Photocatalytic oxidation device for printing and dyeing wastewater treatment

A technology for catalytic oxidation and printing and dyeing wastewater, which is applied in textile industry wastewater treatment, water/sewage treatment, special compound water treatment, etc. It can solve the problems of affecting the photocatalytic effect and reducing the photocatalytic effect, so as to improve the catalytic effect and improve the mixing effect. Effect, the effect of enhancing the bleaching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

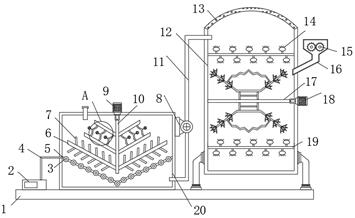

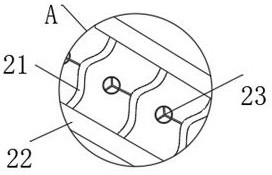

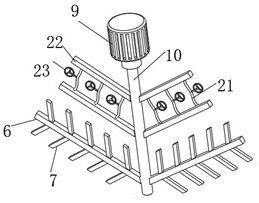

[0030] refer to Figure 1-4 , a photocatalytic oxidation device for printing and dyeing wastewater treatment, comprising a bottom plate 1, an ozone generator 2 and a bleaching box 20 are fixed on the top outer wall of the bottom plate 1 by screws, and the inner wall of the bleaching box 20 is provided with an air distribution pipe 3, and the air distribution pipe 3 The outer wall is provided with equidistant aeration pans 5, and the inner wall of one side of the air distribution pipe 3 and the output end of the ozone generator 2 are connected with the same first conduit 4 through a flange, the air distribution pipe 3 is a V-shaped structure, and the bleaching box The top outer wall of 20 is fixed with the first motor 9 by screws, and the output shaft of the first motor 9 is connected with the first rotating rod 10 through a coupling, and the first stirring rod 6 is welded on both sides of the outer wall of the first rotating rod 10 , and both sides of the outer wall of the fir...

Embodiment 2

[0039] refer to Figure 5 , a photocatalytic oxidation device for printing and dyeing wastewater treatment. Compared with Embodiment 1, this embodiment also includes an adhesive layer 29 arranged on the inner wall of the catalytic oxidation tank 12, and an aluminum foil layer is arranged on the outer wall of the adhesive layer 29. 30.

[0040] Connect the equipment to the power supply, firstly add the printing and dyeing wastewater and bleaching agent into the bleaching tank 20 respectively, turn on the ozone generator 2 and the first motor 9, and the ozone generator 2 passes into the bleaching tank through the air distribution pipe 3 and the aeration disc 5 Ozone, the first stirring rod 6 and the first stirring block 7 fully mix the waste water and the ozone, the elastic rope 21 and the stirring frame 23 fully mix the waste water and the bleaching agent, open the water pump 8, and the bleached waste water is added to the In the catalytic oxidation tank 12, the catalyst is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com