A kind of rubber composition and a kind of vulcanized rubber and its preparation method and application

A rubber composition and the technology of the composition are applied in the directions of transportation and packaging, optimization of rolling resistance, special tires, etc., and can solve the problem that the high strength of tire sidewall rubber, the large size of lignin aggregates and the unsatisfactory reinforcement effect cannot be fully satisfied. and other problems, to achieve the effect of good dynamic flexibility, high strength and particle size reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

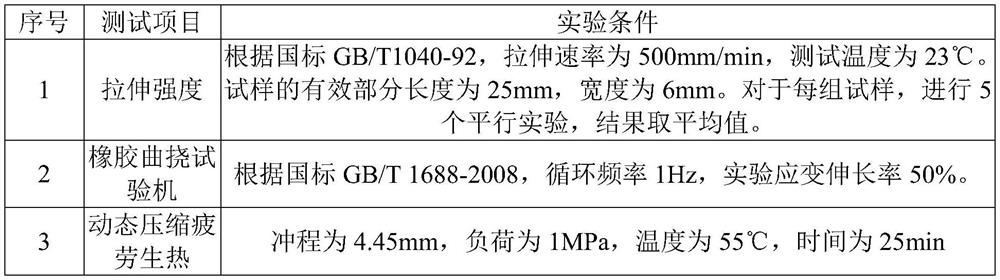

Image

Examples

preparation example Construction

[0050] The following provides some preferred specific embodiments for the method for preparing vulcanized rubber provided by the present invention.

[0051] Preferably, the polymer containing maleic anhydride structural unit and diene structural unit is selected from at least one of maleic anhydride-grafted polybutadiene polymer and maleic anhydride-grafted polyisoprene polymer.

[0052] In the rubber matrix, relative to 100 parts by weight of the rubber matrix, preferably the content of the natural rubber is 35-65 parts by weight, and preferably the content of the butadiene rubber is 35-65 parts by weight.

[0053] Preferably the rubber matrix is a mixture of butadiene rubber and natural rubber.

[0054] Preferably the natural rubber is SMR-20.

[0055] Preferably, the cis-structure content in the cis-butadiene rubber is 95-99% by weight.

[0056] According to a preferred embodiment, with respect to 100 parts by weight of the rubber matrix, the amount of the interface mod...

Embodiment 1

[0096] Rubber composition formula: 35 parts by weight of natural rubber, 65 parts by weight of butadiene rubber, 3 parts by weight of maleic anhydride grafted polybutadiene (interface modifier), 20 parts by weight of lignin, polyethylene glycol (plasticized dispersant) 2 parts by weight, carbon black N550 20 parts by weight, carbon black N330 30 parts by weight, TDAE (softener) 3 parts by weight, zinc oxide (activator) 4 parts by weight, stearic acid (activator) 1 part by weight , 0.5 parts by weight of sulfur (vulcanizing agent), 5 parts by weight of TBBS (accelerator), and 2 parts by weight of anti-aging agent 4020 (anti-aging agent).

[0097] Preparation process of vulcanized rubber:

[0098] (1) The first mixing of the rubber matrix and the interface modifier is carried out to obtain a master batch; specifically, natural rubber and cis-butadiene rubber are added to the internal mixer, and the setting speed is 77 rpm, and the initial mixing temperature is 70 ° C , the raw ...

Embodiment 2

[0105] Rubber composition formula: 65 parts by weight of natural rubber, 35 parts by weight of cis-butadiene rubber, 15 parts by weight of maleic anhydride grafted polybutadiene (interface modifier), 50 parts by weight of lignin, PEO-PPO-PEO block 8 parts by weight of copolymer (plasticizing dispersant), 30 parts by weight of carbon black N550, 10 parts by weight of TDAE (softening agent), 4 parts by weight of zinc oxide (activator), 3 parts by weight of stearic acid (activator), sulfur (vulcanizing agent) 4 weight part, accelerator D (accelerator) 1 weight part, antioxidant 4020 (anti-aging agent) 0.5 weight part.

[0106] Preparation process of vulcanized rubber:

[0107] (1) The first mixing of the rubber matrix and the interface modifier is carried out to obtain a master batch; specifically, natural rubber and cis-butadiene rubber are added to the internal mixer, and the setting speed is 77 rpm, and the initial mixing temperature is 70 ° C , the raw rubber mastication tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com