Black water treatment equipment

A technology for processing equipment and black water, which is applied in the field of water treatment, can solve the problems of short-term operation, many connecting valves, complicated operation, etc., and achieve the effect of saving equipment and pipeline investment, and saving connecting pipelines and valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the invention are described in detail below, but the invention can be practiced in many different ways as defined and covered by the claims.

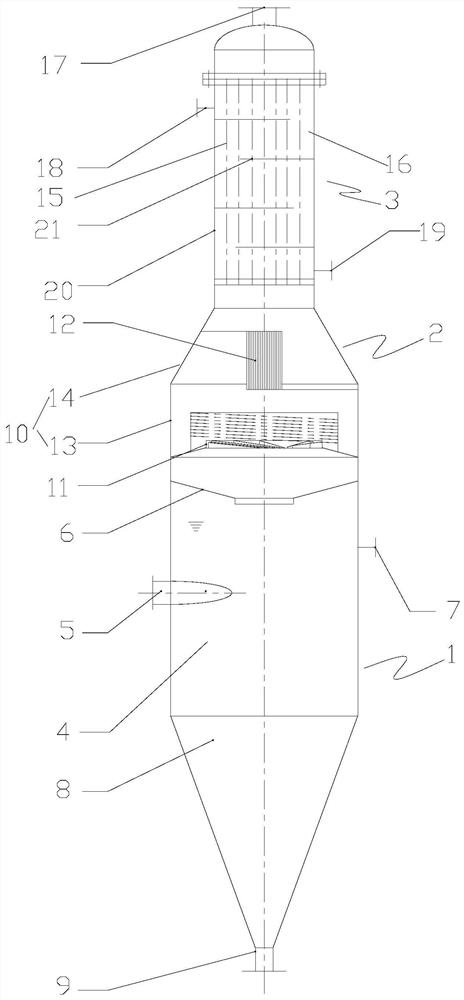

[0032] Please refer to figure 1 As shown, according to an embodiment of the present invention, the black water treatment equipment includes a lower flash section 1, a middle dust removal section 2 and an upper heat exchange section 3, the lower flash section 1 is used for flashing black water, and the middle dust removal section 2 It is connected to the top of the lower flash section 1 for gas-solid-liquid separation. The upper heat exchange section 3 is connected to the top of the middle dust removal section 2 for heat recovery. The lower flash section 1, the middle dust removal section 2 and the upper The heat exchange sections 3 communicate in sequence along the direction from bottom to top.

[0033] The black water treatment equipment in this scheme organically combines the flash tank and the heat exchanger, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com