Transparent backboard for packaging solar cell

A solar cell and transparent technology, applied in the field of solar cells, can solve the problems of low transmittance of UV-resistant PET, inability to effectively improve the transmittance of the back sheet, delamination failure, etc., and achieve excellent UV resistance and heat and humidity resistance, Effective long-term UV shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

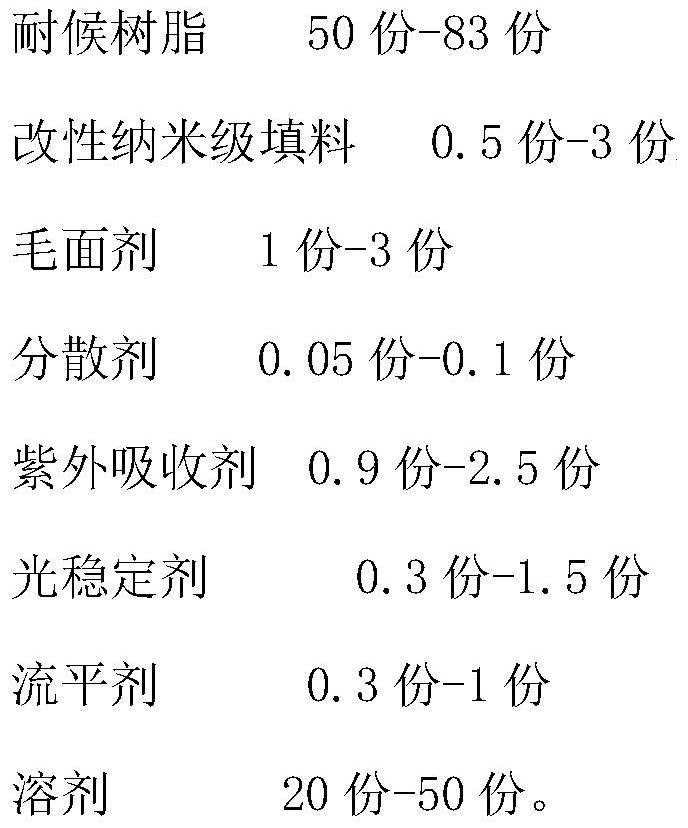

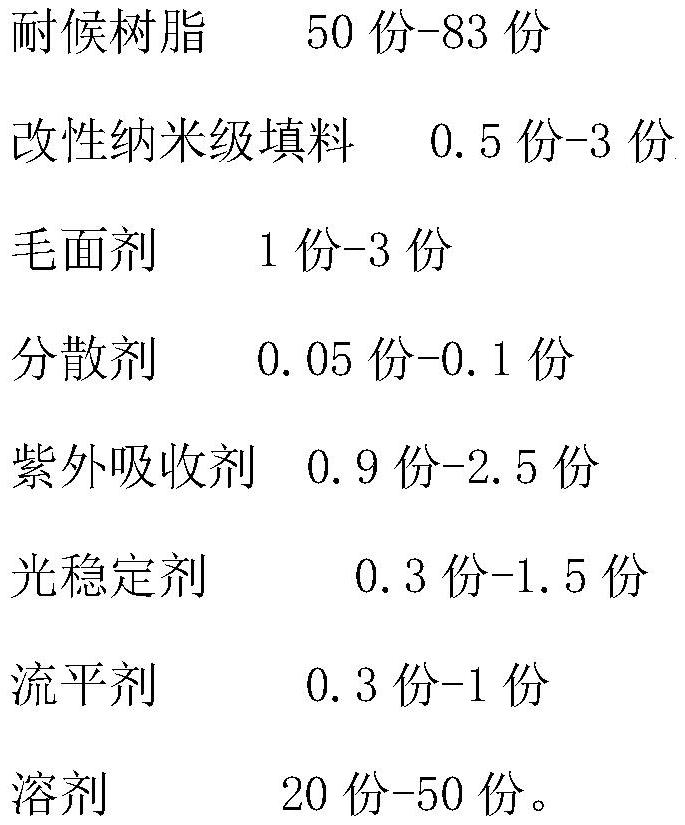

Method used

Image

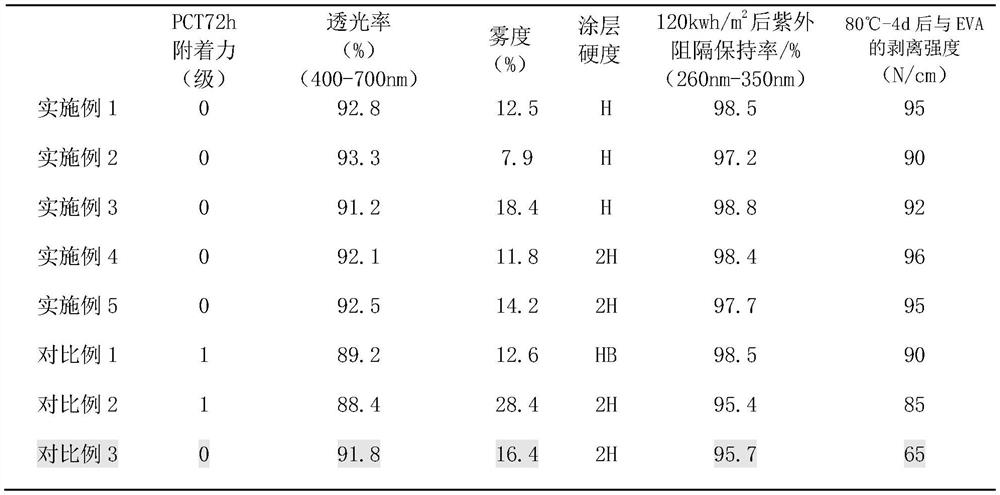

Examples

Embodiment 1

[0030] Coating liquid formula: take fluorocarbon resin (GK-570) 30g, acrylic resin (Haina HN-2604) 10g, butyl acetate 55g, nano-scale filler TiO 2 (Meililian RCL69) 0.9g, fumed silica (OK607) 2.4g, dispersant (BYK2155) 0.024g, UV absorber (UV-384) 1.5g, light stabilizer (Chimassorb 944) 0.5g, anti-hydrolysis agent (Stabaxol I type) 0.5 g, high shear dispersion to obtain a coating liquid A part, add 4.2 g of isocyanate (N3390), stir evenly to obtain a transparent coating liquid.

[0031] The manufacturing method of the back plate: apply 30% transparent adhesive layer coating solution on one side of the PET, and dry it at 140°C for 2 minutes; the adhesive thickness is 10 μm; the other side of the PET is compounded with a transparent PVF with a dry thickness of 25 μm , the samples were tested for performance after being aged at 50°C for 3 days.

Embodiment 2

