Adhesive sticker cleaning agent and preparation method thereof

A glue cleaning agent and co-solvent technology, applied in the field of cleaning agents, can solve the problems of large pollution, high cost, strong toxicity, etc., and achieve the effects of reducing production costs, improving the use effect, and increasing the volatilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a self-adhesive cleaning agent, comprising the following composition in mass fractions: 50 parts of D-limonene, 25 parts of terpene, 10 parts of hydrated magnesium aluminum silicate, 15 parts of glycerin acetal, anionic surfactant 5 parts, 5 parts of nonionic surfactant, 5 parts of co-solvent, 2 parts of penetrant, 2 parts of pH regulator, 35 parts of water.

[0023] Among them, the median particle size of hydrated magnesium aluminum silicate is 2 μm, the glycerol acetal is glycerol formal, the anionic surfactant is sodium lauryl alcohol polyoxyethylene ether sulfate, and the nonionic surfactant is dodecyl alcohol polyoxyethylene ether sulfate. Alkyl alcohol polyoxyethylene ether, cosolvent is dipropylene glycol, penetrating agent is fatty alcohol polyoxyethylene ether, and pH regulator is triethanolamine.

[0024] The preparation method of this self-adhesive cleaning agent is:

[0025] S1. Mix D-limonene, terpene and co-solvent, stir evenly, a...

Embodiment 2~6

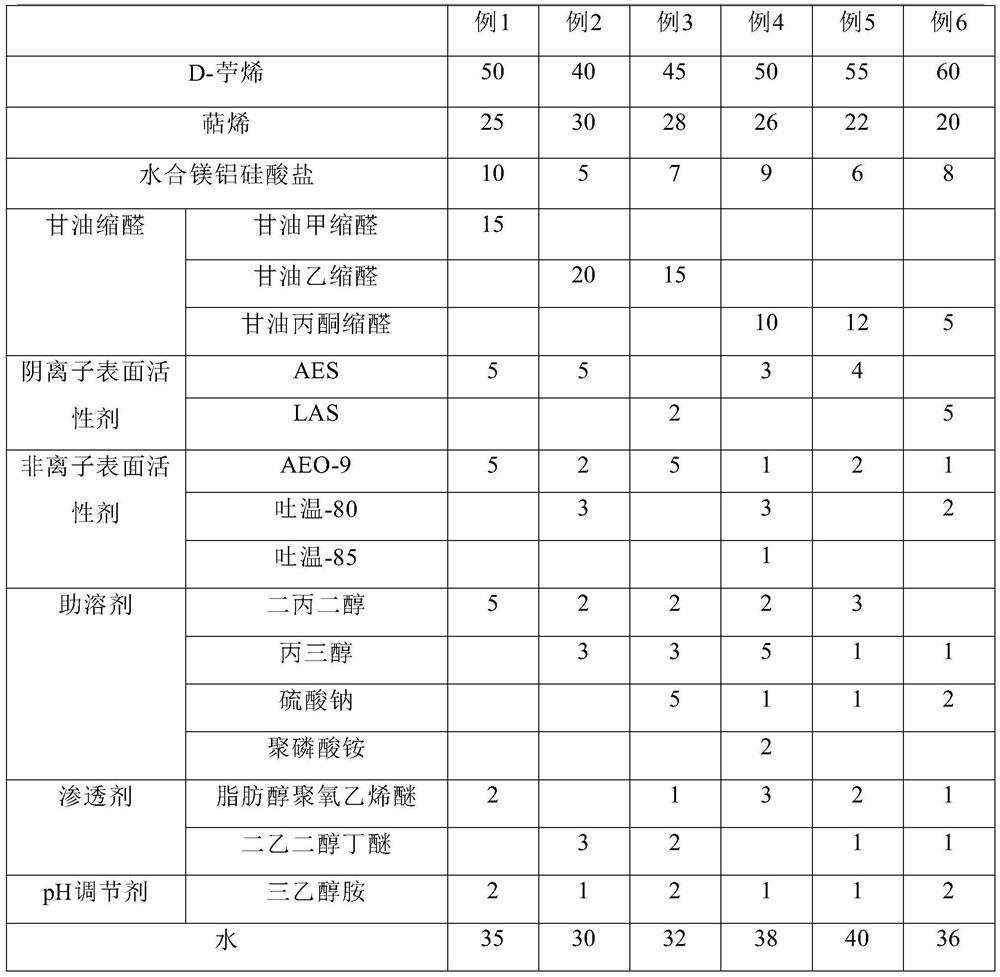

[0028] Embodiment 2~6 preparation method is identical with embodiment 1. See Table 1 for the specific formulations of the self-adhesive cleaning agents of Examples 1-6.

[0029] Table 1

[0030]

[0031]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com