3D printed zirconium oxide-based false tooth material and preparation method thereof

A zirconia-based, 3D printing technology, applied in the field of medical devices, can solve the problems of insufficient quality of denture materials, uneven overall quality of dentures, dark denture color, etc., to achieve high promotion and use benefits, stable processing quality, and color retention Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

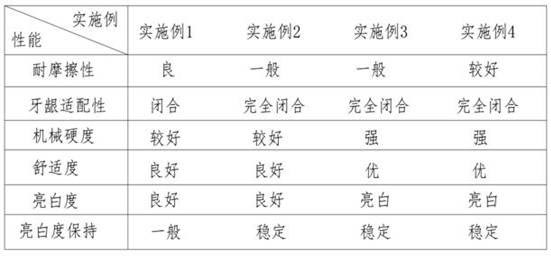

Embodiment 1

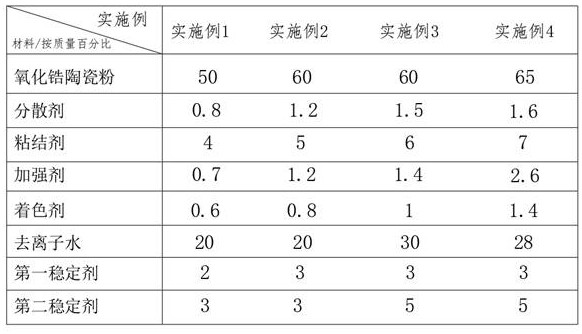

[0037] A 3D printing zirconia-based denture material, including the following ingredients (by mass percentage): 50 parts of zirconia ceramic powder, 0.8 parts of dispersing agent, 4 parts of binder, 0.7 parts of strengthening agent, 0.6 parts of coloring agent, deionized water 20 parts, 2 parts of the first stabilizer, 3 parts of the second stabilizer.

[0038] Wherein, dispersant is polyvinyl alcohol;

[0039] The binder is polylactic acid;

[0040] The strengthening agent is boron carbide;

[0041] The coloring agent is palladium oxide;

[0042] The first stabilizer is magnesium oxide;

[0043] The second stabilizer is polyethylene terephthalate.

[0044] A method for preparing a 3D printed zirconia-based denture material, comprising the following steps:

[0045] A: Preparation of the base material. Put the zirconia ceramic powder into a ball mill and grind it into a fine powder. After the ground zirconia ceramic powder is sieved, the denture base material is prepared. ...

Embodiment 2

[0052] A 3D printing zirconia-based denture material, including the following ingredients (by mass percentage): 60 parts of zirconia ceramic powder, 1.2 parts of dispersing agent, 5 parts of binder, 1.2 parts of strengthening agent, 0.8 parts of coloring agent, deionized water 20 parts, 3 parts of the first stabilizer, 3 parts of the second stabilizer.

[0053] Wherein, dispersant is polyvinyl alcohol;

[0054] The binder is silk fibroin;

[0055] The strengthening agent is silicon nitride;

[0056] The coloring agent is palladium oxide;

[0057] The first stabilizer is magnesium oxide;

[0058] The second stabilizer is polyethylene terephthalate.

[0059] A method for preparing a 3D printed zirconia-based denture material, comprising the following steps:

[0060] A: Preparation of the base material. Put the zirconia ceramic powder into a ball mill and grind it into a fine powder. After the ground zirconia ceramic powder is sieved, the denture base material is prepared. T...

Embodiment 3

[0067] A 3D printing zirconia-based denture material, including the following ingredients (by mass percentage): 60 parts of zirconia ceramic powder, 1.5 parts of dispersing agent, 6 parts of binder, 1.4 parts of strengthening agent, 1 part of coloring agent, deionized water 30 parts, 3 parts of the first stabilizer, 5 parts of the second stabilizer.

[0068] Wherein, dispersant is polyvinyl alcohol;

[0069] The binder is silk fibroin;

[0070] The strengthening agent is titanium carbide;

[0071] The coloring agent is palladium oxide;

[0072] The first stabilizer is magnesium oxide;

[0073] The second stabilizer is polyethylene terephthalate.

[0074] A method for preparing a 3D printed zirconia-based denture material, comprising the following steps:

[0075] A: Preparation of the base material. Put the zirconia ceramic powder into a ball mill and grind it into a fine powder. After the ground zirconia ceramic powder is sieved, the denture base material is prepared. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com