Multi-effect rectification system and method for N-methyl pyrrolidone

A technology of methylpyrrolidone and multi-effect rectification, which is applied in the field of multi-effect rectification systems of N-methylpyrrolidone, can solve the problems of unsatisfactory refining effect and high energy consumption, achieves improved energy saving, improved rectification efficiency, and achieved The effect of thermal coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

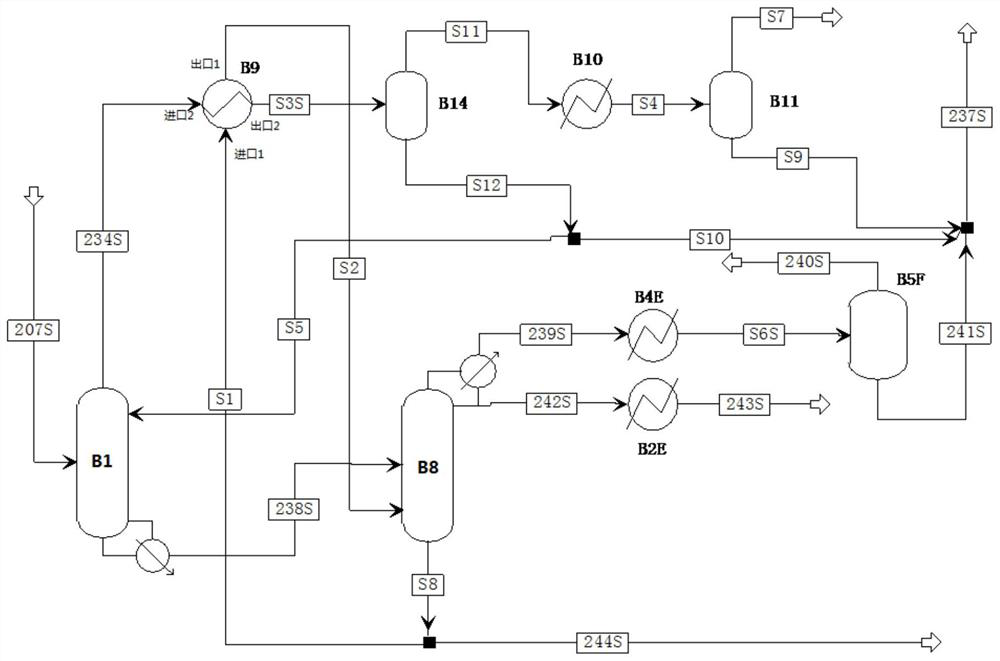

[0066] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

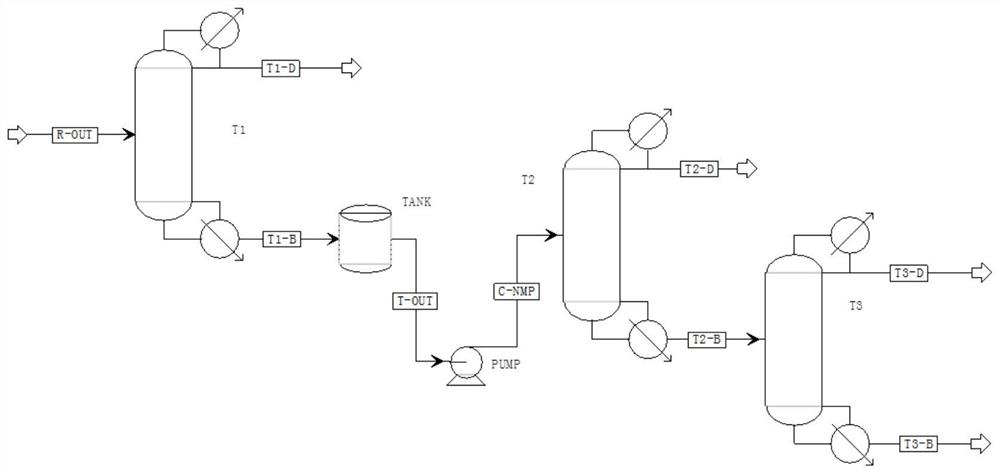

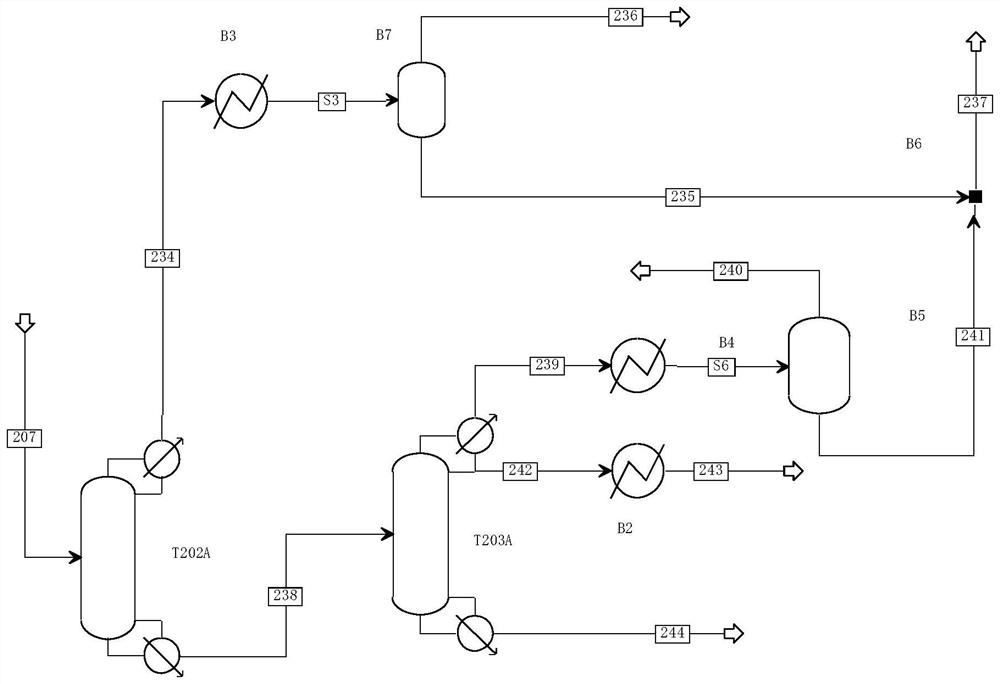

[0067] Such as figure 1 Shown, a kind of NMP multi-effect rectification system, it comprises following device:

[0068] Negative pressure dehydration tower B1, negative pressure dehydration tower tank reboiler; NMP rectification tower B8, NMP rectification tower top condenser; and inter-effect heat exchanger B9, with material inlets 1 and 2 and material outlet 1 and 2; gas-liquid separation devices B14 and B11 and condenser B10; gas-liquid separation device B5F; condenser B2E and condenser B4E.

[0069] The above devices are connected as follows:

[0070] The material outlet of the bottom of the negative pressure dehydration tower B1 is connected to the material inlet of the middle part of the NMP rectification tower B8 through the reboiler of the bottom of the negative pressure dehydration tower B1, and is used to send the material stream 238...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat load | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com