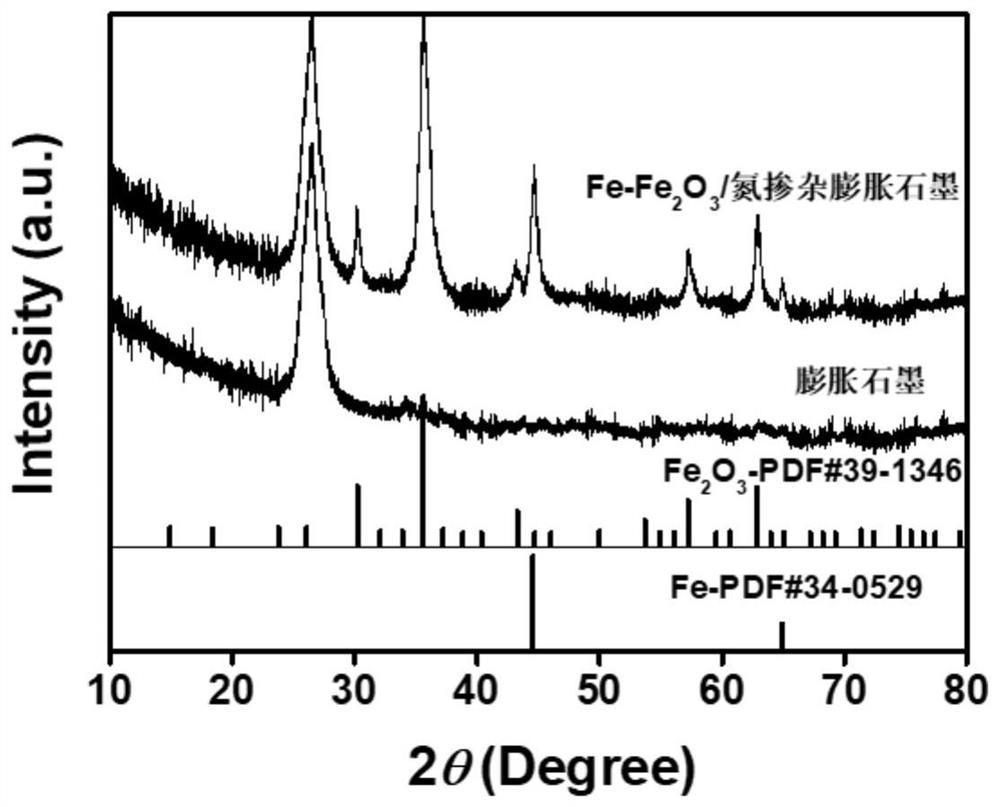

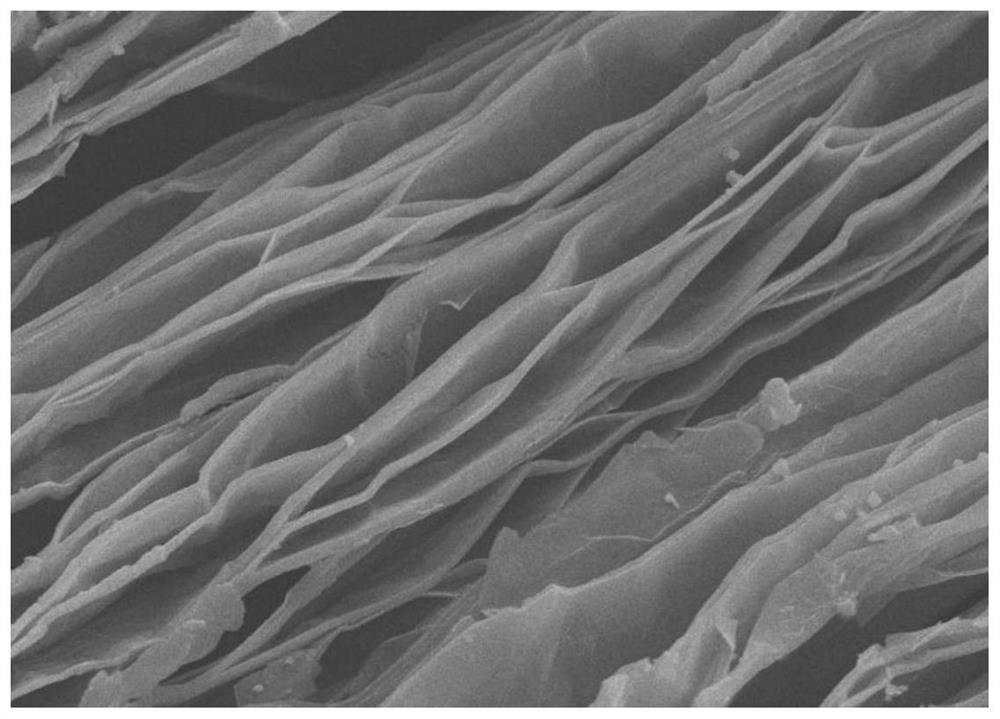

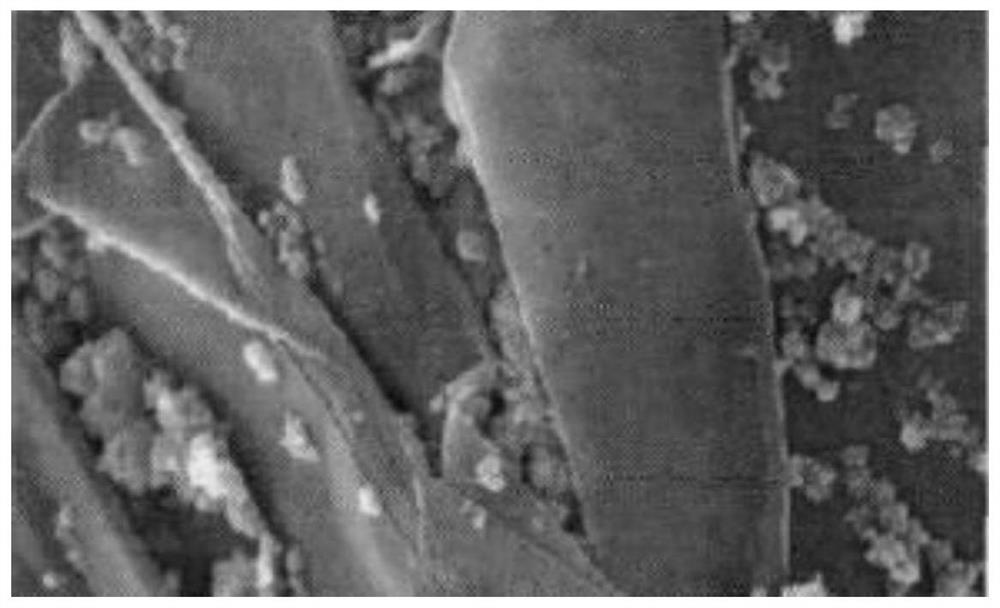

Fe-Fe2O3/nitrogen-doped expanded graphite composite material for grease adsorption

A technology of fe-fe2o3 and expanded graphite, which is applied in the direction of fat oil/fat refining, fat production, alkali metal compounds, etc., can solve the problems of high processing cost and narrow application range, and achieve high specific surface area, cost saving and strong adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of expandable graphite: uniformly mix 3g of natural flake graphite and 0.75g of potassium permanganate, then add 15ml of concentrated nitric acid, stir the mixture at 40°C for 60min, and wash the product with deionized water after the reaction is complete Filter with suction, adjust the pH to neutral, and then dry in an oven at 60°C for 12 hours to obtain expandable graphite.

[0027] (2) Preparation of hydrated iron oxide / expandable graphite composite material: 0.05mol Fe(NO 3 ) 2 ·6H 2 The mixture of O and 0.05mol citric acid was dissolved in 60ml deionized water at room temperature, and the expandable graphite obtained in step (1) was added to the mixed solution after it was completely dissolved, and it was ultrasonically dispersed for 30min, and then added dropwise to the mixed solution under agitation. Add 4mol / l NaOH solution, and when the pH value reaches 13, dilute the mixed solution to 100ml. Air was introduced into the mixed solution with an...

Embodiment 2

[0030] (1) Preparation of expandable graphite: uniformly mix 3g of natural flake graphite and 0.5g of potassium permanganate, then add 18ml of concentrated nitric acid, stir the mixture at 60°C for 80min, and wash the product with deionized water after the reaction is complete Filter with suction, adjust the pH to neutral, and then dry in an oven at 60°C for 12 hours to obtain expandable graphite.

