A kind of backing paper and its preparation method

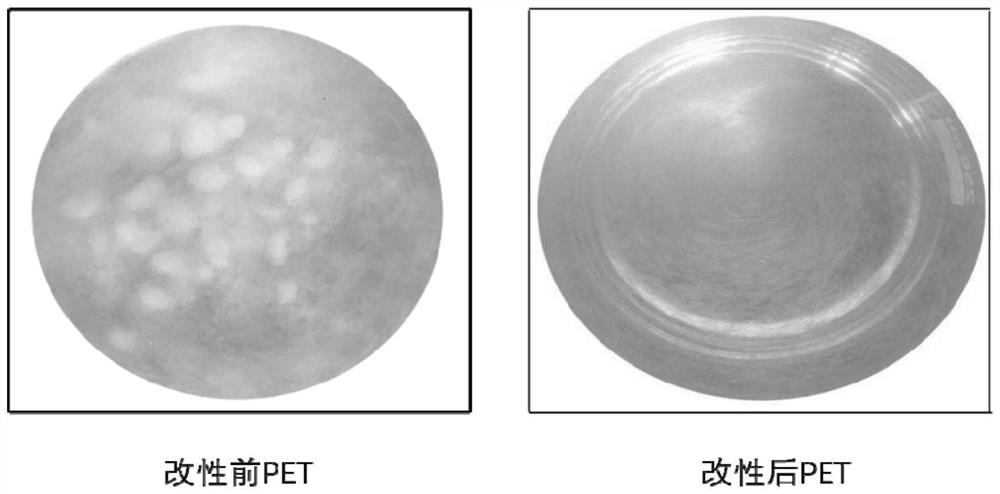

A technology of liner paper and polyester fiber, which is applied in the field of liner paper and its preparation, can solve the problems of unreachable and unsolved liner paper wet strength, air permeability, etc., and achieves improved wet strength, good economic benefits, and simplification. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A preparation method of hydrophilic polyester fiber for papermaking, comprising the steps of:

[0065] (1) Add 0.6057g of Tris in 50mL of ionized water, configure a Tris solution with a concentration of 0.1mol / L, add an appropriate amount of hydrochloric acid to adjust the pH to 8.5 as a Tris-HCl buffer solution;

[0066] (2) 1.5 parts of polyester PET fibers were ultrasonically cleaned three times in 5 parts of acetone solution, each time for 30 minutes, then washed three times with deionized water, and then dried under vacuum for 12 hours to obtain pretreated PET fibers;

[0067] (3) Add 8 parts of 1.0g / L gallic acid solution and 2 parts of 0.1mol / L Tris-HCl buffer solution into the reaction vessel, stir at 200rpm at room temperature for 15min to obtain a mixed solution;

[0068] (4) Add 4 parts of 1.0 g / L ethylenediamine solution to the mixed solution in step (3), stir at 600 rpm at room temperature for 2-3 minutes and mix evenly to obtain a treatment solution;

[0...

Embodiment 2

[0072] A preparation method of hydrophilic polyester fiber for papermaking, comprising the steps of:

[0073] (1) Add 0.6057g of Tris in 50mL of ionized water, configure a Tris solution with a concentration of 0.1mol / L, add an appropriate amount of hydrochloric acid to adjust the pH to 8.5 as a Tris-HCl buffer solution;

[0074] (2) 1 part of PET fiber was ultrasonically cleaned three times in 8 parts of acetone solution, each time for 30 minutes, then washed three times with deionized water, and then dried under vacuum for 12 hours to obtain the pretreated PET fiber;

[0075] (3) Add 6 parts of 0.9g / L gallic acid solution and 2 parts of 0.3mol / L Tris-HCl buffer solution into the reaction vessel, stir at room temperature at 200rpm for 15min to obtain a mixed solution;

[0076] (4) Add 2 parts of 0.9g / L ethylenediamine solution to the mixed solution in step (3), stir at 600rpm at room temperature for 2-3min and mix evenly to obtain the treatment solution;

[0077] (5) Pre-wet ...

Embodiment 3

[0080] A preparation method of hydrophilic polyester fiber for papermaking, comprising the steps of:

[0081] (1) Add 0.6057g of Tris in 50mL of ionized water, configure a Tris solution with a concentration of 0.1mol / L, add an appropriate amount of hydrochloric acid to adjust the pH to 8.5 as a Tris-HCl buffer solution;

[0082] (2) 0.5 parts of PET fibers were ultrasonically cleaned three times in 10 parts of acetone solution, each time for 30 minutes, then washed three times with deionized water, and then dried under vacuum for 12 hours to obtain pretreated PET fibers;

[0083] (3) Add 4 parts of 0.8g / L gallic acid solution and 2 parts of 0.5mol / L Tris-HCl buffer solution into the reaction vessel, stir at 200rpm at room temperature for 15min to obtain a mixed solution;

[0084] (4) Add 1 part of 0.8g / L ethylenediamine solution to the mixed solution in step (3), stir at 600rpm at room temperature for 2-3min and mix evenly to obtain the treatment solution;

[0085] (5) Pre-we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com