Ultra-thin fireproof coating for steel structure and application of ultra-thin fireproof coating

A fire retardant coating, ultra-thin technology, applied in fire retardant coatings, anti-corrosion coatings, fire protection and other directions, can solve problems such as hidden safety hazards, poor appearance, fire retardant coating on platform canopy columns, etc. number of applications, or the effect of prolonged protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

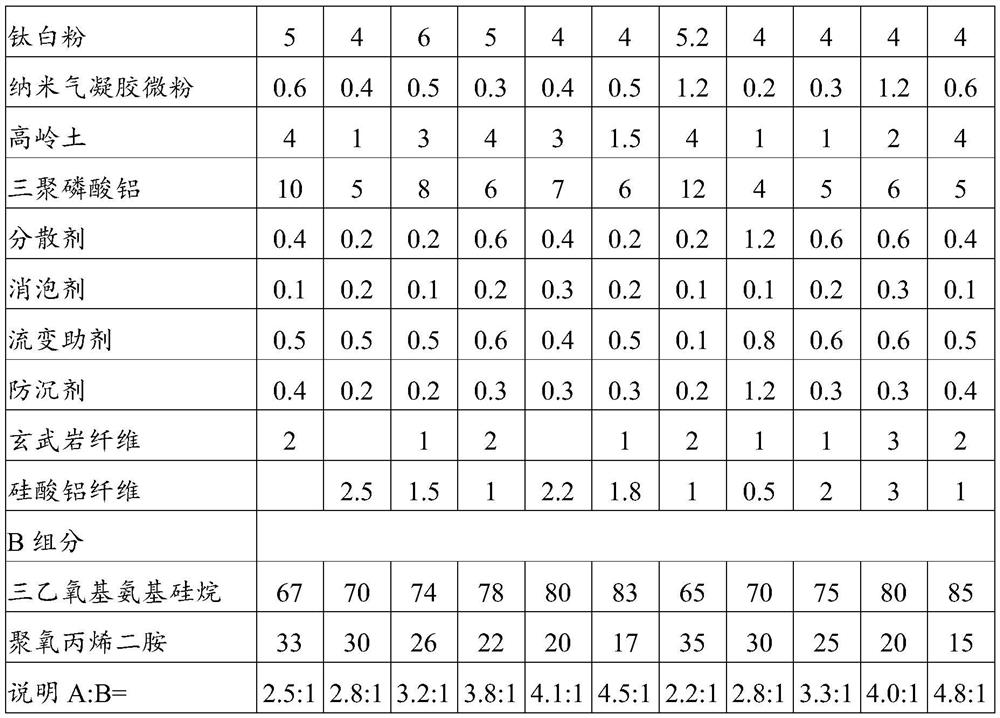

[0042] The ultra-thin fireproof coating for steel structure of the present embodiment comprises A component and B component, and the weight ratio of A component and B component is 2.5:1, and wherein A component is made up of the composition of following parts by weight:

[0043] Silicone epoxy hybrid resin ( EF) 30 parts, liquid petroleum resin (C5) 6 parts, flame retardant (aluminum phenyl hypophosphite) 6 parts, carbon forming agent (pentaerythritol) 10 parts, carbon forming catalyst (ammonium polyphosphate) 10 parts, foaming agent (melamine) 9 parts, reactive diluent (AGE reactive diluent) 6 parts, rust inhibitor (APW-I aluminum tripolyphosphate) 10 parts, filler (R-902 titanium dioxide 5 parts, KPore-G200 nano airgel 0.6 parts of fine powder, 4 parts of 1250 mesh 5S calcined kaolin) 9.6 parts, additives (0.4 parts of Disponer 9250 wetting and dispersing agent, 0.1 part of BYK-085 defoamer, 0.5 parts of Deurheo202P rheology additive, 0.4 parts of S-8021 anti-settling agent...

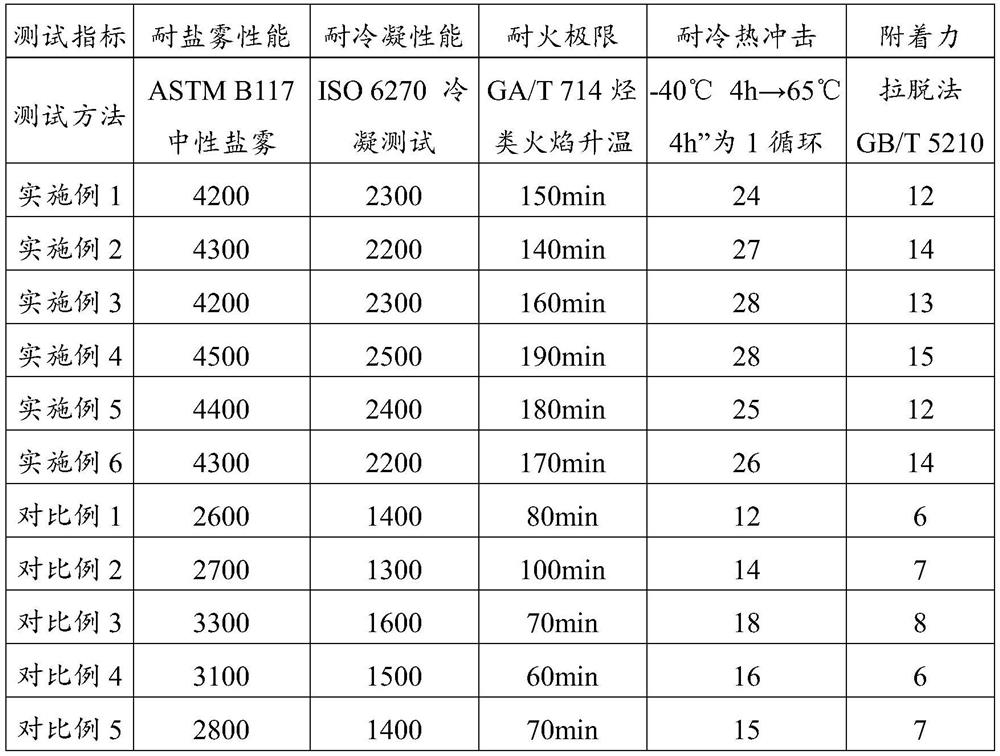

Embodiment 2 to 6 and comparative example 1 to 5

[0055] Examples 2 to 6 and Comparative Examples 1 to 5 were all prepared according to the preparation method in Example 1, and the specific raw material composition ratios are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com