Non-platinum-based transparent electrode material, preparation method and application thereof

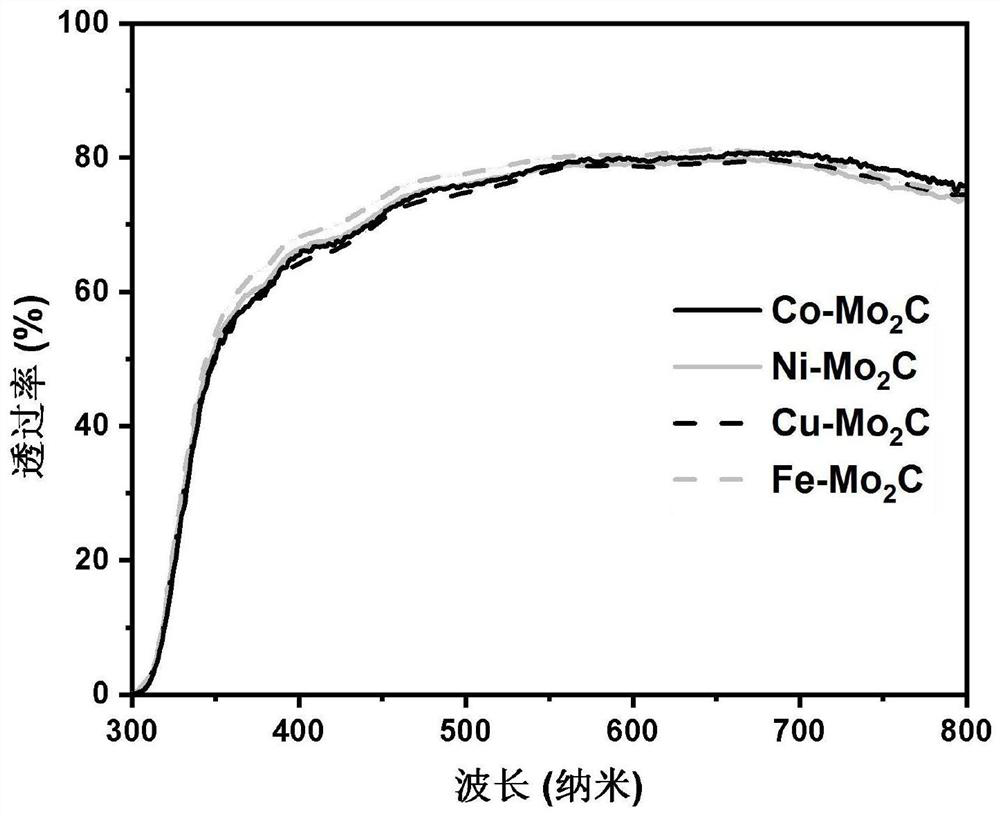

A transparent electrode, non-platinum-based technology, applied in the field of solar cells, can solve the problems of expensive Pt materials and low transmittance, achieve good permeability, high transmittance, and improve dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention provides a method for preparing a non-platinum-based transparent electrode material described in the above technical solution, comprising the following steps:

[0035] The molybdenum-based conductive carrier is used as a target to perform magnetron sputtering on the surface of the FTO substrate to obtain an FTO-molybdenum-based transparent conductive carrier film;

[0036] The FTO-molybdenum-based transparent conductive carrier film is immersed in a non-platinum transition metal salt solution and then calcined under a protective atmosphere to obtain a non-platinum-based transparent electrode material.

[0037] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0038] In the invention, the molybdenum-based conductive carrier is used as a target material to perform magnetron sputtering on the surface of the FTO substrate to obtain the FTO-moly...

Embodiment 1

[0077] The FTO substrate with a thickness of 2.2mm was ultrasonically cleaned in detergent, acetone and ethanol for 15 minutes, taken out, dried, and treated with ultraviolet and ozone irradiation for 15 minutes to obtain a pretreated FTO substrate;

