Conductive non-woven fabric adhesive tape and manufacturing method thereof

A manufacturing method and non-woven technology, which are used in conductive adhesives, textiles, papermaking, adhesives, etc., can solve the problems of unenvironmental protection, high cost, and unfriendly production process, and achieve continuous production and mass production. The effect of cost reduction and superior product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

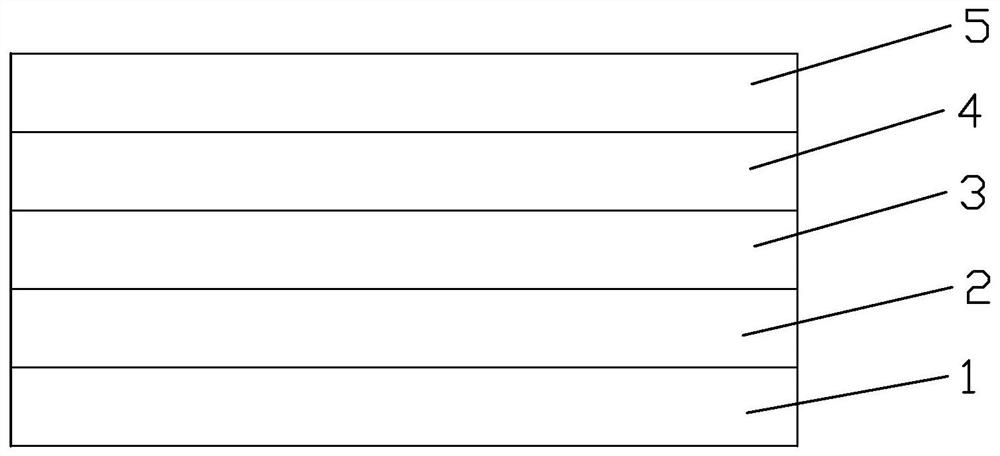

[0033] See figure 1 , the conductive non-woven tape of the present invention is a single-sided conductive non-woven tape, comprising a substrate layer 1, an evaporation layer 2, a cold-sprayed metal deposition layer 3, a heterogeneous conductive adhesive layer 4 and a release layer that are sequentially stacked and distributed from bottom to top. Type film layer 5. Wherein the substrate layer 1 is made of a non-woven fabric with a thickness of 10um to 100um as the substrate, which can be polyester, polypropylene, nylon, spandex or acrylic fiber, the harder the better. Evaporation layer 2 is a conductive layer of metal such as silver, copper or nickel plated on one side of substrate layer 1 by vacuum magnetron sputtering evaporation method, and the thickness of the evaporation layer 2 is 100nm (nanometer) to 1um ( microns). The cold-sprayed metal deposition layer 3 is a continuous conductive cold-sprayed metal deposition layer 3 sprayed and deposited on the evaporated layer 2...

Embodiment 2)

