High-safety composite diaphragm and preparation method thereof

A composite diaphragm and a safe technology, applied in the field of high-safety composite diaphragm and its preparation, can solve the problems such as the inability to effectively suppress the chain reaction of internal short circuit, and achieve the effects of avoiding battery thermal runaway, inhibiting heat accumulation, and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

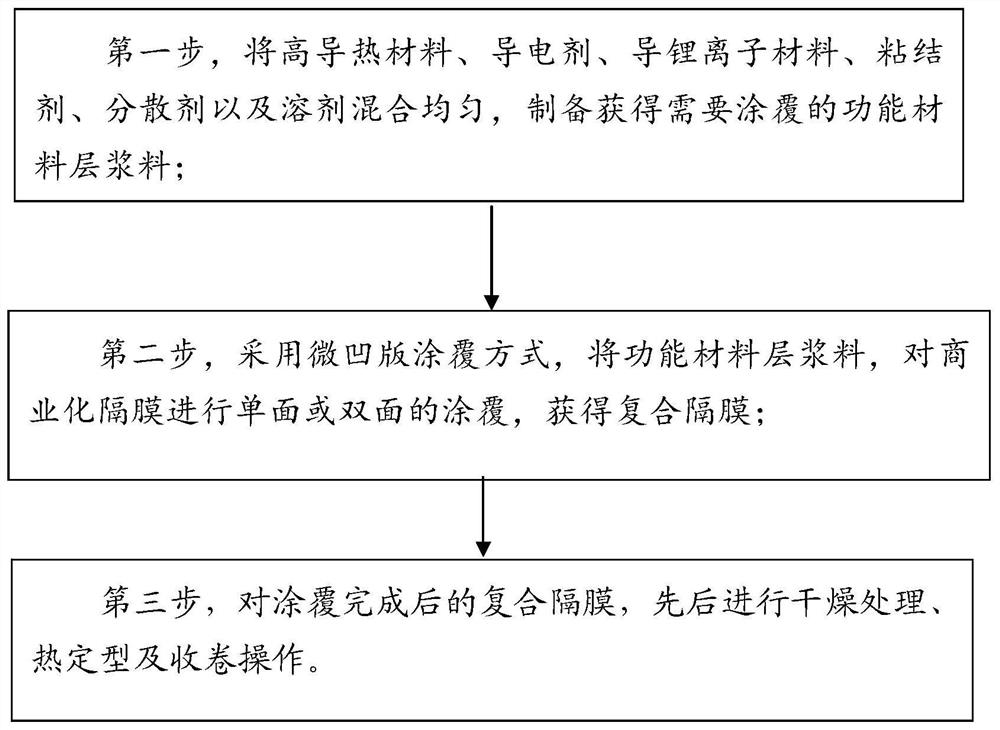

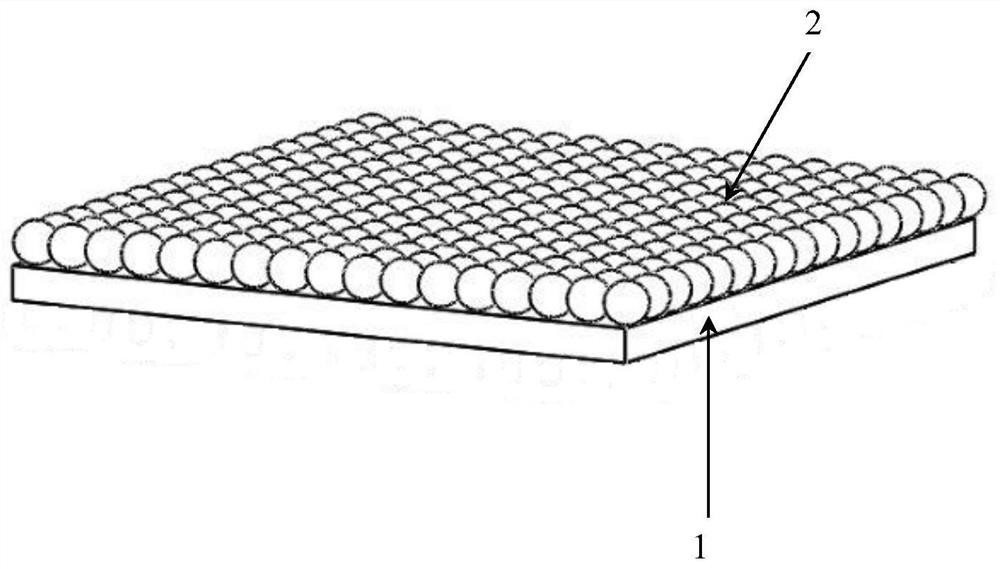

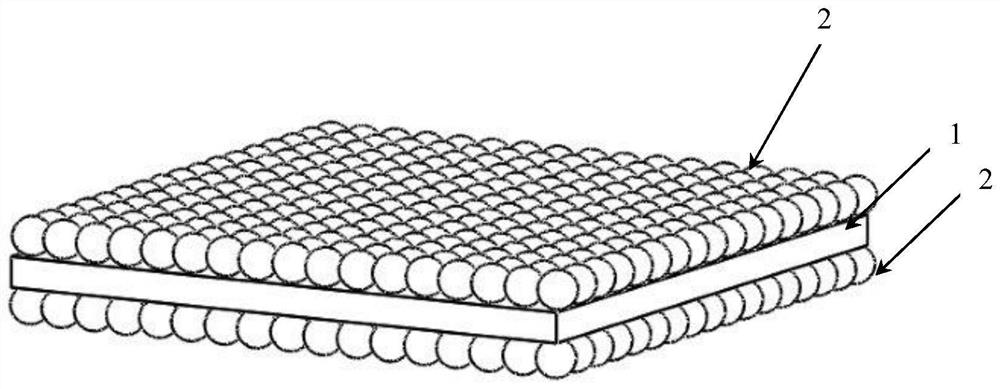

[0087] In order to prepare the high-safety composite diaphragm provided by the present invention above, see figure 1 Shown, the present invention also provides a kind of preparation method of high safety composite diaphragm, comprises the following steps:

[0088] The first step is to mix the high thermal conductivity material, conductive agent, lithium ion conductive material, binder, dispersant and solvent evenly, and prepare the functional material layer slurry to be coated;

[0089] The second step is to use the micro-gravure coating method to coat the functional material layer slurry on one or both sides of the commercial diaphragm to obtain a composite diaphragm;

[0090] In the third step, the coated composite diaphragm is successively subjected to drying treatment, heat setting and winding operations.

[0091] It should be noted that the micro-gravure coating method is an existing common slurry coating method, and will not be repeated here.

[0092] It should be note...

Embodiment 1

[0115]A kind of preparation method of high security composite diaphragm provided by the present invention, the steps are as follows:

[0116] In the first step, a polyethylene (PE) separator with a thickness of 12 microns is selected as the coating base film. The coating slurry was prepared by using inorganic nano-thermal conductive material (hexagonal boron nitride), lithium lanthanum zirconate LLZO (as a lithium ion conducting material), carbon nanotube CNT, binder PAN, dispersant PVP, solvent NMP, etc. Wherein, the percentage by weight of solid raw materials for the coating slurry is as follows: 40% for inorganic nano heat-conducting material, 35% for LLZO, 5% for CNT, 15% for binder, and 5% for dispersant. The solvent of the slurry is NMP, and the solid content of the slurry is 10%. Use a centrifugal disperser to fully mix and disperse the above mixture evenly to obtain a mixed slurry;

[0117] The second step is to use the micro-gravure coating method to coat the separa...

Embodiment 2

[0120] A kind of preparation method of high security composite diaphragm provided by the present invention, the steps are as follows:

[0121] In the first step, a 16-micron thick polypropylene (PP) separator is selected as the coating base film. Use inorganic nano-thermal conductive materials (mixed materials of hexagonal boron nitride and alumina), lithium aluminum titanium phosphate LATP (as a lithium ion conductive material), graphene, binder PAN, dispersant PVP, solvent NMP, etc. to prepare coating slurry material. The percentage by weight of the solid raw materials for the coating slurry is as follows: 50% for the inorganic nano thermally conductive material, 30% for LATP, 5% for graphene, 13% for the binder, and 2% for the dispersant. The solvent of the slurry is NMP, and the solid content of the slurry is 15%. Use a centrifugal disperser to fully mix and disperse the above mixture evenly to obtain a mixed slurry;

[0122] The second step is to use the micro-gravure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com