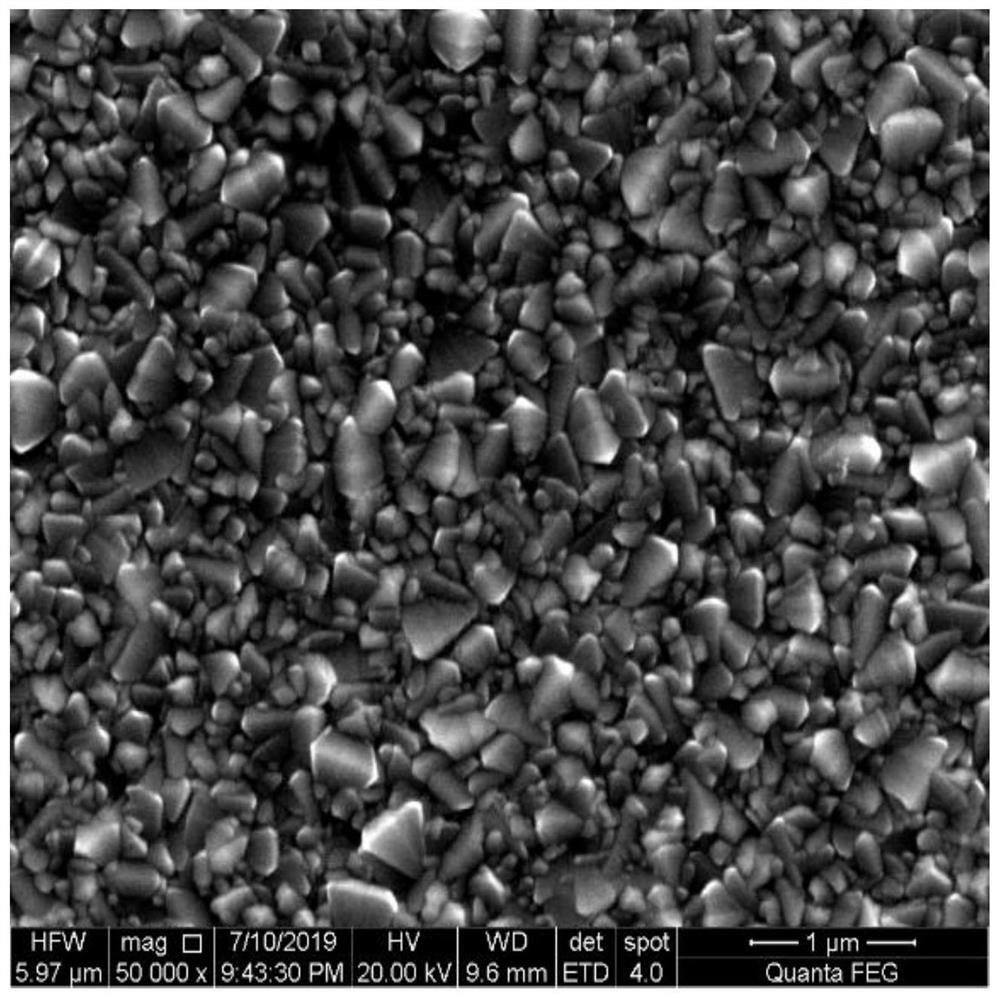

[0078] Place the pretreated FTO substrate in the magnetron sputtering chamber, and fix the Mo 2 For target C, pre-magnetron sputtering was performed for 5 minutes after closing the target baffle and substrate baffle, and after opening the target baffle and substrate baffle, magnetron sputtering was performed on the pretreated FTO substrate for 2 minutes, cooled to room temperature, A Mo with a thickness of about 15 nm was obtained 2 C conductive carrier film; the working parameters of the pre-magnetron sputtering and magnetron sputtering: Argon is the reaction gas, the pressure of the reaction gas is 0.8Pa, the power is 60W, and the temperature is 200°C;

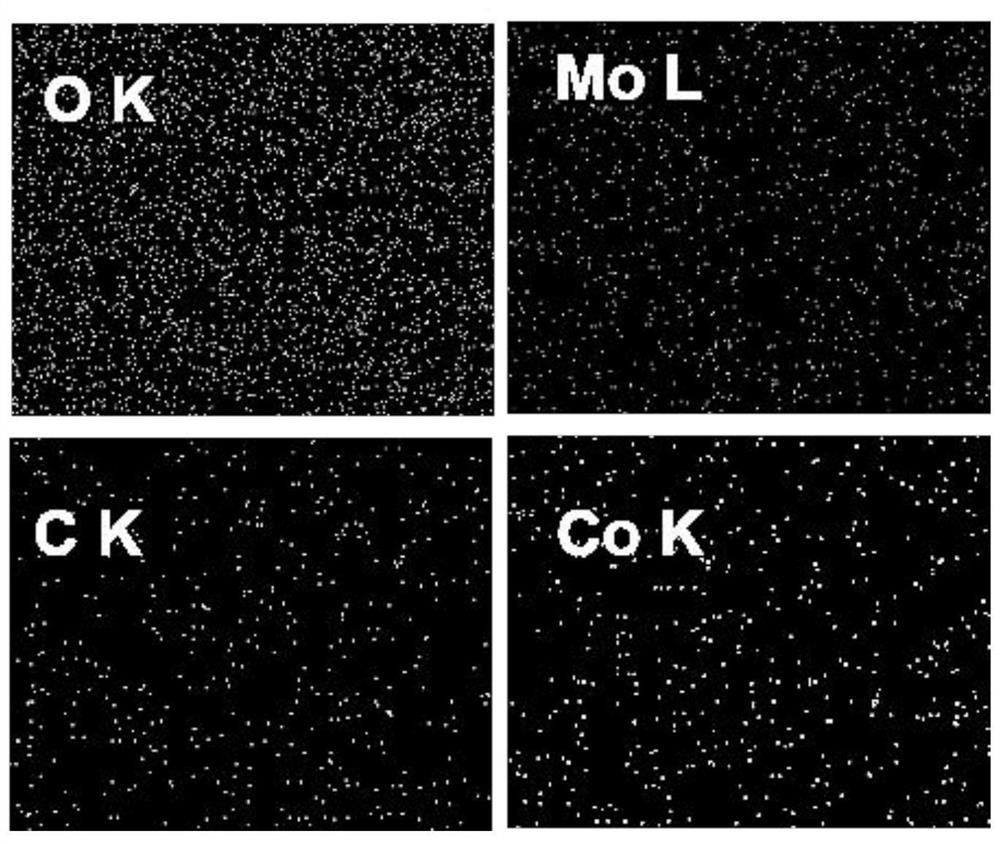

[0079] 0.0436g Co(NO 3 ) 2 ·6H 2 O and 15mL ultrapure water were stirr...

Embodiment 2

[0083] The non-platinum-based transparent electrode material was prepared according to the method of Example 1, the difference from Example 1 was that the cobalt nitrate aqueous solution was replaced by the cobalt nitrate ethanol solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com