Industrial volatile organic waste gas treatment system

A volatile organic waste gas treatment technology, applied in gas treatment, combustion methods, lighting and heating equipment, etc., can solve the problems of insufficient combustion reaction, direct discharge, and escape, so as to improve the efficiency of odor treatment and increase wind resistance , The effect of accelerating the replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

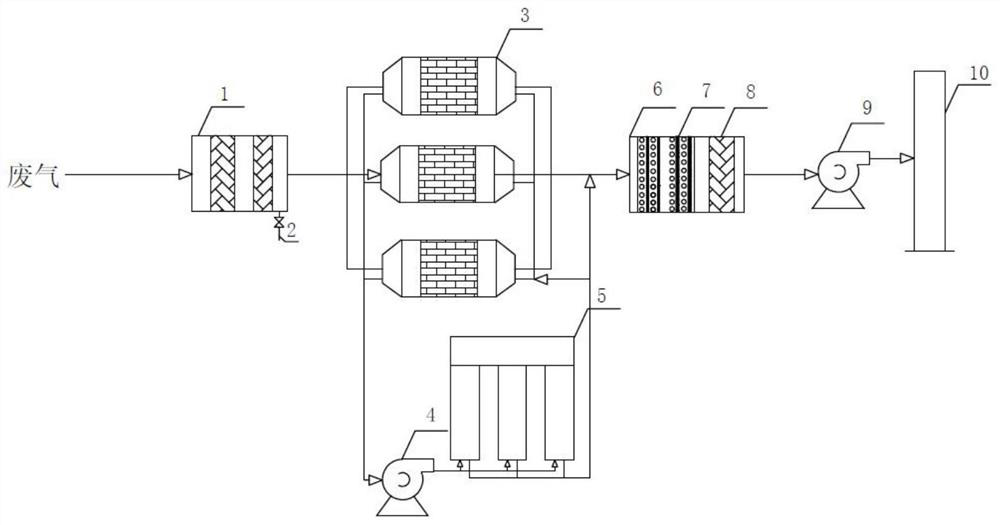

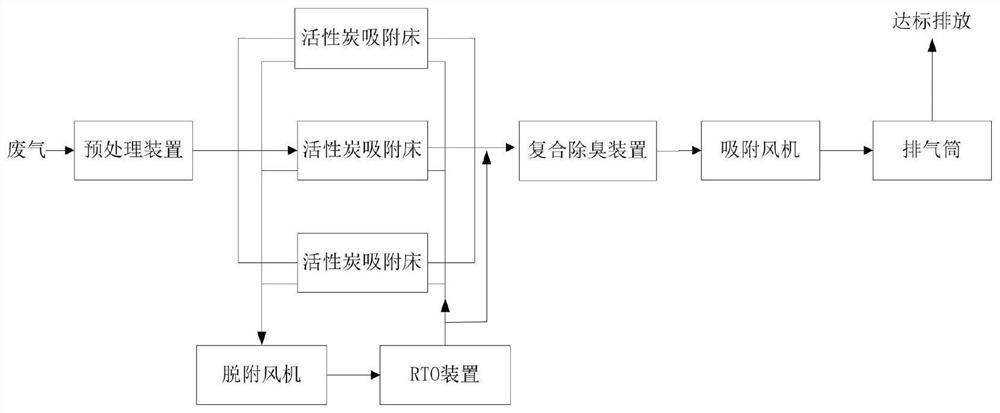

Method used

Image

Examples

Embodiment 1

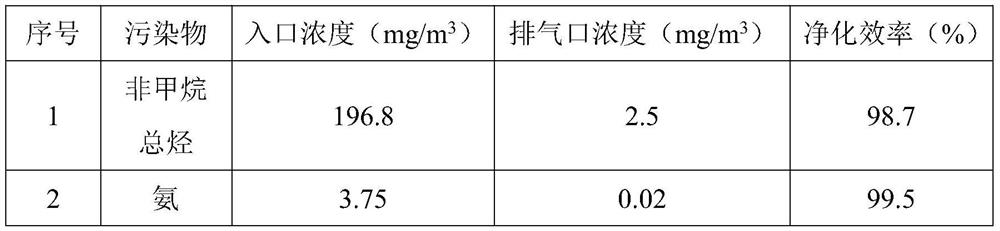

[0039] (1) A chemical company produces drag reducers, and the polymerization workshop produces a certain concentration of VOCs. The main components are olefins, octanol, ether and ammonia, and the concentration is 200mg / m 3 , the wind volume is 60000m 3 / h, using the treatment system of the present application to process VOCs, the exhaust gas is concentrated 20 times, and the treatment efficiency is shown in Table 1 below.

[0040] Table 1

[0041]

[0042] (2) The waste gas produced by a fine chemical company is mainly acetone, with a treatment capacity of 13000m 3 / h, the concentration of acetone is 1100mg / m 3 , the emission concentration is required to be 32mg / m 3 , has high requirements for treatment efficiency, adopts the treatment system of this patent, concentrates 15-20 times, and after treatment, its emission concentration is as shown in Table 2.

[0043] Table 2

[0044] serial number Pollutants Inlet concentration (mg / m 3 )

Exhaust outlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com