Preparation method of alkali-resistant composite nanofiltration membrane

A composite membrane and alkali-resistant technology, which is applied in the field of membrane separation, can solve problems such as difficulty in stabilization, and achieve the effect of strong charge effect, simple preparation process, and stable removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

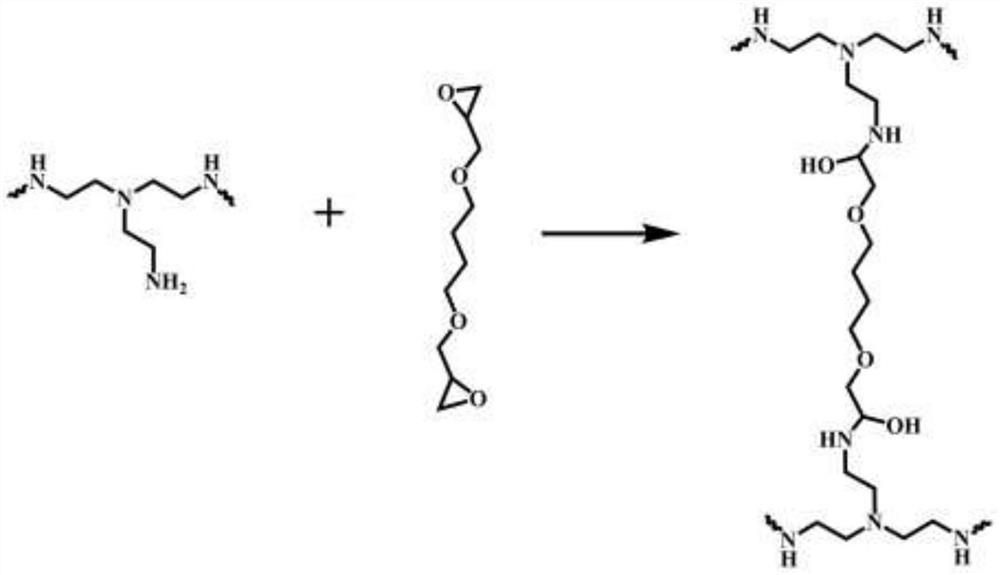

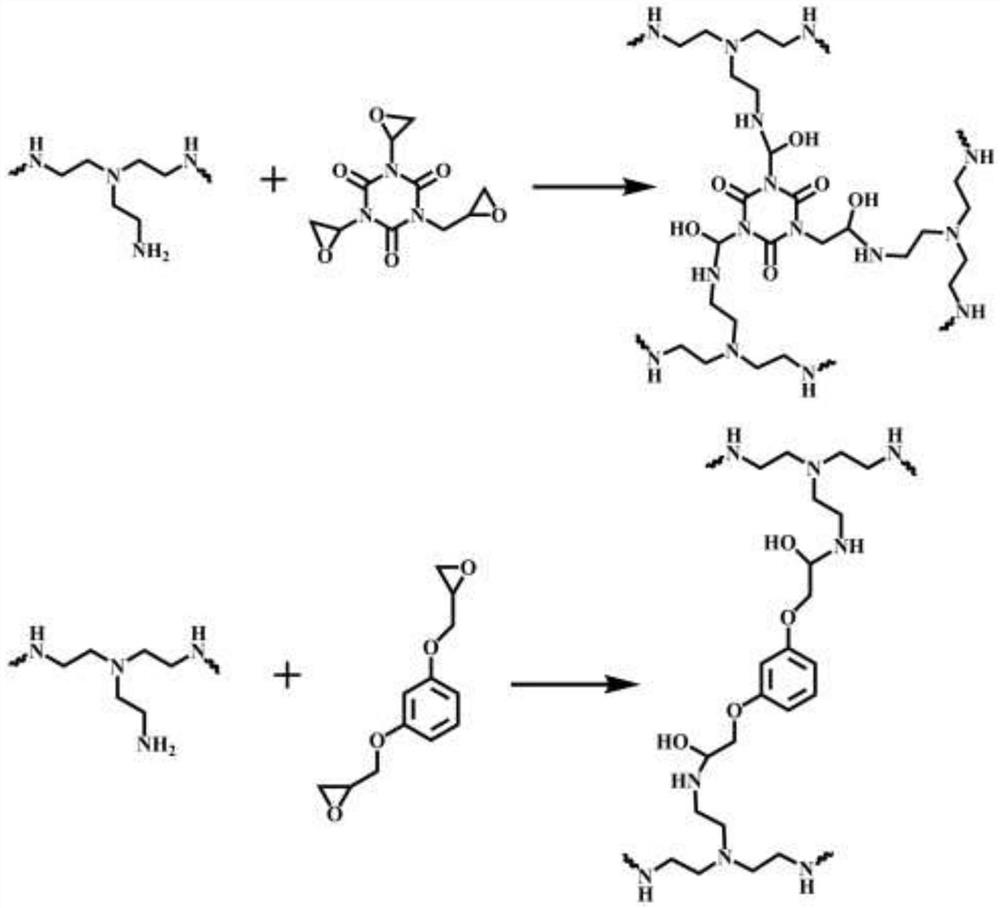

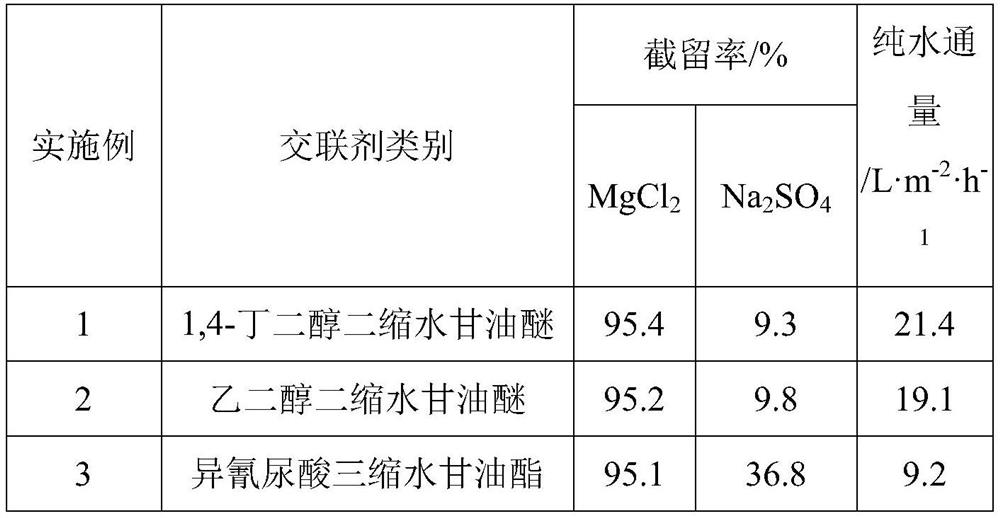

[0026] A crosslinking agent solution with a mass volume concentration (g / 100 ml) of 0.1% was prepared, and the solution contained a sodium dodecylsulfonate surfactant with a mass volume concentration (g / 100 ml) of 0.15%. 1,4-butanediol diglycidyl ether, ethylene glycol diglycidyl ether, and triglycidyl isocyanurate are selected as the crosslinking agent respectively. The cross-linking agent solution was coated on the surface of a polyethersulfone ultrafiltration membrane with a molecular weight cut-off of 30,000 Daltons, and after standing for 5 minutes, it was placed in a blast drying oven at 30°C, and taken out after 10 minutes. A 0.6% polyethyleneimine aqueous solution with a mass volume concentration (g / 100 ml) was coated on the surface of the membrane, and after standing for 2 minutes, heat treatment was performed in an air-blast drying oven at 80° C. for 10 minutes. Membrane performance was tested after washing with deionized water and soaking for 24 hours.

[0027] The...

Embodiment 4-9

