Preparation process of high-stability water-based paint

A water-based coating, high-stability technology, applied in coating, separation method, grain treatment, etc., can solve the problems of affecting the processing and production efficiency of water-based coatings, reducing the efficiency of grinding of coating raw materials, affecting the use of water-based coatings, etc. Transmission and filtering, safe and convenient use, and the effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

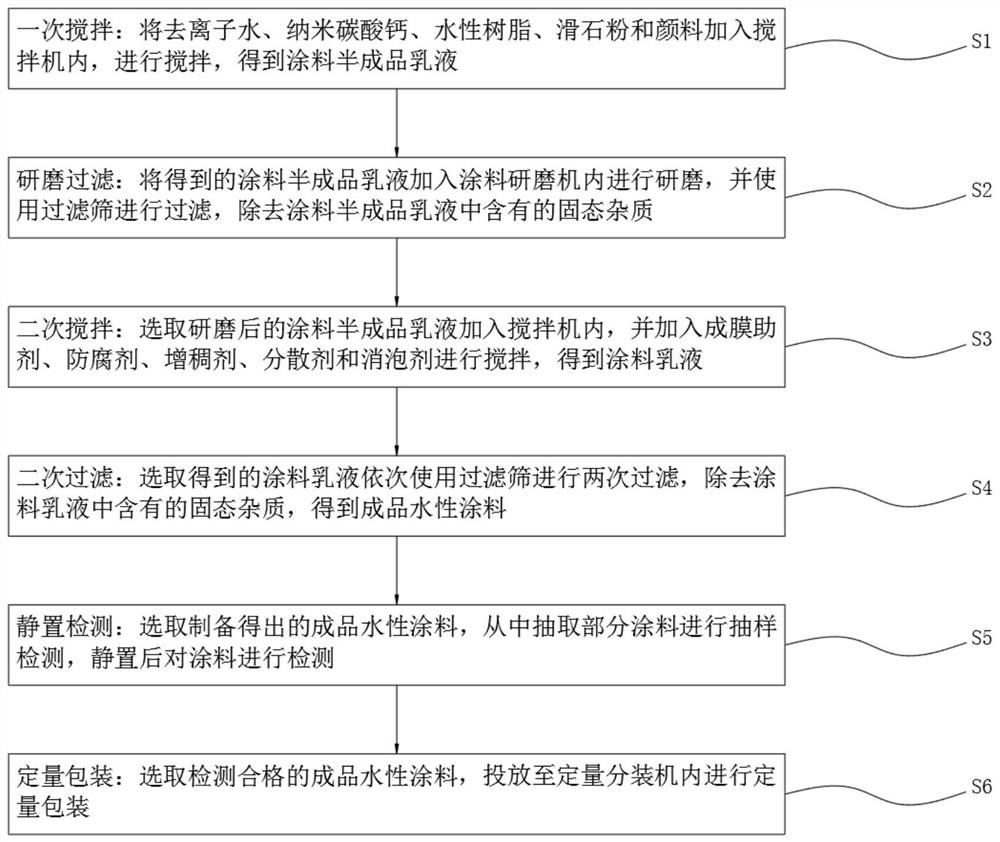

[0045] Such as figure 1 Shown, the present invention provides technical scheme, a kind of preparation technology of high-stability water-based coating, high-stability water-based coating is made up of following components by weight:

[0046] 100 parts by weight of water-based resin, 9 parts by weight of nano-calcium carbonate, 6 parts by weight of film-forming aid, 1 part by weight of preservative, 10 parts by weight of talcum powder, 17 parts by weight of pigment, 0.8 parts by weight of thickener, and 0.4 parts by weight of dispersant , 0.4 parts by weight of an antifoaming agent and 50 parts by weight of deionized water.

[0047] According to the above technical features, the film-forming aid is specifically dodecyl alcohol ester, the preservative is specifically isothiazolinone, the thickener is specifically polyacrylic acid thickener, and the dispersant is specifically polyacrylic acid ammonium salt.

[0048] According to above-mentioned technical feature, a kind of prepa...

Embodiment 2

[0057] Such as figure 1 Shown, the present invention provides technical scheme, a kind of preparation technology of high-stability water-based coating, high-stability water-based coating is made up of following components by weight:

[0058] 80 parts by weight of water-based resin, 7 parts by weight of nano-calcium carbonate, 3 parts by weight of film-forming aid, 0.5 parts by weight of preservative, 8 parts by weight of talcum powder, 10 parts by weight of pigment, 0.4 parts by weight of thickener, and 0.2 parts by weight of dispersant , 0.1 parts by weight of an antifoaming agent and 40 parts by weight of deionized water.

[0059] According to the above technical features, the film-forming aid is specifically ethylene glycol, the preservative is specifically a nitrogen-sulfur cyclic compound, the thickener is specifically a polyacrylic acid thickener, and the dispersant is specifically a polyacrylic acid ammonium salt.

[0060] According to above-mentioned technical feature...

Embodiment 3

[0069] Such as figure 1 Shown, the present invention provides technical scheme, a kind of preparation technology of high-stability water-based coating, high-stability water-based coating is made up of following components by weight:

[0070] 120 parts by weight of water-based resin, 12 parts by weight of nano-calcium carbonate, 9 parts by weight of film-forming aid, 1.5 parts by weight of preservative, 12 parts by weight of talc, 24 parts by weight of pigment, 1.2 parts by weight of thickener, and 0.6 parts by weight of dispersant , 0.6 parts by weight of an antifoaming agent and 60 parts by weight of deionized water.

[0071] According to the above technical features, the film-forming aid is specifically dodecyl alcohol ester, the preservative is specifically isothiazolinone, the thickener is specifically high molecular weight hydroxyethyl cellulose, and the dispersant is specifically polycarboxylate sodium salt.

[0072] According to above-mentioned technical feature, a kin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com