Device and method for depositing pure DLC (diamond-like carbon) by graphite cathode arc enhanced glow discharge

A graphite cathode, glow discharge technology, applied in ion implantation plating, gaseous chemical plating, coating and other directions, can solve problems such as metal element pollution, and achieve the effect of quality assurance, low cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

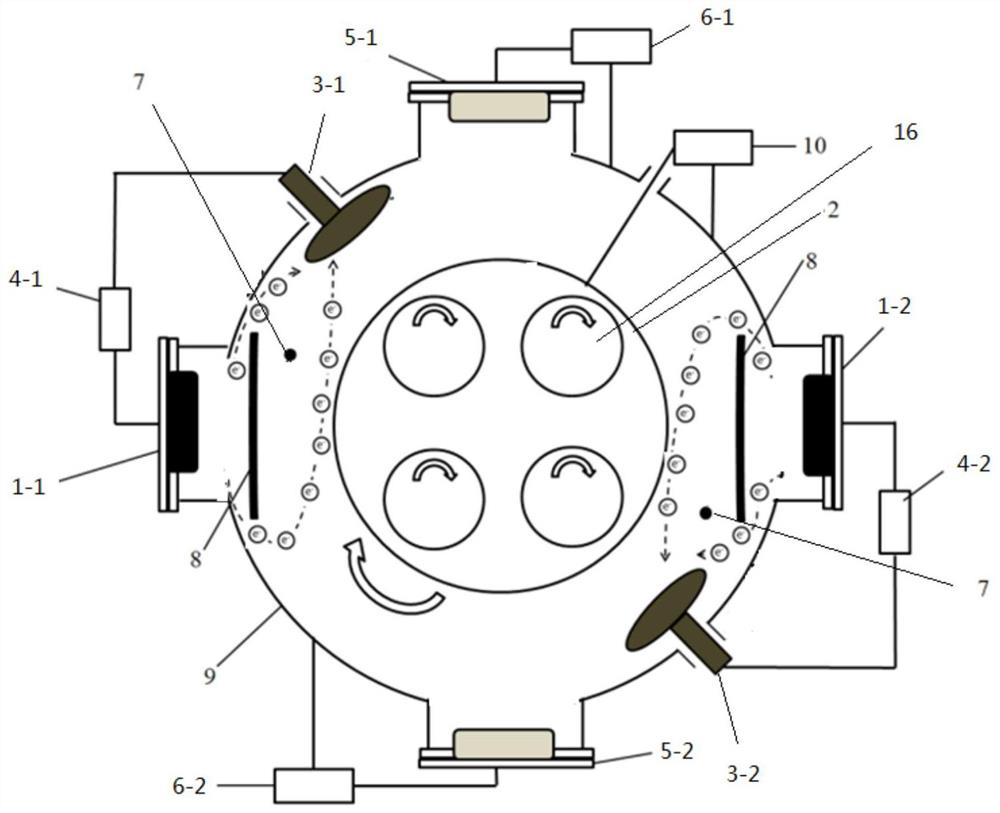

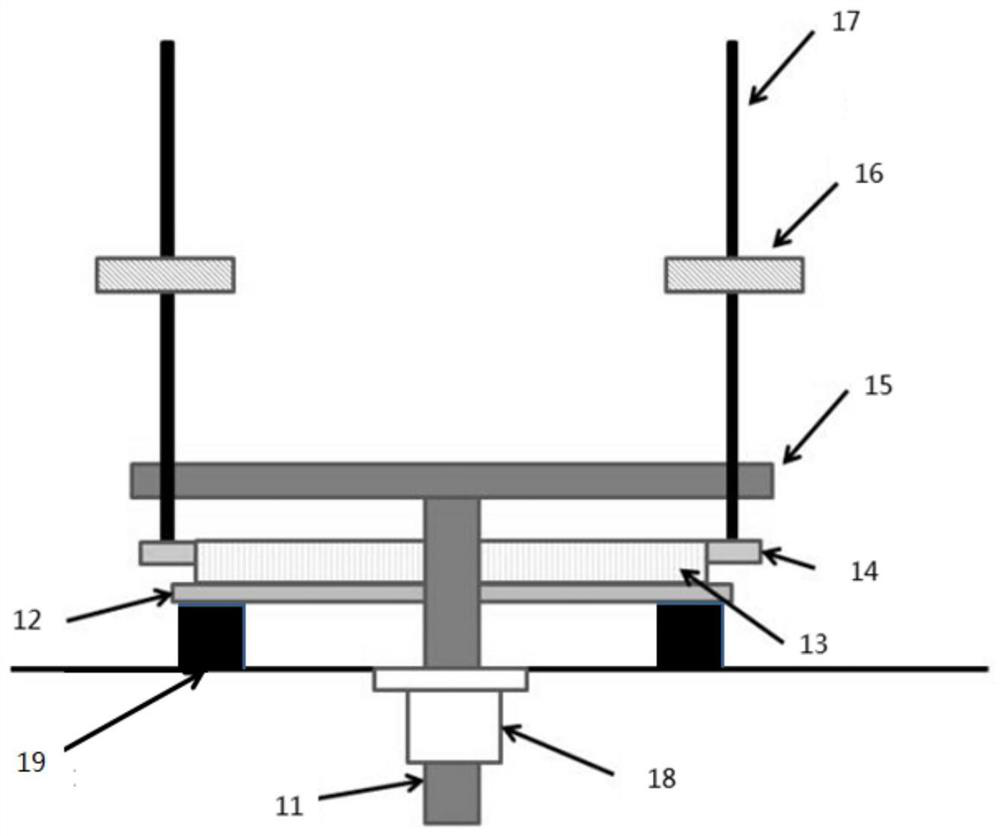

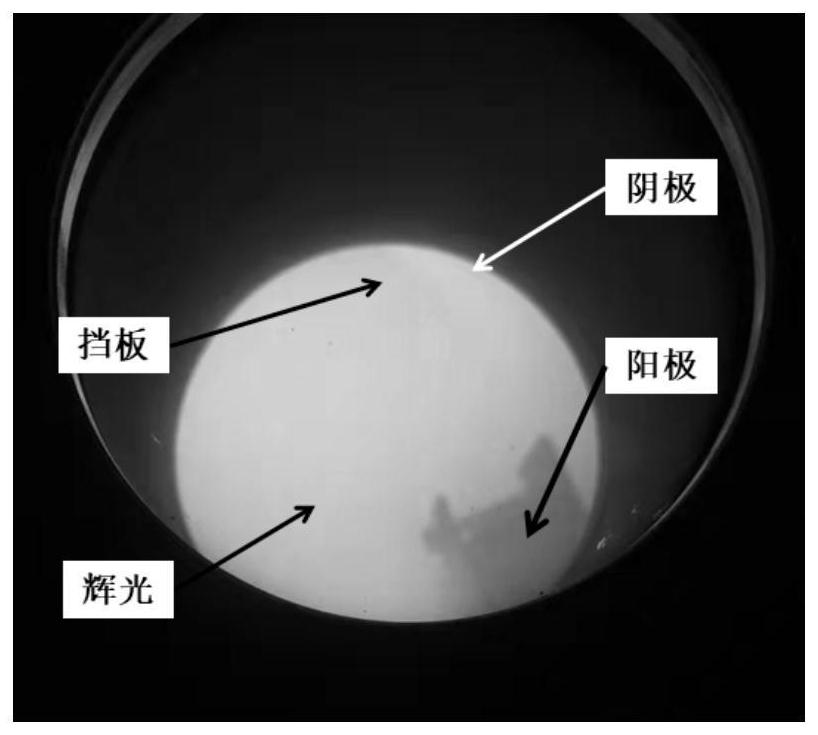

[0029]Specific Embodiment 1: In this embodiment, a device for graphite cathode arc enhanced glow discharge deposition of pure DLC includes a vacuum chamber 9, a turntable 2, a bias power supply 10, a first graphite cathode arc 1-1, and a second graphite cathode arc 1-2, first metal cathode 5-1, second metal cathode 5-2, first anode 3-1, second anode 3-2, first high pulse power supply 4-1, second high pulse power supply 4- 2. The first DC power supply 6-1 and the second DC power supply 6-2; the bottom of the vacuum chamber 9 has an air inlet 7; , four flanges are evenly arranged on the wall of the vacuum chamber 9 along the circumferential direction, and the four flanges are respectively fixedly connected to the first graphite cathode arc 1-1, the first metal cathode 5-1, and the second graphite cathode arc 1-2 and the second metal cathode 5-2; a baffle 8 is arranged between the first graphite cathode arc 1-1 and the second graphite cathode arc 1-2 and the turret 2, and the two...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the turret 2, the first graphite cathode arc 1-1, the second graphite cathode arc 1-2, the first metal cathode 5-1, the second metal The cathode 5-2, the first anode 3-1, the second anode 3-2, and the baffle 8 are all insulated from the vacuum chamber 9. Others are the same as the first embodiment.

[0032] In this embodiment, the transfer frame 2, the first graphite cathode arc 1-1, the second graphite cathode arc 1-2, the first metal cathode 5-1, the second metal cathode 5-2, the first anode 3-1, the second Both the anode 3-2 and the baffle 8 are insulated from the vacuum chamber 9 by polytetrafluoroethylene.

specific Embodiment approach 3

[0033] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the electrical connection end of the first anode 3-1 is electrically connected with the positive pole of the first high pulse power supply 4-1, and the first high pulse power supply 4-1 The negative pole of 1 is electrically connected to the electrical connection end of the first graphite cathode arc 1-1; the electrical connection end of the second anode 3-2 is electrically connected to the positive pole of the second high pulse power supply 4-2, and the second high pulse power supply 4- The negative electrode of 2 is electrically connected to the electrical connection end of the second graphite cathode arc 1-2. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com