[0031] (2) Preparation of hydrated iron oxide / expanded graphite composite material: 0.04mol Fe(NO 3 ) 2 ·6H 2 The mixture of O and 0.05mol citric acid was dissolved in 60ml deionized water at room temperature, and the expandable graphite obtained in step (1) was added to the mixed solution after it was completely dissolved, and it was ultrasonically dispersed for 30min, and then added dropwise to the mixed solution under agitation. Add 4mol / l NaOH solution, and when the pH value reaches 13, dilute the mixed solution to 100ml. Air was introduced into the mixed solution with an ox...

Embodiment 3

[0034] (1) Preparation of expandable graphite: Mix 3g of natural flake graphite and 1.0g of potassium permanganate evenly, then add 21ml of concentrated nitric acid, stir the mixture at 60°C for 100min, and wash the product with deionized water after the reaction is complete Filter with suction, adjust the pH to neutral, and then dry in an oven at 60°C for 12 hours to obtain expandable graphite.

[0035] (2) Preparation of hydrated iron oxide / expandable graphite composite material: 0.03mol Fe(NO 3 ) 2 ·6H 2 The mixture of O and 0.04mol citric acid was dissolved in 60ml deionized water at room temperature, and the expandable graphite obtained in step (1) was added to the mixed solution after the dissolution was completed and ultrasonically dispersed for 30min, and then added dropwise to the mixed solution under agitation. Add 4mol / l NaOH solution, and when the pH value reaches 13, dilute the mixed solution to 100ml. Air was introduced into the mixed solution with an oxygen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com