Aluminum diethyl phosphinate material and preparation method thereof

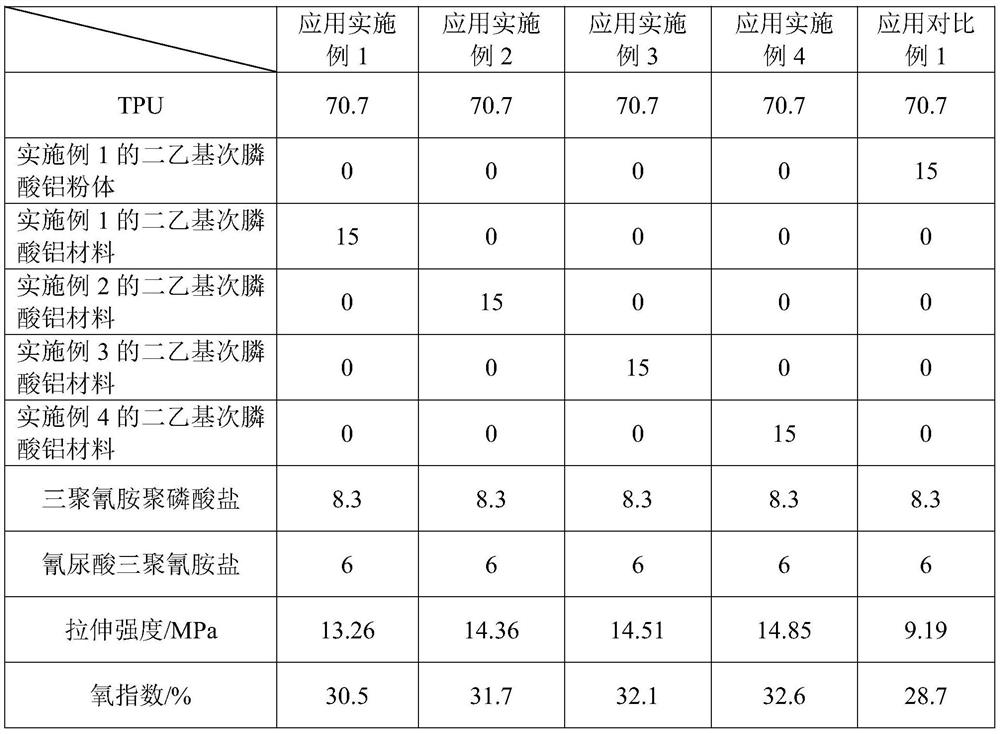

A technology of diethylphosphinic acid and aluminum ethylphosphinate, applied in the field of flame retardant materials, can solve the problems of large dust, poor dispersion effect, and affecting the flame retardant and mechanical properties of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of aluminum diethylphosphinate material provided by the invention comprises:

[0024] S1, providing a mixed acid solution and a suspension containing an aluminum source, wherein the mixed acid solution includes dialkylphosphinic acid and a crystallization aid;