[0033] Coating liquid formula: take 36g of fluorocarbon resin (Changxing 41011), 4g of acrylic resin (Jiangsu Sanmu 962), 50g of butyl acetate, nano-scale filler TiO 2 (Meililian RCL69) 0.1g, fumed silica (OK520) 1.2g, dispersant (BYK2155) 0.048g, UV absorber (UV-1577) 1.92g, light stabilizer (Chimassorb 944) 1.2g, anti-hydrolysis agent (Stabaxol I type) 0.5 g, high shear dispersion to obtain the coating liquid A part, add isocyanate (N3370) 10.18 g, stir evenly to obtain a transparent coating liquid.

[0034] The manufacturing method of the back plate: apply 25% transparent adhesive layer coating solution on one side of the PET, and dry it at 140°C for 2 minutes; the bonding thickness is 5 μm; the other side of the PET is compounded with transparent PVDF with a dry thickness of 25 μm , the samples were tested for performance after being aged at 50°C for 3 days.

Embodiment 3

[0036] Coating liquid formula: take 20g of fluorocarbon resin (Changxing 41011), 20g of acrylic resin (Changxing 73331-S-60), 25g of butyl acetate, nano-scale filler TiO 2(Meililian RCL69) 2.4g, fumed silica (ACEMATT 3600) 0.48g, dispersant (BYK2155) 0.072g, ultraviolet absorber (UV-400) 0.48g, light stabilizer (Chimassorb 944) 0.14g, anti-hydrolysis 0.5 g of the agent (Stabaxol I type) was dispersed with high shear to obtain the coating liquid A part, 6.5 g of isocyanate (N3790) was added, and the mixture was evenly stirred to obtain a transparent coating liquid.

[0037] The production method of the back plate: apply 40% transparent adhesive layer coating solution on one side of the PET, and dry it at 140 ° C for 2 minutes; the adhesive thickness is 20 μm; the other side of the PET is compounded with a transparent coating with a dry thickness of 25 μm. layer (formulation of adhesive layer coating liquid formulation), and the performance of the sample was tested after aging a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com