Method for increasing roughness on semiconductor surface

A semiconductor and roughness technology, which is applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of low etching selectivity, damage to semiconductor components, and roughness that is difficult to achieve roughness, so as to avoid the formation of excessive etching , slow down the etching speed, increase the effect of roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

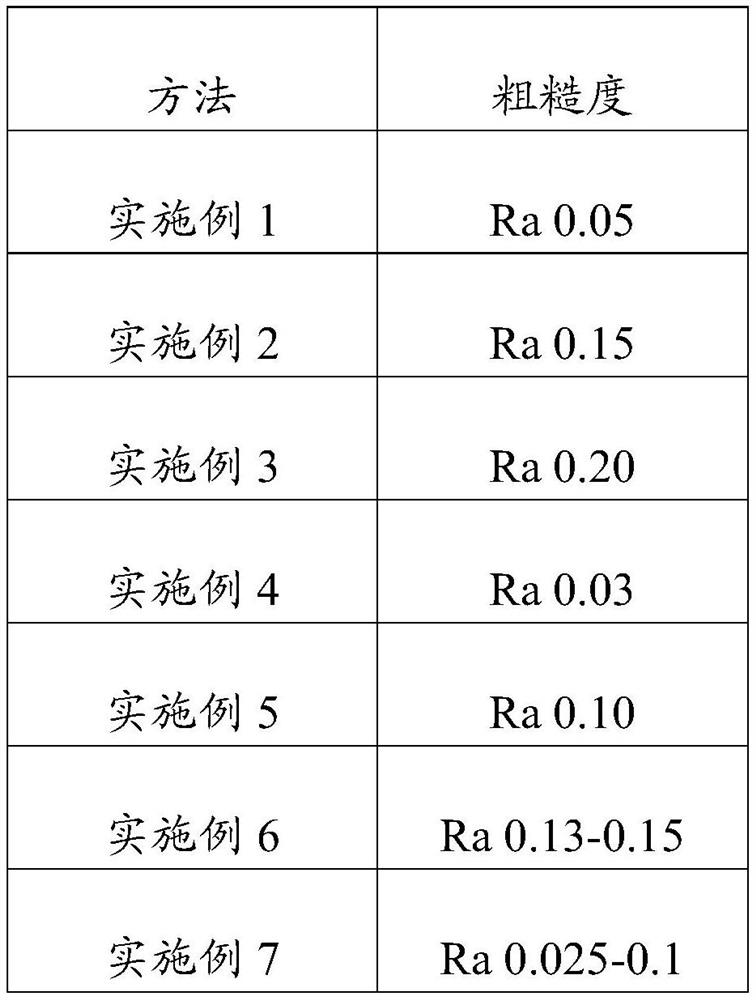

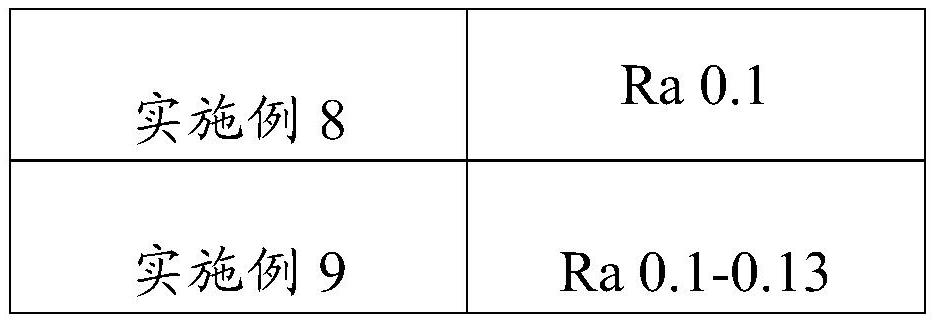

Embodiment 1

[0021] As a method for increasing roughness on a semiconductor surface according to an embodiment of the present invention, the method includes the following steps:

[0022] (1) Provide a semiconductor and determine the area where the roughness of the semiconductor surface is to be increased, denoted as area A, and the thickness of the photoresist is 10 μm;

[0023] (2) use photoresist to shield the semiconductor surface except other parts of area A;

[0024] (3) Load the semiconductor processed in step (2) into the semiconductor processing chamber, and form a vacuum in the processing chamber with a vacuum degree of 0.000006 Toor, and introduce a mixture of inert gas and hydrocarbon gas into the processing chamber to maintain the processing The chamber vacuum is 0.004 Toor, and the mixed gas is ionized to form an ion beam for etching; the inert gas is argon, the hydrocarbon gas is ethylene, and the volume ratio of argon in the mixed gas is 85%. The etching time is 30-45 minut...

Embodiment 2

[0027] As a method for increasing roughness on the surface of a semiconductor according to an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the volume ratio of argon in the mixed gas is 90%.

Embodiment 3

[0029] As a method for increasing roughness on a semiconductor surface in an embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the volume ratio of argon in the mixed gas is 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com