Preparation method and application of alanine metal chelate

A metal chelate and alanine technology, applied in the preparation of organic compounds, cyanide reaction preparation, 1/11 group organic compounds without C-metal bonds, etc., can solve the low utilization rate of amino acids and metal salts , increase production costs, waste resources and other issues, to achieve the effect of shortening the production cycle, improving quality, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Preparation of Alanine Chelated Zinc

[0041] (1) 267.3g of alanine was dissolved in 3L of water to obtain alanine solution;

[0042] (2) according to alanine: the mol ratio of zinc chloride is 2:1, in the alanine solution that makes, add zinc chloride solution, under stirring condition, add sodium hydroxide solution, adjust reaction solution pH6.0 Afterwards, it was placed in a water bath at 80°C for ultrasonic treatment with an ultrasonic power of 100w and an ultrasonic time of 1h to obtain a reaction solution;

[0043] (3) Vacuum-concentrate the reaction solution (-0.085MPa—0.095MPa) to 500mL in a water bath at 60-70°C;

[0044] (4) After adding 1.5L of absolute ethanol to the concentrated solution prepared in step (3), place it in a water bath at 70°C for 1 hour, and then carry out vacuum concentration (-0.085MPa—-0.095MPa) at 70°C to nothing Water, a large number of white crystals are precipitated;

[0045] (5) Add 3.0-4.0L of absolute ethanol to the ...

Embodiment 2

[0047] Example 2 Preparation of alanine chelated magnesium

[0048] (1) Dissolve 300g of alanine in 3.3L of water to prepare an alanine solution;

[0049] (2) according to alanine: the mol ratio of magnesium chloride is 2:1, in the alanine solution that makes, add magnesium chloride solution, under stirring condition, add sodium hydroxide solution, after adjusting reaction solution pH6.0, it is mixed with Place in a water bath at 90°C for ultrasonic treatment, with an ultrasonic power of 100w and an ultrasonic time of 1h, to obtain a reaction solution;

[0050] (3)-(5) are the same as embodiment 1.

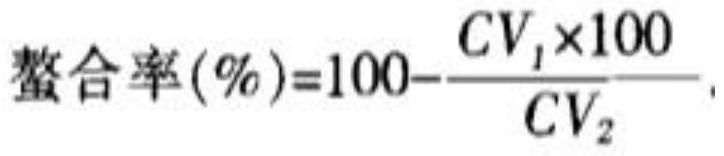

[0051] Using the detection method of the present invention to detect, the chelation rate is 93%.

Embodiment 3

[0052] Example 3 Preparation of alanine chelated copper

[0053](1) take by weighing the alanine of 267.3g, be dissolved in 3L water, make alanine solution;

[0054] (2) According to alanine: the mol ratio of copper chloride is 2:1, add copper chloride solution in the prepared alanine solution, stir, dissolve, add sodium hydroxide solution in the prepared reaction solution , adjust the pH of the reaction solution to 5.5, place it in a water bath at 80°C for ultrasonic treatment, the ultrasonic power is 100w, and the ultrasonic time is 1h, to obtain the reaction solution;

[0055] (3)-(5) are the same as embodiment 1.

[0056] Using the detection method of the present invention to detect, the chelation rate is 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com