Production method of feed-grade calcium hydrogen phosphate

A technology of calcium hydrogen phosphate and its production method, which is applied in the fields of chemistry and metallurgy, can solve the problems of low water-soluble content, low nutritional content, long process flow, etc., achieve high water-soluble content, high phosphorus content, and improve product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

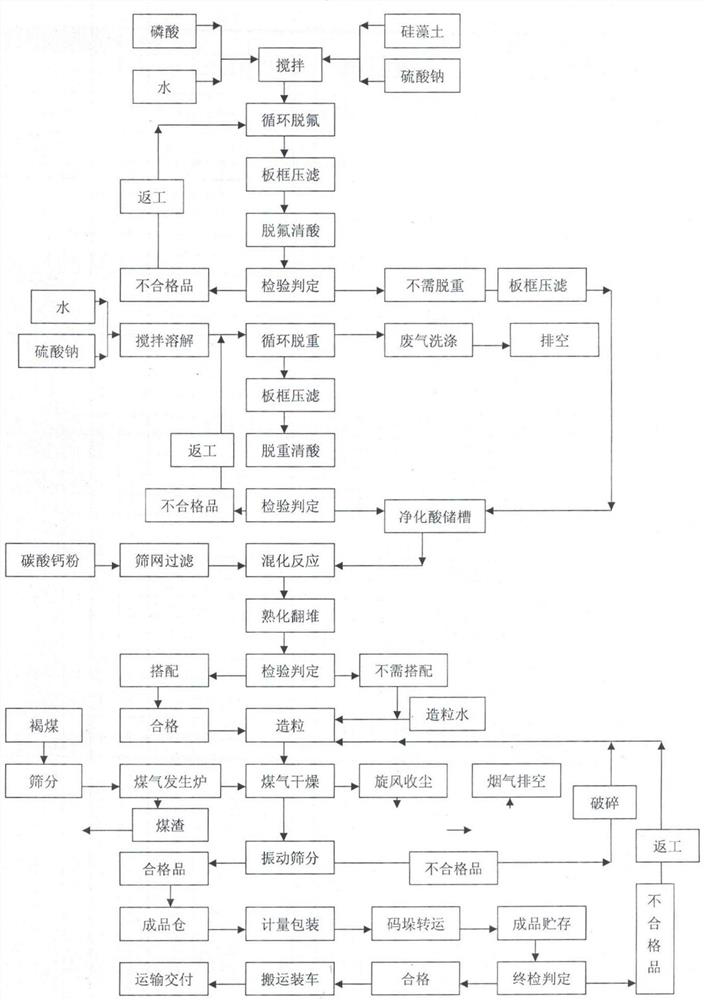

[0023] Attached below figure 1 The present invention is further described.

[0024] A kind of feed grade calcium hydrogen phosphate production method is characterized in that comprising the following steps:

[0025] Step 1: Add phosphoric acid, water, diatomaceous earth, and sodium sulfate in proportion to a closed mixer for stirring. During the stirring process, the process of circulating fluorine is used to remove the fluorine generated by the reaction to obtain a mixture;

[0026] Step 2: filter the above-mentioned mixture with a plate and frame filter press to remove the liquid, and then add it to the purified acid storage tank;

[0027] Step 3: After stirring and dissolving sodium sulfate and water, the weight is removed by circulation, and then the plate and frame filter is used to remove the weight and clear the acid before use;

[0028] Step 4: adding the material in the purified acid storage tank in step 2 and the sodium sulfate material after de-acidification in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com