Preparation method for antibacterial and antiviral protective material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

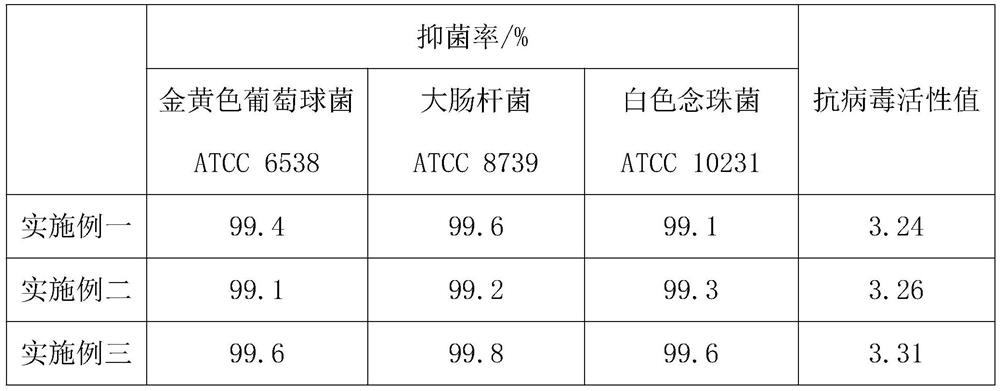

Examples

Embodiment 1

[0023] A preparation method for an antibacterial and antiviral protection material, comprising the following steps:

[0024] (1) Add polyvinyl alcohol and polylysine to deionized water at 90°C, stir and dissolve to prepare solution A with a mass fraction of 8%, and the mass ratio of polyvinyl alcohol to polylysine is 8:1 ;

[0025] (2) Dissolve natural plant extract, polyether modified silicone oil softener, and Tween-80 in N,N-dimethylformamide to prepare solution B. The natural plant extract, polyether modified The mass ratio of silicone oil softener, Tween-80, and N,N-dimethylformamide is 5:0.4:0.6:50;

[0026] The preparation method of the natural plant extract is as follows: first mix and pulverize 15 parts by weight of Scutellaria baicalensis, 5 parts by weight of Sophora flavescens, 3 parts by weight of Perilla leaves, and 6 parts by weight of Forsythia, then add deionized water with 10 times the weight of the powder, Ultrasonic extraction for 80 minutes, and the filt...

Embodiment 2

[0030] A preparation method for an antibacterial and antiviral protection material, comprising the following steps:

[0031] (1) Add polyvinyl alcohol and polylysine to deionized water at 95°C, stir and dissolve to prepare solution A with a mass fraction of 10%, and the mass ratio of polyvinyl alcohol to polylysine is 10:1 ;

[0032] (2) Dissolve the natural plant extract, polyether modified silicone oil softener, and AEO-9 in dimethyl sulfoxide to prepare solution B. The natural plant extract, polyether modified silicone oil softener, AEO -9. The mass ratio of dimethyl sulfoxide is 8:0.8:1.2:60;

[0033] The preparation method of the natural plant extract is as follows: first mix and pulverize 25 parts by weight of Scutellaria baicalensis, 6 parts by weight of Sophora flavescens, 5 parts by weight of Perilla leaves, and 9 parts by weight of Forsythia, then add deionized water with 10 times the weight of the powder, Ultrasonic extraction for 120min, the filtered filtrate is ...

Embodiment 3

[0037] A preparation method for an antibacterial and antiviral protection material, comprising the following steps:

[0038] (1) Add polyvinyl alcohol and polylysine to deionized water at 100°C, stir and dissolve to prepare solution A with a mass fraction of 12%, and the mass ratio of polyvinyl alcohol to polylysine is 12:1 ;

[0039] (2) Dissolve natural plant extract, polyether modified silicone oil softener, OP-10 in ethylene glycol, and prepare solution B. The natural plant extract, polyether modified silicone oil softener, OP-10 , The mass ratio of ethylene glycol is 10:1.2:2:80;

[0040] The preparation method of the natural plant extract is as follows: first mix and pulverize 30 parts by weight of Scutellaria baicalensis, 8 parts by weight of Sophora flavescens, 6 parts by weight of Perilla leaves, and 12 parts by weight of Forsythia, then add deionized water with 10 times the weight of the powder, Ultrasonic extraction for 150min, the filtered filtrate is then subjec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com