%, containing 5mol of formaldehyde; 1276.3g of o-chloroaniline is analytically pure, and its purity is 99.9%; The molar ratio is 1.3:1:0.5;

[0054] (2) The reaction solution in the first-stage reaction kettle obtained after the condensation reaction of the step (1) is continuously overflowed into the first collection kettle, and rearranged to generate MOCA hydrochloride. After the material receiving tank is finished, the overflow of the first-stage reactor is switch...

Embodiment 3

[0059] (1) 2190g of hydrochloric acid solution, 1276.3g of o-chloroaniline and 1200g of formaldehyde aqueous solution were added dropwise to the primary reaction kettle simultaneously respectively, and salt formation and condensation reaction were carried out at 30°C for 90min; wherein, the mass of hydrochloric acid in 2190g of hydrochloric acid solution The percentage concentration is 20%, containing 12mol of hydrochloric acid; the mass percent concentration of formaldehyde in 1200g formaldehyde aqueous solution is 15%, containing 6mol of formaldehyde; 1276.3g o-chloroaniline is analytically pure, and the purity is 99.9%; The ratio is 1.2:1:0.6;

[0060] (2) The reaction solution in the first-stage reaction kettle obtained after the condensation reaction of the step (1) is continuously overflowed into the first collection kettle, and rearranged to generate MOCA hydrochloride. After the material receiving tank is finished, the overflow of the first-stage reactor is switched to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com