MXene two-dimensional material as well as preparation method and application thereof

A two-dimensional material and reaction technology, applied in the field of materials, can solve problems such as long time, not environmentally friendly, and difficult to control, and achieve the effects of saving preparation processes, large specific surface area, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A preparation method of MXene two-dimensional material, comprising the following steps:

[0036] Step 1: preparing a reaction deposition solution of fluorine-containing salt and boric acid;

[0037] Step 2: placing the MXene precursor in the reaction deposition liquid in step 1 for hydrothermal reaction to obtain a suspension;

[0038] Step 3: Centrifuge the suspension in step 2, take the suspension, wash it to neutral, and dry to obtain the MXene two-dimensional material, wherein the washing can be alternately washed with deionized water and ethanol.

[0039] In the second step, ultrasonic treatment is performed while hydrothermal reaction is performed, specifically, the ultrasonic treatment time is 1-3 hours.

[0040] In the second step, the reaction temperature of the hydrothermal reaction is 90-180°C, and the reaction time is 1-12h.

[0041] In the second step, the hydrothermal reaction uses a hydrothermal reaction kettle made of polyvinyl fluoride, and the high-t...

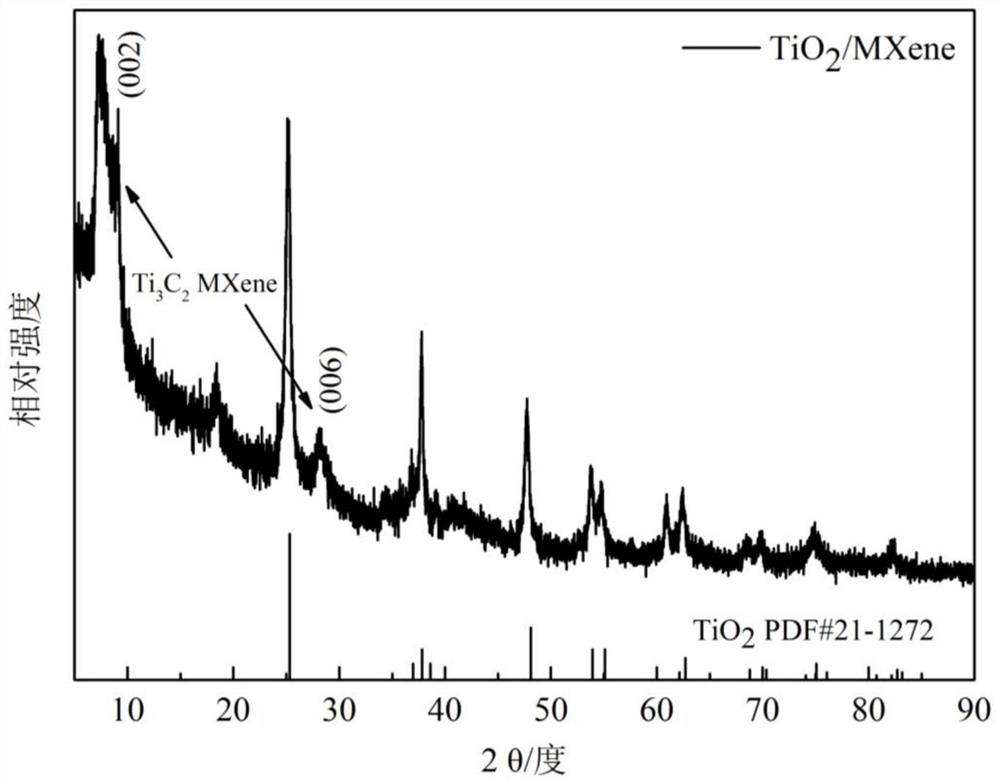

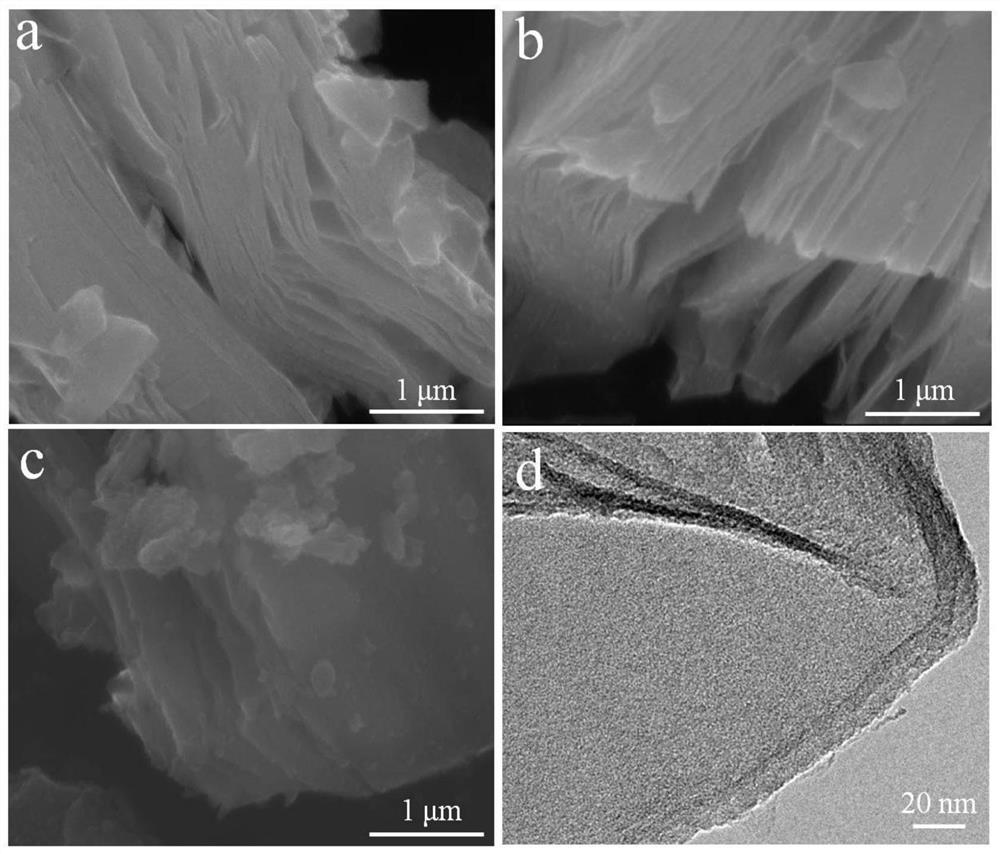

