Polyolefin high-concentration plasticizer master batch, and preparation method and application thereof

A polyolefin and plasticizer technology, which is applied in the field of polyolefin high-concentration plasticizer masterbatch and its preparation, can solve the problem that the material cannot achieve the effect of plasticization, the plasticizer is difficult to disperse uniformly, and the antifogging agent is difficult to Uniform dispersion and other problems, to achieve the effect of low cost, excellent physical and mechanical properties, and solving processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

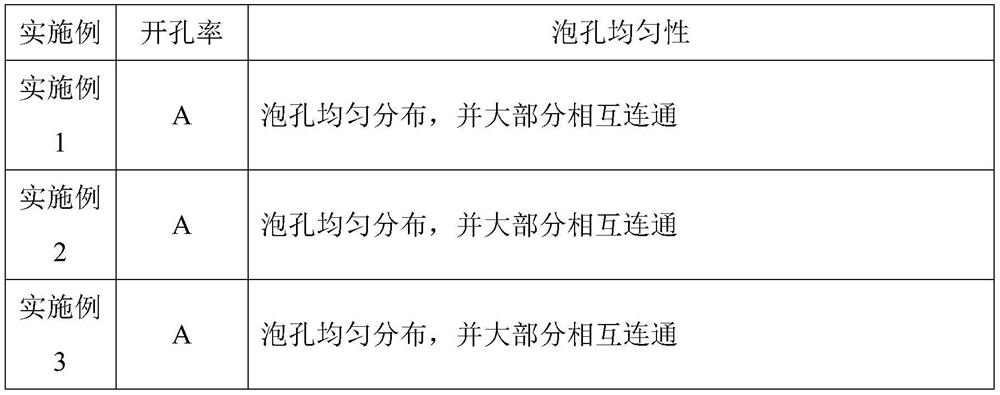

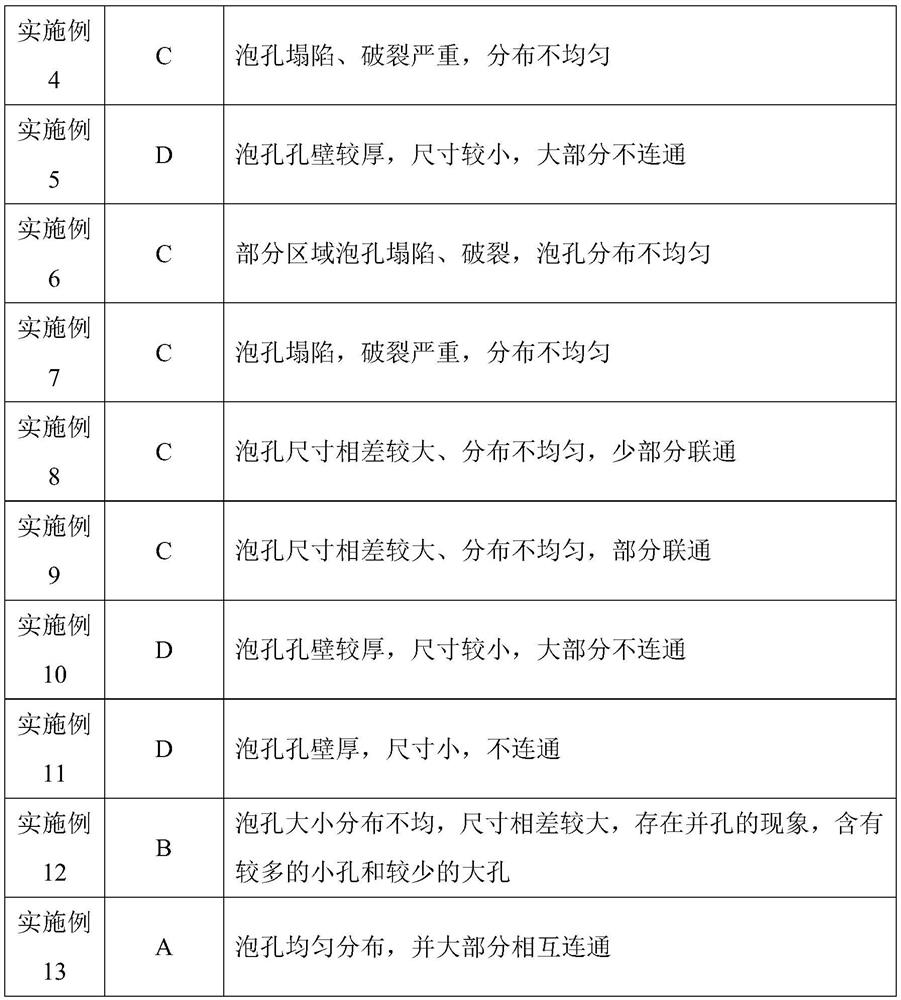

Examples

preparation example Construction

[0091] In the present invention, the preparation method of the foamed polyolefin carrier at least includes the following steps:

[0092] (1) Add polyolefin, modifier, nucleating agent, antioxidant and lubricant to the extruder after mixing;

[0093] (2) inject blowing agent with the pressure of 10-20MPa in the compression section of extruder, extrude through the die head of extruder after mixing uniformly, obtain foamed polyolefin carrier; The die head of described extruder is Circular hole die with a hole diameter of 0.5-2mm.

[0094] In a preferred embodiment, the number of the circular hole dies is 2-30.

[0095] In a preferred embodiment, the extruder is sealed from the feeding port to the die head, and the compressive strength of the barrel of the extruder is ≥35 MPa.

[0096] The foaming agent in the present invention is injected at a certain pressure in the compression section of the extruder, which can ensure the stability of the system pressure and prevent the foami...

Embodiment 1

[0107] Embodiment 1 provides a kind of polyolefin high-concentration plasticizer masterbatch, the preparation raw material of described plasticizer masterbatch comprises expanded polyolefin carrier and plasticizer; Liquid hydrocarbons with a measured weight average molecular weight of 500-8000.

[0108] The liquid hydrocarbons were purchased from ExxonMobil Chemical, model Elevast TM C 30, the weight average molecular weight measured by gel permeation chromatography is 2195.

[0109] The raw materials for the preparation of the foamed polyolefin carrier include a polyolefin carrier composition and a foaming agent; the polyolefin carrier composition, by weight percentage, includes: polyolefin 85%, modifier 10%, nucleating agent 4% agent, 0.5% antioxidant, 0.5% lubricant; the melt flow rate of the polypropylene is 8g / 10min, selected from Sinopec, model F800E; the modifier is styrene-butadiene- Styrene block copolymer, the content of styrene is 25-35wt%, the melt flow rate is n...

Embodiment 2

[0117] Embodiment 2 provides a kind of polyolefin high-concentration plasticizer masterbatch, the preparation raw material of described plasticizer masterbatch comprises expanded polyolefin carrier and plasticizer; Liquid hydrocarbons with a measured weight average molecular weight of 500-8000.

[0118] The liquid hydrocarbons were purchased from ExxonMobil Chemical, model Elevast TM A80, the weight average molecular weight measured by gel permeation chromatography is 670.

[0119] The raw materials for the preparation of the foamed polyolefin carrier include a polyolefin carrier composition and a foaming agent; the polyolefin carrier composition, by weight percentage, includes: 80% polyolefin, 15% modifier, nucleating agent 3% agent, 1% antioxidant, 1% lubricant; the melt flow rate of the polypropylene is 8g / 10min, selected from Sinopec, model F800E; the modifier is styrene-butadiene- Styrene block copolymer, the content of styrene is 25-35wt%, the melt flow rate is not mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com