Preparation method of cyanobacteria charcoal material capable of efficiently adsorbing riboflavin and application threof

A riboflavin and biochar technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc., can solve the problems of high preparation cost, insufficient riboflavin adsorption capacity, and insufficient raw material sources , to achieve high adsorption function and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] A preparation method of a cyanobacteria biochar material with high-efficiency adsorption of riboflavin, comprising the following steps:

[0018] Step (1), pass the salvaged cyanobacteria through a 20-mesh sieve, then dry in an oven at 105°C to obtain blocky cyanobacterial biomass, and then pulverize the blocky cyanobacterial biomass with a pulverizer to obtain powdered cyanobacterial biomass;

[0019] Step (2), mix the powdered cyanobacterial biomass and KOH according to the mass ratio of 1:1, wrap it in tin foil, and place it in a tube furnace for pyrolysis to obtain a pyrolysis product; wherein, the pyrolysis conditions are as follows: pyrolysis at 800°C for 3 hours ;Heating rate: 10℃ / min; Atmosphere in tube furnace: inert gas N 2 ;

[0020] Step (3), wash the pyrolysis product with 5% hydrochloric acid, neutralize the KOH in the pyrolysis product, then use the circulating water pump to filter the filter cup to pass through the 0.45um membrane, trap the solid on the ...

specific Embodiment 1

[0022] The prepared cyanobacteria biochar material is used to recover the valuable component riboflavin in the solution, and the specific steps are as follows:

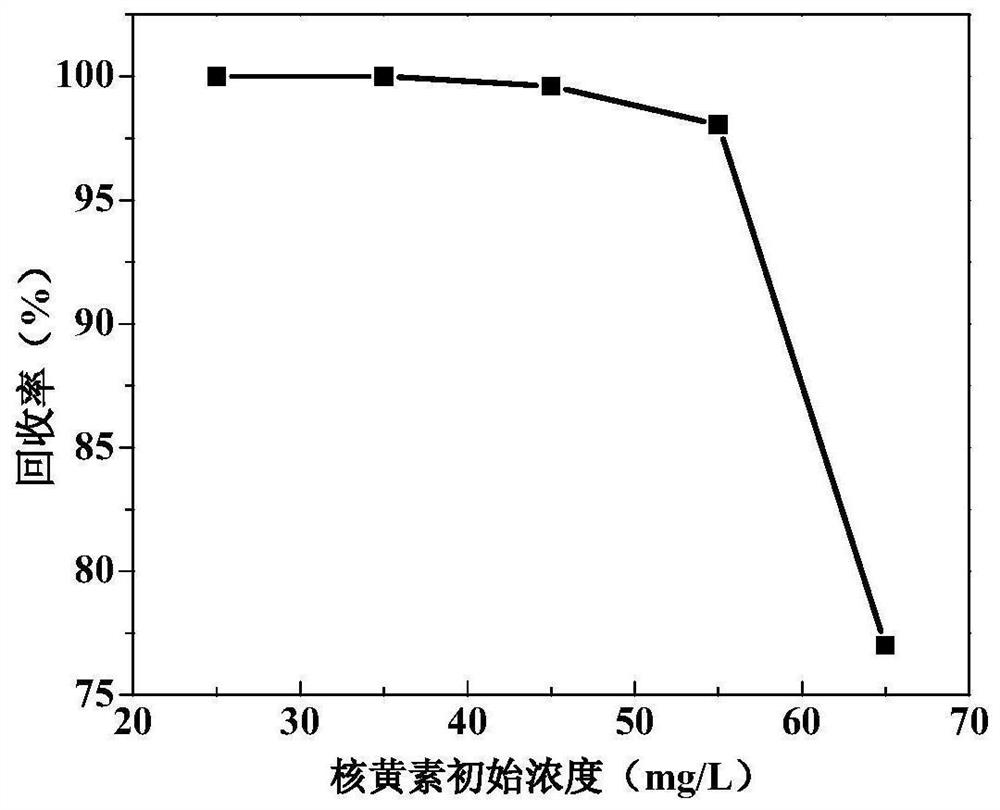

[0023] Weigh 5 mg of cyanobacteria biochar and put it into 50 mL of riboflavin solution with a concentration of 65 mg / L, control the temperature of the constant temperature shaker at 25 ° C, the speed of 150 rpm, react for 4 h, centrifuge (6000 rpm, 5 min) to obtain the supernatant, and use a spectrophotometer to detect the reaction. The concentration of riboflavin in the solution was calculated and the recovery rate of riboflavin was 77.0%.

specific Embodiment 2

[0025] The prepared cyanobacteria biochar material is used to recover the valuable component riboflavin in the solution, and the specific steps are as follows:

[0026] Weigh 5 mg of cyanobacteria biochar and put it into 50 mL of riboflavin solution with a concentration of 55 mg / L, control the temperature of the constant temperature shaker at 25 ° C, the speed of 150 rpm, react for 4 h, centrifuge (6000 rpm, 5 min) to obtain the supernatant, and use a spectrophotometer to detect the reaction. The concentration of riboflavin in the solution was calculated and the recovery rate of riboflavin was 98.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com