Carboxyl nitrile rubber/carboxyl starch composite material as well as preparation method and application thereof

A technology of carboxylated nitrile rubber and carboxylated starch, which is applied in the field of carboxylated nitrile rubber/carboxylated starch composite material and its preparation, can solve the problems of difficult recycling and reprocessing, non-degradable, etc., and achieve good repeatable thermoplastic processing performance, The effect of low cost, green environmental protection and biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

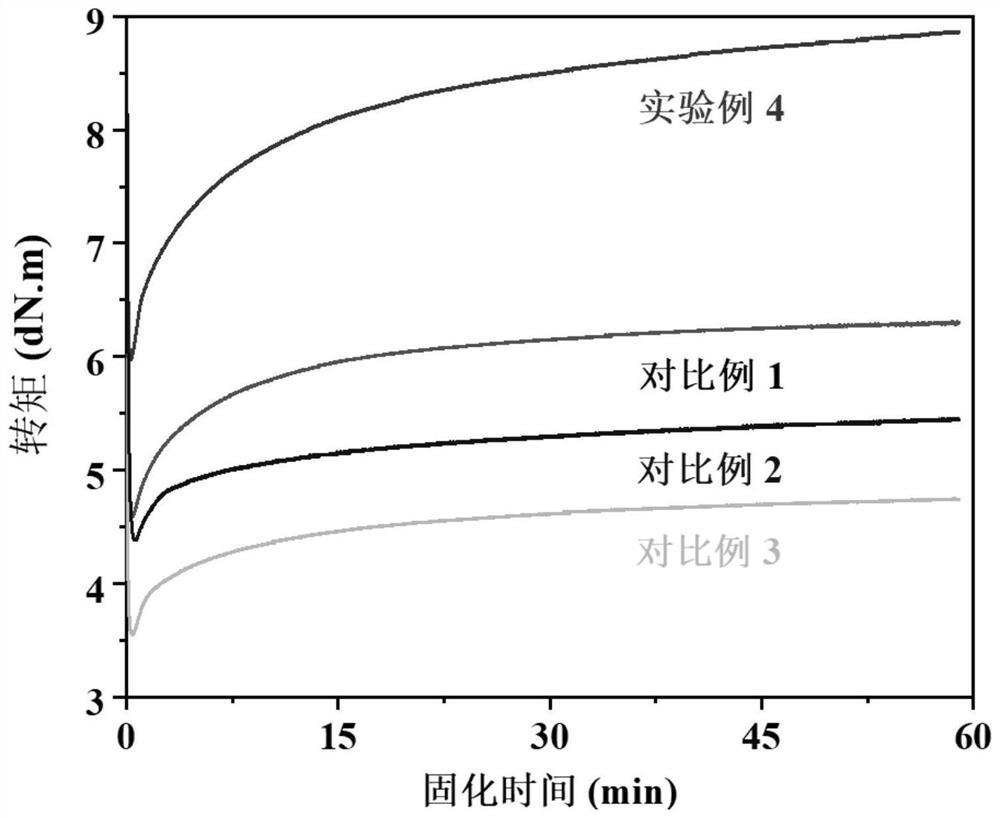

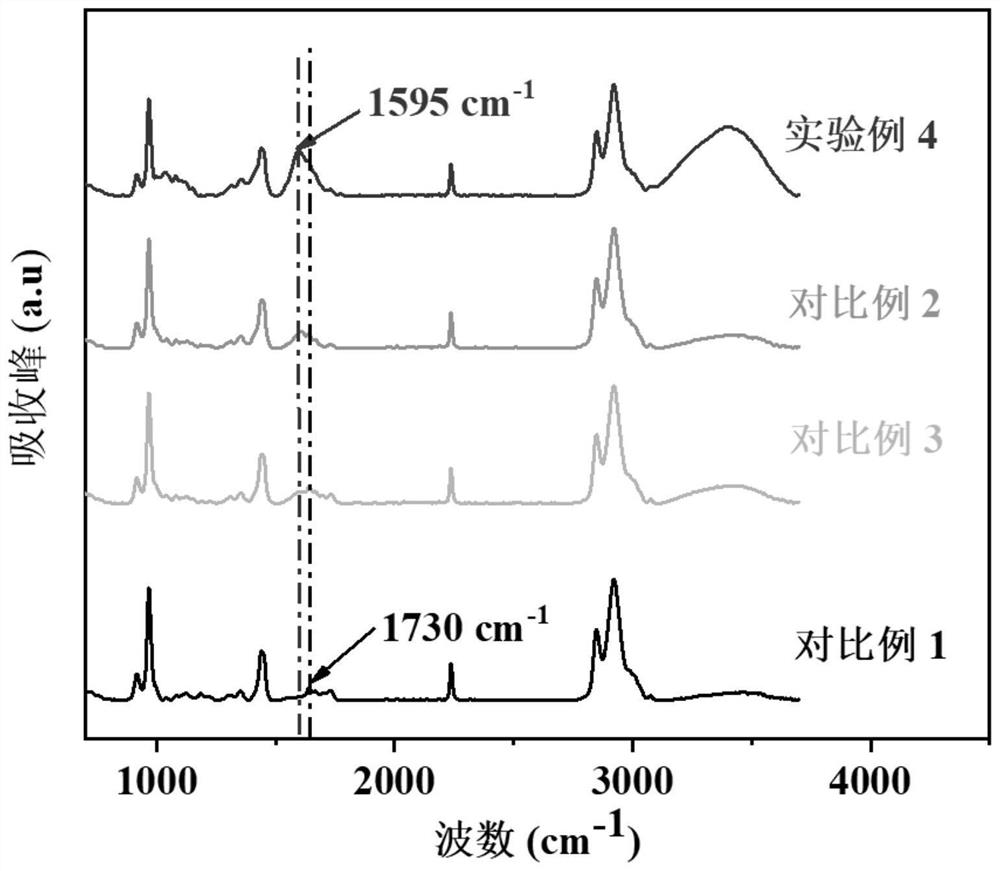

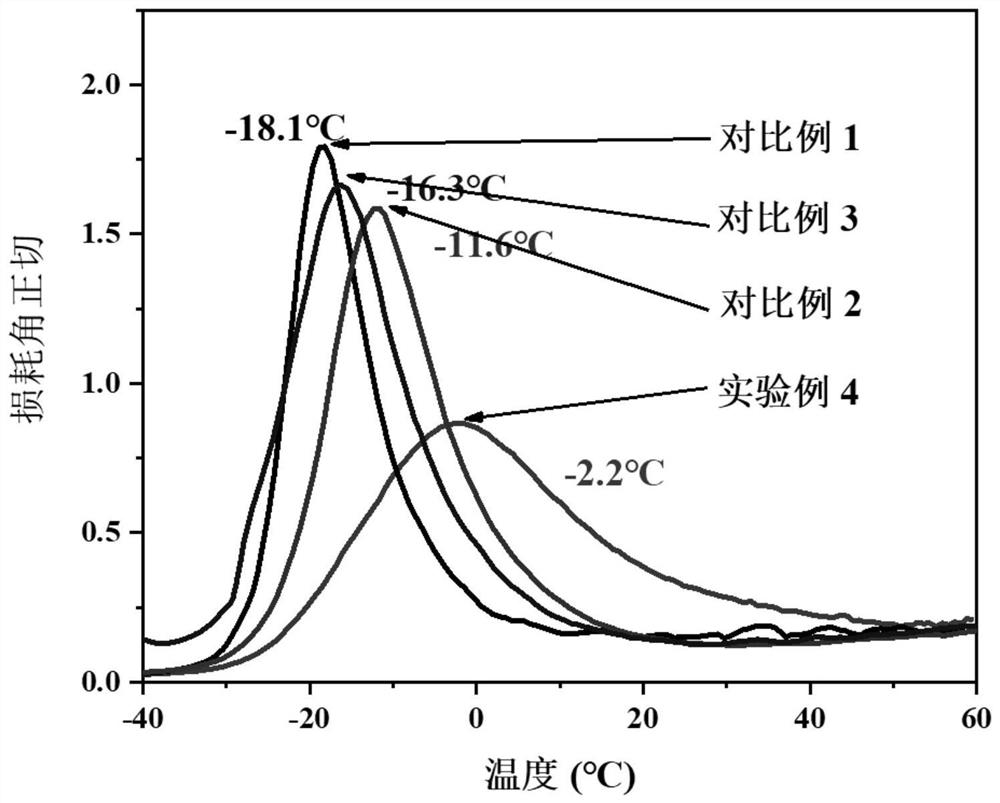

Embodiment 1

[0034] Dissolve 500 g of starch in 2500 g of deionized water, then mix uniformly under mechanical stirring at 1000 r / min, put the mixed starch solution in a microwave oven for gelatinization, and cool to room temperature. Add 352g of 30% hydrogen peroxide solution and 200mg of anhydrous copper sulfate as a catalyst. After 24 hours of constant temperature reaction at 35℃, the resulting carboxy starch (OST) syrup is placed in a blast oven at 60℃. Carboxy starch (OST) is dried to constant weight and crushed to 200 mesh powder for later use. Weigh 