Super-long service life self-repairing stress sensor based on printable nano composite material and preparation method thereof

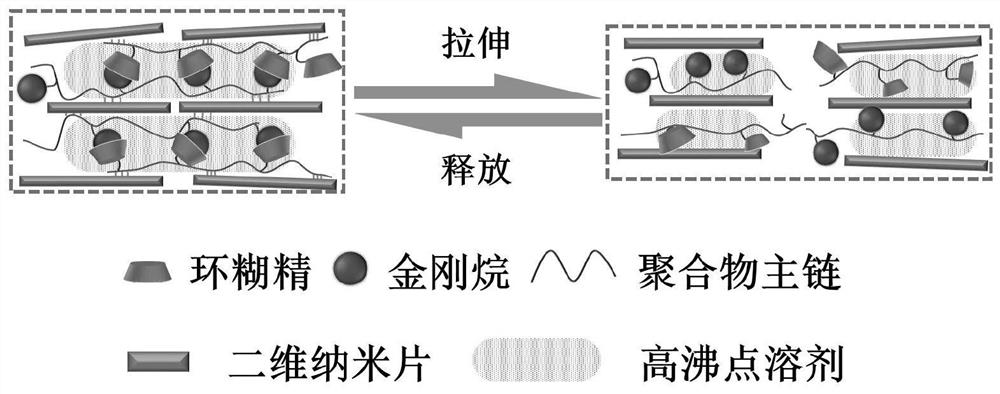

A technology of nano-composite materials and stress sensors, which is applied to the printing, printing, and printing processes of producing special varieties of printed matter. It can solve the problems of low sensitivity and self-repairing stress sensors that have not been reported yet, and achieve high sensitivity and working strain range. Wide, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Weigh 0.2 g of graphene oxide with a sheet size of about 1-2 μm prepared by a chemical method and place it in a beaker, add 100 mL of deionized water, and ultrasonicate for 30 minutes to obtain a 2 mg / mL graphene oxide dispersion. L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

[0030] (2) 1 g of polyvinyl alcohol, 455 mg of succinic anhydride, and 13 mg of p-toluenesulfonic acid were added to the DMSO solution, followed by stirring at 50° C. for 48 hours. Then, it was dialyzed in water for 5 days to remove impurities, and the solution was spin-dried to obtain PVAA as a white solid.

[0031] (3) Add 200mL of DMF, 500mg of PVAA, 96mg of amantadine, 53mg of N-(3-dimethylaminopropyl)-N'-ethylcarbodiimide hydrochloride into a 500mL round bottom flask equipped with a magnetic stirrer , 43mg of 1-hydroxybenzotriazole monohydrate and 55.8mg of N,N-diisopropylethylamine. Heat and stir at 70°C for 24 hours. The crude solution was dia...

Embodiment 2

[0038] (1) Weigh 0.2 g of MXene (Ti 3 C 2 X) Place in a beaker, add 100mL of deionized water, and sonicate for 30 minutes to obtain 2mg / mL of MXene(Ti 3 C 2 X) Dispersions.

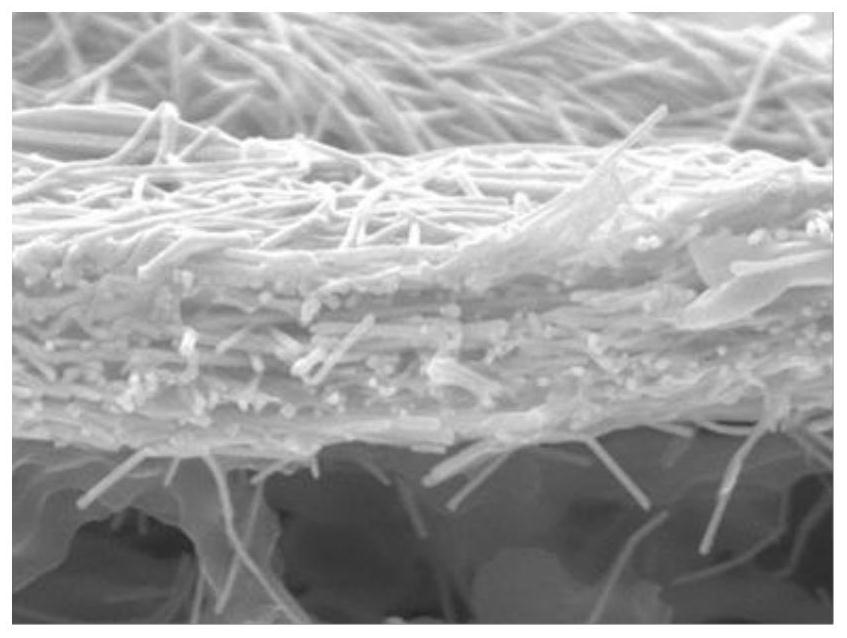

[0039] (2) Weigh 1mL silver nanowire (length 5μm, diameter 30-40nm) dispersion (15mg / mL) in reagent bottle, add 2.5mL step (1) to obtain MXene (Ti 3 C 2 X) solution, sonicated to redisperse it. Suction filter with microporous membrane, wash several times with deionized water, suck off the supernatant, and obtain MXene containing silver nanowires (Ti 3 C 2 X) Conductive gel.

[0040] (3) Add 200mL of DMF, 500mg of polyacrylic acid, 96mg of cucurbituril, and 53mg of N-(3-dimethylaminopropyl)-N'-ethylcarbodiimide hydrochloride into a 500mL round bottom flask equipped with a magnetic stirrer , 43mg of 1-hydroxybenzotriazole monohydrate and 55.8mg of N,N-diisopropylethylamine. Heat and stir at 70°C for 24 hours. The crude solution was dialyzed against deionized water for 5 days to remove impurities a...

Embodiment 3

[0046] (1) Weigh 0.2 g of graphene oxide with a sheet size of about 1-2 μm prepared by a chemical method and place it in a beaker, add 100 mL of deionized water, and ultrasonicate for 30 minutes to obtain a 2 mg / mL graphene oxide dispersion. L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

[0047] (2) Weigh 2mL of the silver nanowire (length 5μm, diameter 30-40nm) dispersion (10mg / mL) into the reagent bottle, add 2mL of the graphene oxide solution obtained in step (1), and ultrasonically oscillate to redisperse it . Suction filtration with a microporous membrane, washing with deionized water several times, and sucking off the supernatant to obtain a conductive gel containing silver nanowires and graphene oxide.

[0048] (3) Add 200 mL of DMF, 500 mg of polyacrylamide, 96 mg of column[6]arene, 53 mg of N-(3-dimethylaminopropyl)-N'-ethylcarbodiethylene into a 500 mL round bottom flask equipped with a magnetic stirrer Amine hydrochloride, 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com