Catalyst with function of purifying methylbenzene in air and preparation method thereof

A technology for purifying air and catalysts, which is applied in the field of catalysts for catalytic purification of toluene in the air and its preparation field, which can solve the problems of poor moisture resistance and high reaction temperature, achieve high thermal stability, improve the effect of not easy to lose, and promote the reaction process of toluene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

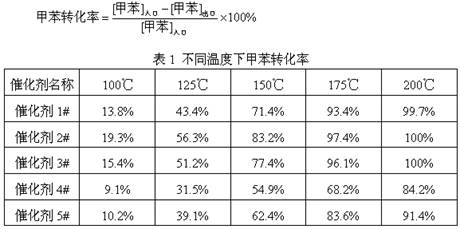

Examples

Embodiment 1

[0029] A kind of preparation method of the catalyst with purifying toluene function in air is realized by following steps:

[0030] (1) Preparation of cerium-iron composite oxide

[0031] Mix ferric nitrate solution and cerium sulfate solution at room temperature for 10 minutes, then add urea and CTAB and continue stirring for 30 minutes, treat the resulting mixed solution at 80°C for 24 hours, centrifuge, wash and dry the obtained product at 400°C Roasting treatment 6h; The ratio of the amount of substance of the iron nitrate and cerium sulfate is 0.25:1, the addition of the urea is 10 times of the total amount of the substance of the iron nitrate and cerium sulfate, the addition of the CTAB is nitric acid 5wt% of the total weight of iron and cerium sulfate; the molar concentration of ferric nitrate solution is 0.1mol / L, and the molar concentration of cerium sulfate solution is 0.4mol / L;

[0032] (2) Synthesis of ionic liquid precursor TEAPS

[0033] Add 1,3-propane sultone a...

Embodiment 2

[0039] A kind of preparation method of the catalyst with purifying toluene function in air is realized by following steps:

[0040] (1) Preparation of cerium-iron composite oxide

[0041] Mix ferric nitrate solution and cerium sulfate solution at room temperature for 20 minutes, then add urea and CTAB and continue stirring for 30 minutes, treat the resulting mixed solution at 90°C for 12 hours, centrifuge, wash, and dry the obtained product at 500°C Roasting treatment 4h; The ratio of the amount of the substance of the iron nitrate and cerium sulfate is 4:1, the addition of the urea is 20 times of the total amount of the substance of the iron nitrate and the cerium sulfate, and the addition of the CTAB is nitric acid 10wt% of the total weight of iron and cerium sulfate; the molar concentration of ferric nitrate solution is 0.4mol / L, and the molar concentration of cerium sulfate solution is 0.1mol / L;

[0042] (2) Synthesis of ionic liquid precursor TEAPS

[0043] Add 1,3-prop...

Embodiment 3

[0049] A kind of preparation method of the catalyst with purifying toluene function in air is realized by following steps:

[0050] (1) Preparation of cerium-iron composite oxide

[0051] Mix ferric nitrate solution and cerium sulfate solution at room temperature for 15 minutes, then add urea and CTAB and continue to stir for 30 minutes, treat the resulting mixed solution at 85°C for 18 hours, centrifuge, wash, and dry the obtained product at 450°C Roasting treatment for 5h; the ratio of the amount of iron nitrate and cerium sulfate is 1:1, the amount of urea added is 15 times that of the total amount of matter of iron nitrate and cerium sulfate, and the amount of CTAB added is nitric acid 7 wt% of the total weight of iron and cerium sulfate; the molar concentration of ferric nitrate solution is 0.25 mol / L, and the molar concentration of cerium sulfate solution is 0.25 mol / L;

[0052] (2) Synthesis of ionic liquid precursor TEAPS

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com