50g of carboxyl starch (OST) powder, add 300g of water, pour into 2000g of carboxyl nitrile butadiene rubber (XNBR) emulsion with a solid content of 40%, then mechanically stir (1000r / min) for 40 minutes, then pour into stainless steel iron Place the pan in a 60°C blast oven and bake for 2 hours. Then, the above-mentioned mixture is processed in an open mill, and 12g of zinc oxide with a particle diameter of 30nm is added at the same tim...

Embodiment 2

[0036] Dissolve 500 g of starch in 2500 g of deionized water, then mix uniformly under mechanical stirring at 1000 r / min, put the mixed starch solution in a microwave oven for gelatinization, and cool to room temperature. Add 176g of 30% hydrogen peroxide solution and 150mg of anhydrous copper sulfate as a catalyst. After 36 hours of constant temperature reaction at 35℃, the carboxyl starch (OST) paste is placed in a 60℃ blast oven. Carboxy starch (OST) is dried to constant weight and crushed to 200 mesh powder for later use. Weigh 35g of carboxyl starch (OST) powder, add 200g of water, pour into 350g carboxyl nitrile butadiene rubber (XNBR) emulsion with a solid content of 40%, then mechanically stir (1000r / min) for 50 minutes, then pour into stainless steel iron Put the pan in a 65°C blast oven and bake it for 2.5 hours. Then the above-mentioned mixture is processed in an open mill, and 14g of zinc oxide with a particle diameter of 40nm is added at the same time. After 45 mi...

Embodiment 3

[0038] Dissolve 500 g of starch in 2200 g of deionized water, then mix uniformly under mechanical stirring at 1000 r / min, put the mixed starch solution in a microwave oven for gelatinization, and cool to room temperature. Add 528g of 30% hydrogen peroxide solution and 350mg of anhydrous copper sulfate as a catalyst. After reacting at 35℃ for 40 hours, put the carboxyl starch (OST) paste in a 60℃ blast oven. Carboxy starch (OST) is dried to constant weight and crushed to 200 mesh powder for later use. Weigh 30g carboxyl starch (OST) powder powder, add 150g of water, pour into 342g carboxyl nitrile butadiene rubber (XNBR) emulsion with a solid content of 40%, then mechanically stir (1000r / min) for 45 minutes, then pour into stainless steel Put the iron pan in a 65°C blast oven and bake it for 2 hours. Then, the above mixture was processed in an open mill and 10g of zinc oxide with a particle diameter of 30nm was added. After 40 minutes, the obtained sample was pressed in a flat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com