[0030] As in the foregoing examples, the surface of the polyethersulfone ultrafiltration membrane is coated with a polyethersulfone ultrafiltration membrane containing mass volume concentration (g / 100 ml) of 0.15% sodium dodecylsulfonate and 0.1% 1,4-butanediol diglycidyl ether. For the joint agent solution, remove the excess solution and dry it in an oven at 30-40°C for 10 minutes. Coat the surface of the film with a polyethyleneimine aqueous solution with a mass volume concentration (g / 100 ml) of 0.2% to 1.2% and a molecular weight of 70,000 Daltons. After standing for 2 minutes, remove the excess solution and place it in an air-dried oven at 80°C. After 10 minutes in the box, remove and store in deionized water.

[0031] The desalination and water permeation performances were tested under 500ppm salt solution, operating temperature 25°C, and operating pressure 0.2MPa.

[0032]

Embodiment 10-15

[0034] Like above-mentioned embodiment, the cross-linking agent solution that contains mass volume concentration (gram / 100 milliliter) 0.15% sodium dodecyl sulfonate and 0.1% triglycidyl isocyanurate is infiltrated on the polyethersulfone ultrafiltration membrane surface, in Dry in an oven at 30°C for 10 minutes. The film surface is coated with a polyethyleneimine aqueous solution with a mass volume concentration (g / 100 ml) of 1.2% molecular weight and a molecular weight of 70,000 Daltons. After standing for 2 minutes, the excess solution is removed and placed in a blast drying oven at 80°C for 10 Remove after 1 min and store in deionized water.

[0035] The test liquid is deionized water, sodium hydroxide is used to adjust the pH value of the feed liquid, the operating temperature is 25°C, and the operating pressure is 0.2 MPa to test the membrane performance.

[0036]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com