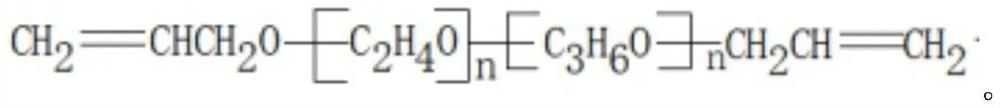

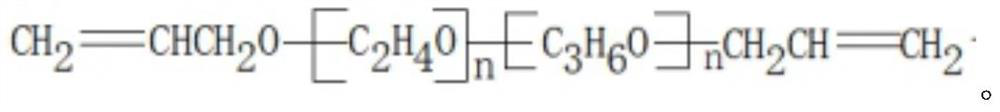

Amphiphilic allyl polymer for sewage treatment demulsifier and preparation method thereof

An allyl-based, sewage treatment technology, applied in separation methods, chemical instruments and methods, grease/oily substances/suspton removal devices, etc., can solve problems such as product quality decline, achieve low demulsification temperature, and environmental protection The meaning, the effect of the simple and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

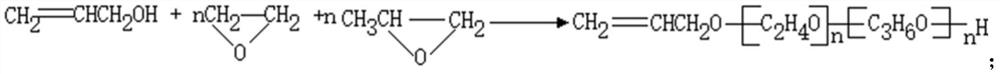

[0044] (1) Add potassium propylene alcoholate into a 3L stainless steel reaction kettle. After the oxygen content is replaced by nitrogen, suck allyl alcohol with a straw, start stirring, and the temperature is 30°C; heat up and dehydrate for half an hour, and the temperature is 35°C; use a slow speed at 35°C Add PO and EO, gradually raise the temperature to keep the polymerization reaction temperature at 90°C; then react with internal pressure for half an hour, the temperature is 90°C; cool down to 50°C, take a sample for inspection; refine after passing the test, add an adsorbent for post-treatment, and obtain a molecular weight of 500g / mol Propylene Glycol Ether.

[0045] (2) Add the calculated amount of propenol ether and sodium methoxide solution into the rotary thin film evaporator, and control the reaction temperature at 100±3°C. Vacuumize to remove the methanol in the sodium methoxide solution and the methanol generated in the alcohol exchange reaction. The demethanoli...

Embodiment 2

[0050] (1) Add potassium propylene alcoholate into a 3L stainless steel reaction kettle. After the oxygen content is replaced by nitrogen, suck allyl alcohol with a straw, start stirring, and the temperature is 30°C; heat up and dehydrate for half an hour, and the temperature is 35°C; use a slow speed at 35°C Add PO and EO, gradually raise the temperature to keep the polymerization reaction temperature at 90°C; then react with internal pressure for half an hour, the temperature is 90°C; cool down to 50°C, take a sample for inspection; refine after passing the test, add an adsorbent for post-treatment, and obtain a molecular weight of 500g / mol Propylene Glycol Ether.

[0051] (2) Add the calculated amount of propenol ether and sodium methoxide solution into the rotary thin film evaporator, and control the reaction temperature at 100±3°C. Vacuumize to remove the methanol in the sodium methoxide solution and the methanol generated in the alcohol exchange reaction. The demethanoli...

Embodiment 3

[0056] (1) Add sodium allyl alcohol into a 3L stainless steel reaction kettle. After the oxygen content is replaced by nitrogen, suck allyl alcohol with a straw, start stirring, and the temperature is 28°C; heat up and dehydrate for half an hour, and the temperature is 38°C; use a slow speed at 38°C Add PO and EO, gradually raise the temperature to keep the polymerization reaction temperature at 93°C; then react under internal pressure for half an hour, the temperature is 93°C; cool down to 50°C, take a sample for inspection; refine after passing the test, add an adsorbent for post-treatment, and obtain a molecular weight of 550g / mol Propylene Glycol Ether.

[0057] (2) Add the calculated amount of propenol ether and sodium methoxide solution into the rotary thin film evaporator, and control the reaction temperature at 110±3°C. Vacuumize to remove the methanol in the sodium methoxide solution and the methanol generated in the alcohol exchange reaction. The demethanolization te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com