Reactive ultrasonic rectification and purification method for HF electronic gas

An electronic gas, purification method technology, applied in chemical instruments and methods, fractionation, compounds of elements of Group 4/14 of the periodic table, etc. Efficient water removal and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

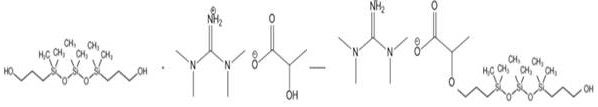

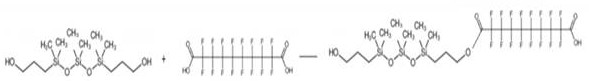

Method used

Image

Examples

Embodiment 1

[0027] A reactive ultrasonic distillation purification method for HF electron gas, the operation steps are:

[0028] Add 50Kg of moisture reactant to 1000Kg of liquefied HF, stir evenly in the mixing tank, and then pump the mixed liquid into the middle of the rectification tower for rectification. The top of the rectification tower is connected to the condenser, and the bottom of the tower is Connect the reboiler, the hydrogen fluoride gas generated by the heating of the reboiler is condensed through the condenser, the reflux ratio is controlled to be between 1.2, the theoretical plate number of the rectification tower is 10, the rectification pressure is 5bar, and the temperature at the top of the tower is minus 20 °C, the temperature at the bottom of the tower is -10 °C; the liquefied HF after rectification is filtered through a filter membrane; the rectification tower is in an ultrasonic field, its ultrasonic frequency is 30KHz, and its ultrasonic power is 10W / cm2; it is cha...

Embodiment 2

[0038] A reactive ultrasonic distillation purification method for HF electron gas, the operation steps are:

[0039]Add 50Kg of moisture reactant to 1000Kg of liquefied HF, stir evenly in the mixing tank, and then pump the mixed liquid into the middle of the rectification tower for rectification. The top of the rectification tower is connected to the condenser, and the bottom of the tower is Connect the reboiler, the hydrogen fluoride gas generated by the heating of the reboiler is condensed through the condenser, the reflux ratio is controlled to be between 1.2, the theoretical plate number of the rectification tower is 10, the rectification pressure is 5bar, and the temperature at the top of the tower is minus 20 °C, the temperature at the bottom of the tower is -10 °C; the liquefied HF after rectification is filtered through a filter membrane; the rectification tower is in an ultrasonic field, its ultrasonic frequency is 30KHz, and its ultrasonic power is 10W / cm2; it is char...

Embodiment 3

[0049] A reactive ultrasonic distillation purification method for HF electron gas, the operation steps are:

[0050] Add 100Kg of moisture reactant to 5000Kg of liquefied HF, stir evenly in the mixing tank, and then pump the mixed liquid into the middle of the rectification tower for rectification. The top of the rectification tower is connected to the condenser, and the bottom of the tower is Connect the reboiler, the hydrogen fluoride gas generated by heating the reboiler is condensed by the condenser, the reflux ratio is controlled to be between 2.5, the theoretical plate number of the rectification column is 24, the rectification pressure is 15bar, and the tower top temperature is minus 40 °C, the temperature at the bottom of the tower is 5 °C; the liquefied HF after rectification is filtered through a filter membrane; the rectification tower is in an ultrasonic field, its ultrasonic frequency is 100KHz, and its ultrasonic power is 40W / cm2; it is characterized in that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com