Separation and purification technology of pineapple peel flavone and flavone

A technology for separation, purification and peel, which is applied to the separation and purification method of flavonoids from pineapple peel and the field of flavonoids, and can solve the problems of low purity of flavonoids, affecting efficacy and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

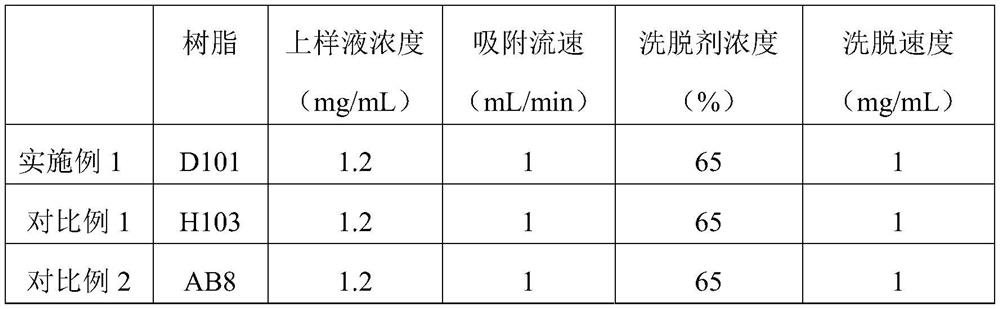

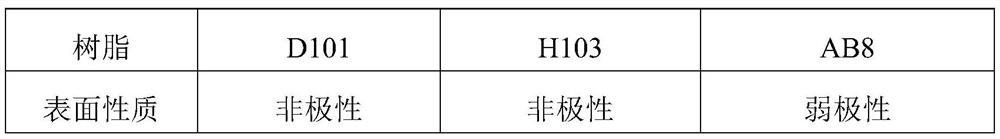

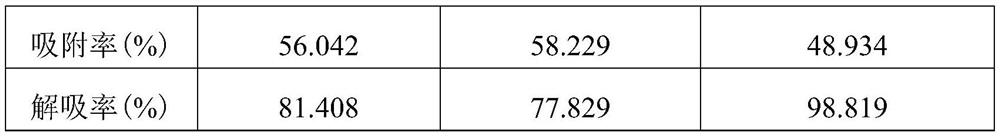

Examples

Embodiment 1

[0027] A method for separating and purifying flavonoids from pineapple peel, comprising the steps of:

[0028] Step 1, preparation of pineapple peel powder

[0029] Wash the pineapple peel and put it into an oven for drying treatment at 60°C to 70°C. Take out the dried pineapple peel and crush it with a grinder, put the peel powder into a clean sealed bag, and store it in the refrigerator.

[0030] Step 2, the preparation of pineapple peel flavonoid crude extract

[0031] Accurately weigh a certain amount of dried pineapple peel powder in a 1000mL beaker, and degrease with petroleum ether with a solid-to-liquid ratio of 1:2 (w / v). After the petroleum ether is evaporated to dryness, the degreased pineapple peel is obtained. Solid-to-liquid ratio 1:30 (w / v) Soak in ethanol with a volume fraction of 70% for 4 to 6 hours, stir evenly, transfer to a 2000mL two-necked flat-bottomed flask, then extract under microwave power 600W for 10 minutes, suction filter while hot, transfer to...

Embodiment 2

[0037] Step 1, preparation of pineapple peel powder

[0038] Wash the pineapple peel and put it into an oven for drying treatment at 60°C to 70°C. Take out the dried pineapple peel and crush it with a grinder, put the peel powder into a clean sealed bag, and store it in the refrigerator.

[0039] Step 2, the preparation of pineapple peel flavonoid crude extract

[0040] Accurately weigh a certain amount of dried pineapple peel powder in a 1000mL beaker, and degrease with petroleum ether with a solid-to-liquid ratio of 1:2 (w / v). After the petroleum ether is evaporated to dryness, the degreased pineapple peel is obtained. Solid-to-liquid ratio 1:30 (w / v) Soak in ethanol with a volume fraction of 70% for 4 to 6 hours, stir evenly, transfer to a 2000mL two-necked flat-bottomed flask, then extract under microwave power 600w for 10min, suction filter while hot, transfer to Evaporate and concentrate in a rotary evaporator until there is no ethanol, and store for future use.

[00...

Embodiment 3

[0046] Step 1, preparation of pineapple peel powder

[0047] Wash the pineapple peel and put it into an oven for drying treatment at 60°C to 70°C. Take out the dried pineapple peel and crush it with a grinder, put the peel powder into a clean sealed bag, and store it in the refrigerator.

[0048] Step 2, the preparation of pineapple peel flavonoid crude extract

[0049] Accurately weigh a certain amount of dried pineapple peel powder in a 1000mL beaker, and degrease with petroleum ether with a solid-to-liquid ratio of 1:2 (w / v). After the petroleum ether is evaporated to dryness, the degreased pineapple peel is obtained. Solid-to-liquid ratio 1:30 (w / v) Soak in ethanol with a volume fraction of 70% for 4 to 6 hours, stir evenly, transfer to a 2000mL two-necked flat-bottomed flask, then extract under microwave power 600w for 10min, suction filter while hot, transfer to Evaporate and concentrate in a rotary evaporator until there is no ethanol, and store for future use.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com