Sampler for brominated flame retardants in indoor air and sampling and measuring method thereof

A brominated flame retardant, indoor air technology, applied in the field of analysis and detection, can solve problems such as pollution, target compound loss background, cumbersome process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

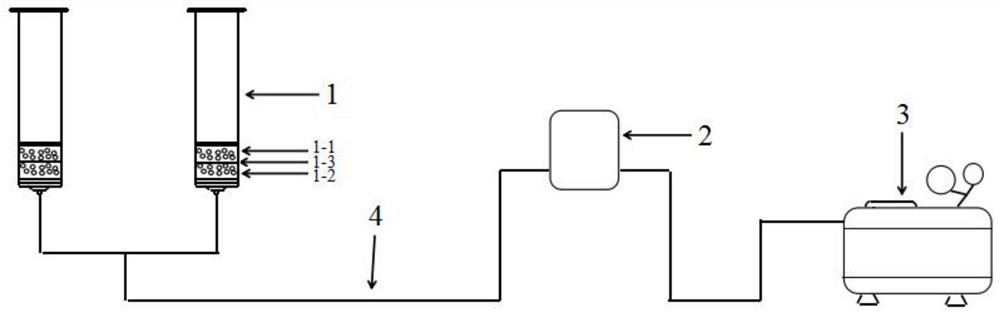

[0062] (1) Sample collection

[0063] The sampler for brominated flame retardants is composed of a solid-phase extraction column, a flow meter (range 0-25L / min), and a diaphragm vacuum pump (maximum pumping rate 20L / min) sequentially connected through a silicone tube. The structure is as follows: figure 1 shown. Among them, there are two solid-phase extraction columns connected in parallel. Each column has an inner diameter of 12.8mm, an outer diameter of 14.7mm, and a height of 68mm; each column is filled with 250mg CNWBOND HC-C18 filler and 250mg CNWBOND NH 2 Filler (filler particle size is 40 ~ 63μm, average pore size Ion exchange capacity 1.6meq / g), the two fillers are not mixed with each other, separated by glass fiber sieve plate, CNWBOND HC-C18 filler is on the upper layer, CNWBOND NH 2 The padding is on the lower layer.

[0064] Air samples were collected in 3 different rooms of the same hotel. Before sample collection, activate the solid-phase extraction column w...

Embodiment 2

[0076] (1) Sample collection

[0077] Sampler is the same as embodiment 1.

[0078] Air sample collection was performed in 4 different dormitories in the same dormitory building. Before sample collection, activate the solid-phase extraction column with 4mL methanol, 4mL ethyl acetate, 4mL methylene chloride, and 4mL n-hexane in sequence, wrap it in aluminum foil and seal it in a polypropylene bag for storage, and then carry it to the sampling site. The sampling device is placed at a height of 1.2m from the ground, the sampling rate is about 4.0L / min, and the sample collection time is 8h. After the sampling was completed, the solid-phase extraction column was still wrapped in aluminum foil, sealed in a polypropylene bag, transported back to the laboratory as soon as possible, and stored in a -20°C refrigerator until processing.

[0079] (2) Sample processing

[0080] Before the elution of the solid-phase extraction cartridge, 5 ng of polybrominated diphenyl ethers (PBDEs) in...

Embodiment 3

[0091] (1) Sample collection

[0092] Sampler is the same as embodiment 1.

[0093] Air sampling was performed in 3 different rooms within the same household. Before sample collection, activate the solid-phase extraction column with 4mL methanol, 4mL ethyl acetate, 4mL methylene chloride, and 4mL n-hexane in sequence, wrap it in aluminum foil and seal it in a polypropylene bag for storage, and then carry it to the sampling site. The sampling device is placed at a height of 1.2m from the ground, the sampling rate is about 4.0L / min, and the sample collection time is 8h. After the sampling was completed, the solid-phase extraction column was still wrapped in aluminum foil, sealed in a polypropylene bag, transported back to the laboratory as soon as possible, and stored in a -20°C refrigerator until processing.

[0094] (2) Sample processing

[0095] Before the elution of the solid-phase extraction cartridge, 5 ng of polybrominated diphenyl ethers (PBDEs) internal standard and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com