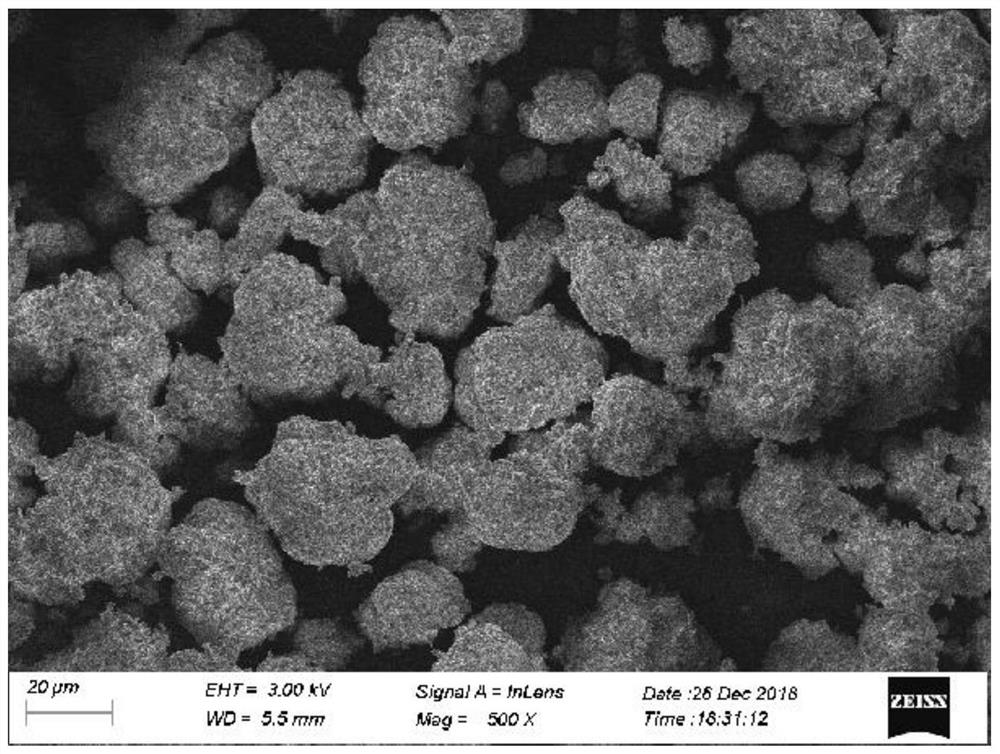

[0025] S2, mixing the mixed acid solution with the suspension, reacting to obtain aluminum diethylphosphinate particles, and stacking a plurality of aluminum diethylphosphinate particles to form a powder with a porous structure, wherein The powder has a D95 particle size distribution of 5 μm-30 μm;

[0026] S3, the powder is placed in a mixer for mixing, the coupling agent is added to the mixer by spraying and mixed with the powder, and the coupling agent is combined with the powder Obtain aluminum diethylphosphinate material, wherein the bulk density of aluminum diethylphosphinate material is 0.45g / cm 3 -0.70g / cm 3 .

[0027] In step S1, the aluminum source includes at least one of al...

Embodiment 1

[0055] Aluminum sulfate is pre-dispersed in water, and the pH value is adjusted to 7.8 by sodium hydroxide to obtain a suspension.

[0056] 90kg of dialkylphosphinic acid and 10kg of crystallization aid di-sec-butylphosphinic acid (bis(1-methylpropyl)phosphinic acid) were mixed to form a mixed acid solution.

[0057] At 50°C and 1 bar, under the condition that the molar ratio of aluminum sulfate to diethylphosphinic acid is 1:3, mix the above mixed acid solution and suspension to react to obtain aluminum diethylphosphinate powder . The aluminum diethylphosphinate powder is formed by stacking a plurality of aluminum diethylphosphinate particles, has a porous structure, the particle diameter D95 is 15.12 μm, and the bulk density of the powder is 0.23 g / cm 3 .

[0058] Weigh 50kg of the above-prepared aluminum diethylphosphinate powder and 0.5kg of titanate coupling agent, and pour the weighed aluminum diethylphosphinate powder into the preheated to 120°C In a high-speed mixer...

Embodiment 2

[0060] The sodium metaaluminate is pre-dispersed in water, and the pH value is adjusted to 4.1 by hydrochloric acid to obtain a suspension.

[0061] The dialkylphosphinic acid of 99.9kg is mixed with the crystallization aid dibutylphosphinic acid of 0.1kg, forms mixed acid solution.

[0062] At 150°C and 25 bar, under the condition that the molar ratio of sodium metaaluminate to diethylphosphinic acid is 1:10, the above mixed acid solution and suspension are mixed to react to obtain aluminum diethylphosphinate Powder. The aluminum diethylphosphinate powder is formed by stacking a plurality of aluminum diethylphosphinate particles, has a porous structure, the particle diameter D95 is 29.21 μm, and the bulk density of the powder is 0.310 g / cm 3 .

[0063] Weigh 50kg of the above-prepared aluminum diethylphosphinate powder and 1.5kg of silane coupling agent, and pour the weighed aluminum diethylphosphinate powder into a high-speed In the mixer, mix at a speed of 400r / min for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com