Biochar-based composite material as well as preparation method and application thereof

A composite material and biochar technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as complex operation, unsuitable, large residue, etc., and achieve wide range of raw materials, wide application range, and purification The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

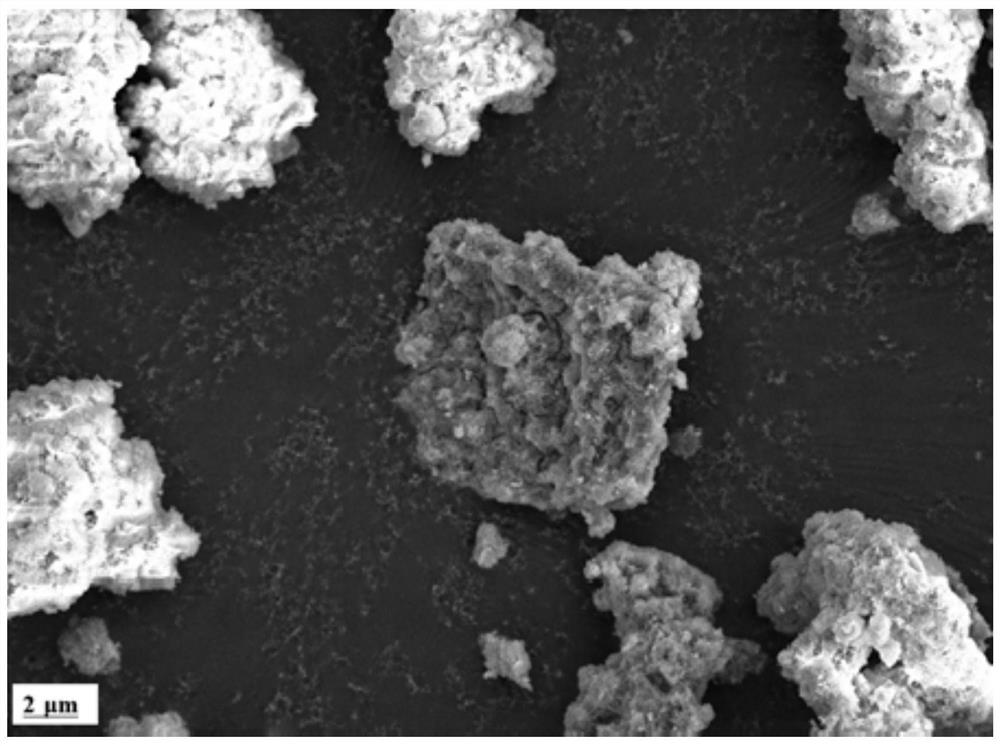

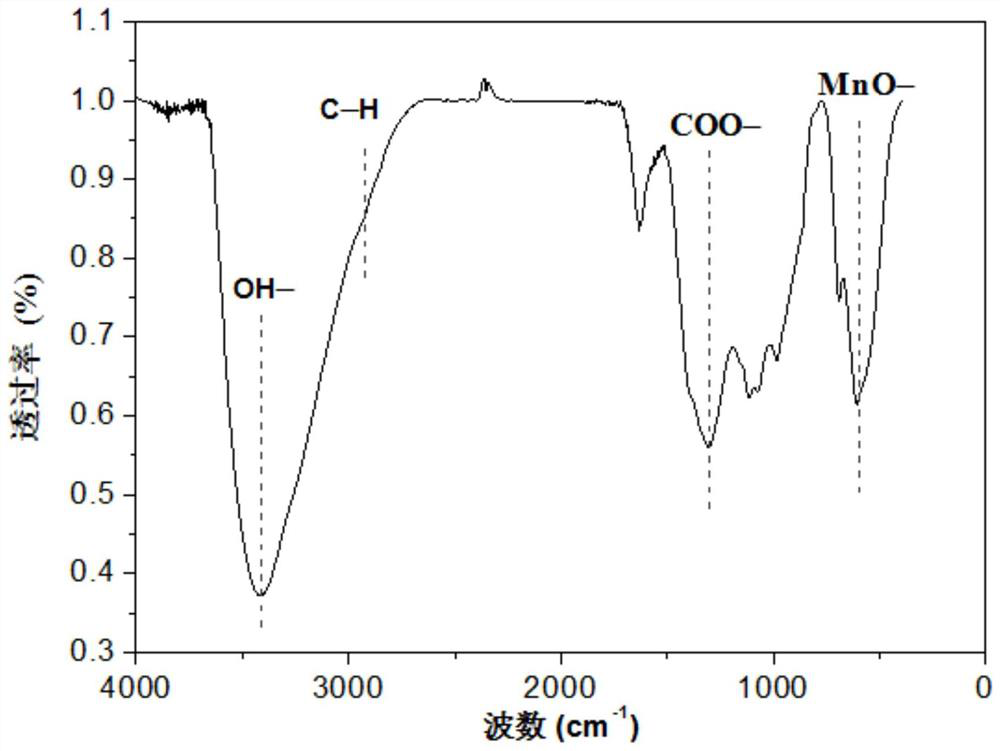

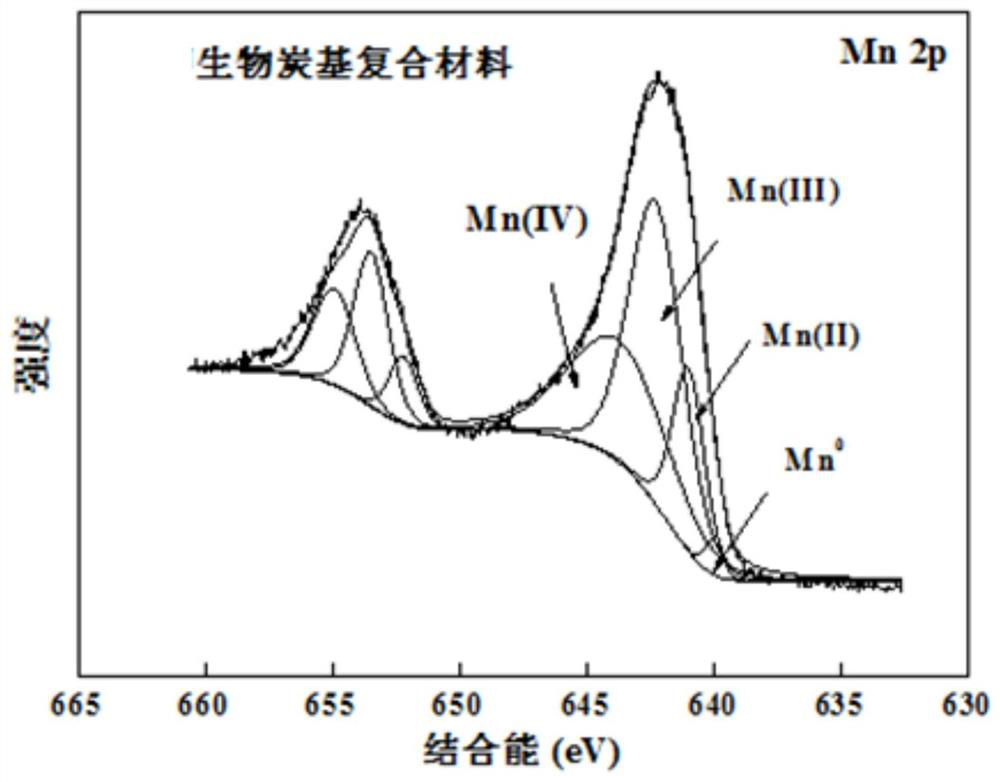

[0050] This example provides a biochar-based composite material, including: biochar containing potassium; and zero-valent manganese supported on the biochar containing potassium.

[0051] Wherein, the mass fraction of potassium in the potassium-containing biochar is 1-15 wt%. The mass fraction of zero-valent manganese is 0.5-25wt%.

Embodiment 2

[0053] This example provides a preparation method of a biochar-based composite material, comprising the following steps:

[0054] S1: Pyrolyzing the potassium-containing biomass raw material in an inert gas to obtain potassium-containing biochar;

[0055] S2: immerse the potassium-containing biochar obtained in step S1 in a sodium borohydride solution to react;

[0056] S3: adding the manganese salt solution into the mixed solution after the reaction in step S2, standing still after the reaction, separating the obtained precipitate, washing and drying the precipitate to obtain the biochar-based composite material.

[0057] Wherein, the potassium-containing biomass raw material includes at least one of watermelon peel, banana peel and cauliflower stalk. The mass fraction of potassium in watermelon peel, banana peel and cauliflower stalk usually meets 4-15%.

[0058] In step S1, the pyrolysis temperature is 450-600°C. The pyrolysis time is 1~5h. The pyrolysis is carried out ...

Embodiment 3

[0062] This example provides the application of biochar-based composite materials in the treatment of thallium-containing wastewater.

[0063] When the biochar-based composite material is used to treat thallium-containing wastewater, the dosage is preferably 0.2-3.0 g of the material per liter of thallium-containing wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com