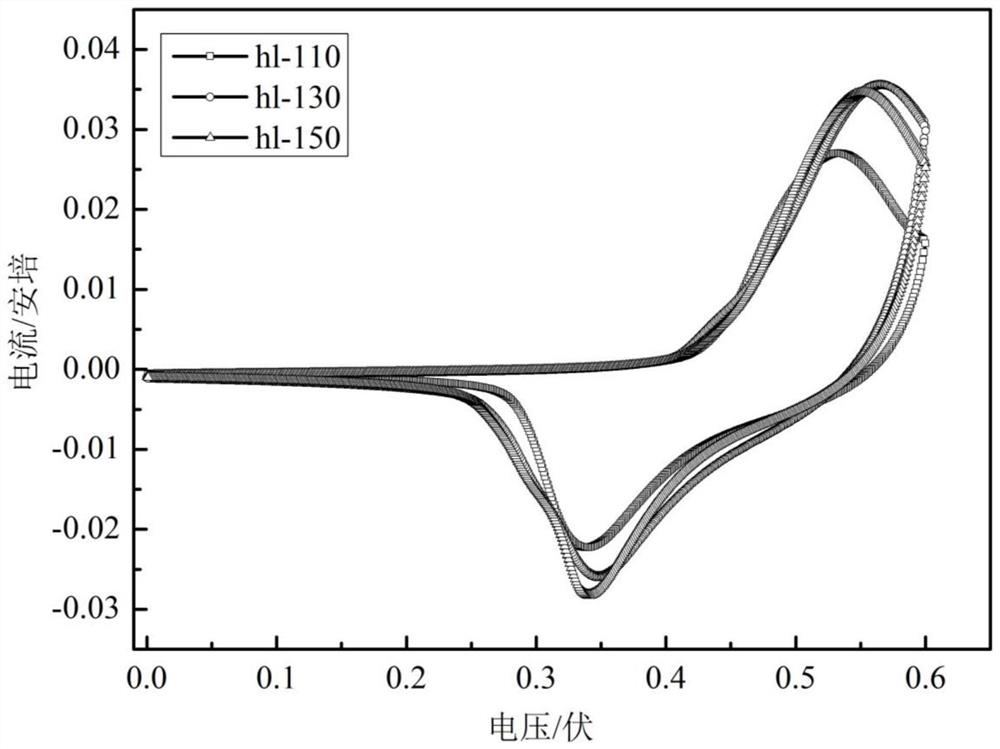

Embodiment 1

[0054] Configure 0.03mol / L (NH 4 ) 2 TiF 6 solution and 0.09mol / L H 3 BO 3 Solution, magnetically stirred and mixed evenly to make a reaction deposition solution, weighed 0.02g Ti 3 AlC 2 Add the reaction deposition liquid, put the reaction deposition liquid into a 100mL hydrothermal reaction kettle, then put the hydrothermal reaction kettle into an oven to synthesize and react at 110° C. for 3 hours. After the reaction, the obtained suspension was centrifuged, and the lower suspension was removed, washed alternately with deionized water and ethanol until neutral, and then the obtained solid was vacuum-dried at 80°C for 24 hours to obtain Ti 3 C 2 -MXene / TiO 2 Powder material.

Embodiment 2

[0056] Configure 0.03mol / L (NH 4 ) 2 TiF 6 solution and 0.09mol / L H 3 BO 3 Solution, magnetically stirred and mixed evenly to make a reaction deposition solution, weighed 0.02g Ti 3 AlC 2 Add the reaction deposition liquid, put the reaction deposition liquid into a 100mL hydrothermal reaction kettle, then put the hydrothermal reaction kettle into an oven to synthesize and react at 130° C. for 3 hours. After the reaction, the obtained suspension was centrifuged, and the lower suspension was removed, washed alternately with deionized water and ethanol until neutral, and then the obtained solid was vacuum-dried at 80°C for 24 hours to obtain Ti 3 C 2 -MXene / TiO 2 Powder material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com