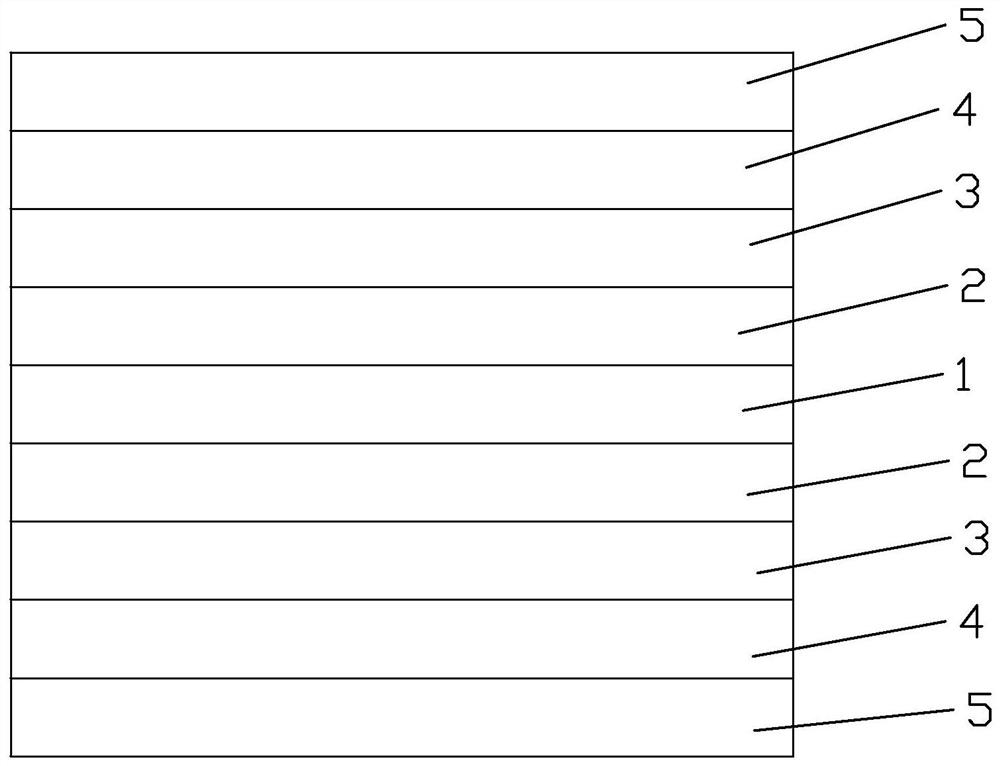

[0035] See figure 2 , the conductive non-woven tape of the present invention is a double-sided conductive non-woven tape, including a substrate layer 1 and an evaporation layer 2 and a cold-sprayed metal deposition layer 3 that are symmetrically stacked up and down with the substrate layer 1 as the center layer. , Heterogeneous conductive adhesive layer 4 and release film layer 5. Wherein the substrate layer 1 is made of a non-woven fabric with a thickness of 10um to 100um as the substrate, which can be polyester, polypropylene, nylon, spandex or acrylic fiber, the harder the better. Evaporation layer 2 is a conductive layer of metal such as silver, copper or nickel plated on one side of substrate layer 1 by vacuum magnetron sputtering evaporation method, and the thickness of the evaporation layer 2 is 100nm (nanometer) to 1um ( microns). The cold-sprayed metal deposition layer 3 is a continuous conductive cold-sprayed metal deposition layer 3 sprayed and deposited on the e...

Embodiment 3)

[0037] The manufacture method of the conductive nonwoven tape obtained by embodiment 1 or 2 may further comprise the steps:

[0038] ①Choose a non-woven fabric with a thickness of 10um to 100um as the substrate layer 1. The pores between the non-woven fabrics must be less than 0.3mm, preferably less than 0.1mm, and the denser the better. If the pores are too large, the pre-evaporated vapor deposition layer 2 will be broken down during cold spraying, and the cold spraying process cannot form a continuous and dense cold sprayed metal deposition layer 3 . The non-woven material can be polyester, polypropylene, nylon, spandex, acrylic, etc., the harder the better.

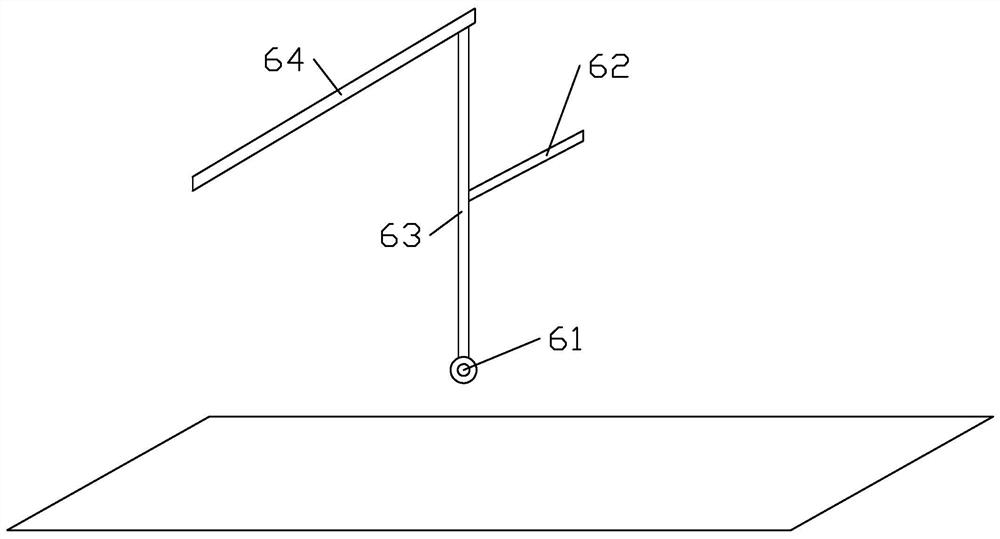

[0039] ②Using the vacuum magnetron sputtering evaporation method, one or both sides of the substrate layer 1 are coated with a metal conductive layer such as silver, copper or nickel, that is, the evaporation layer 2, and the thickness of the evaporation layer 2 is nanometer , usually around 100nm (nanometer). Its fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com