Sludge or oily sludge drying and incineration treatment circulating system and treatment method

A circulating system and drying treatment technology, applied in water/sludge/sewage treatment, sludge treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high processing cost, high operating cost and high processing cost , to achieve the effect of solving the problem of secondary pollution, solving public nuisance and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

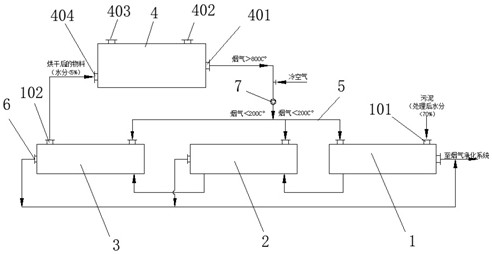

[0029] Such as figure 1 As shown, this embodiment includes three dryers connected to each other, which are respectively the first dryer 1, the second dryer 2 and the third dryer, and the outlet of the first dryer 1 is connected to the second dryer The feed port 101 of the second dryer is connected, the discharge port of the second dryer 2 is connected with the feed port of the third dryer, and the discharge port 102 of the third dryer 3 is connected with the low calorific value fuel incinerator The feed port 404 is connected, and the low calorific value fuel incinerator 4 is provided with an exhaust port 401, and the exhaust port 401 is respectively connected to the air inlet of each dryer through the supplementary air duct 5 provided with the cooling air inlet. Each dryer is provided with a waste gas outlet 6, the low calorific value incinerator 4 is provided with an ash outlet 402 and an air inlet 403, and the supplementary air pipeline 5 is also provided with a cooling air ...

Embodiment 2

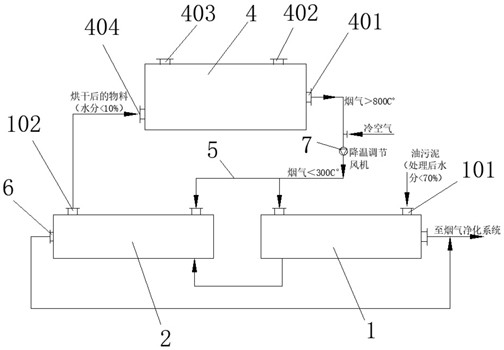

[0040] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that two dryers connected to each other are provided in this embodiment.

[0041] All the other are with embodiment 1.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is that the low calorific value incinerator 4 in this embodiment is a circulating fluidized bed boiler that purely burns 600-2000 cal / kg low calorific value fuel, and the upper part of the circulating fluidized bed boiler is equipped with steam pot.

[0044] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com