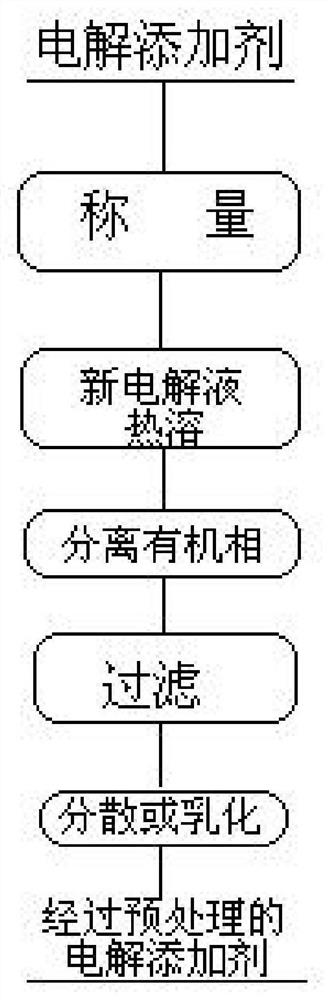

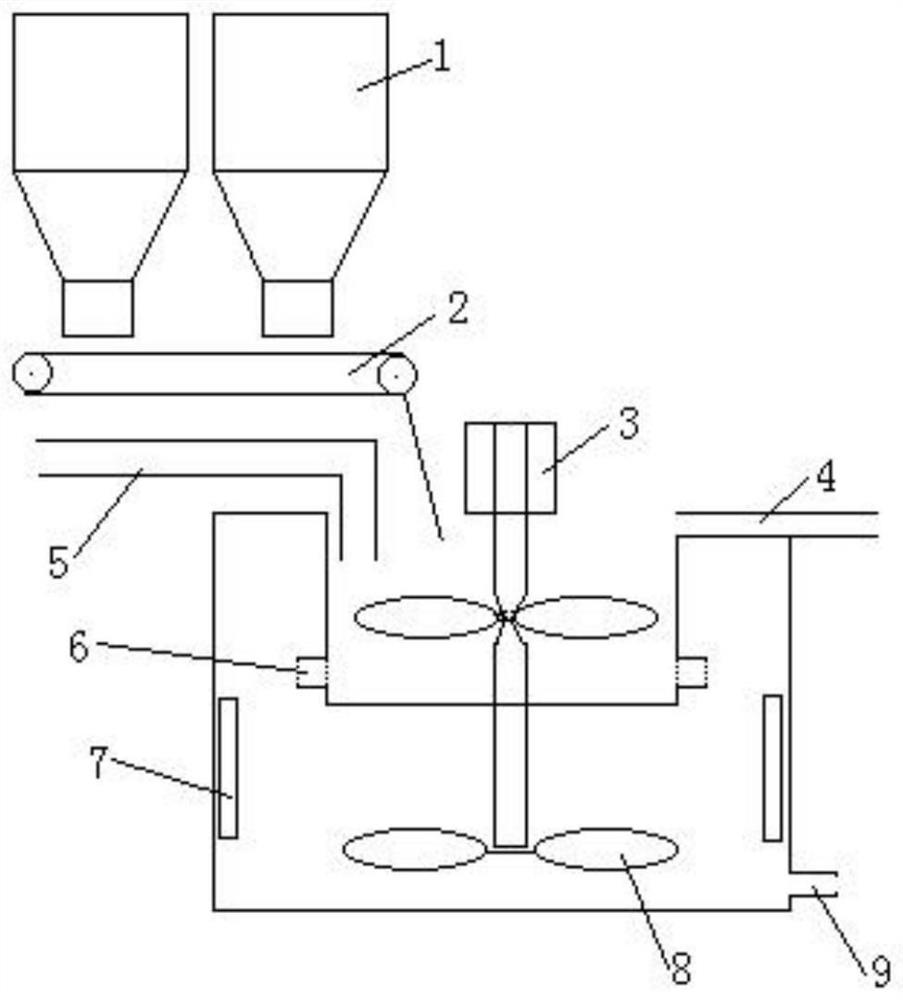

Pretreatment method and device of hydrometallurgy electrolysis additive

A pretreatment device and hydrometallurgy technology, applied in electrolysis components, electrolysis process and other directions, can solve the problems of large amount of additives, new impurities introduced in electrolysis power consumption, poor effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The new liquid and the waste liquid are used together, wherein the acid concentration of the new liquid is 163g / L, and the zinc concentration is 54g / L; the acid concentration of the waste liquid is 168g / L, and the zinc concentration is 50g / L. In the experiment, 20L of 1:1 new and old zinc sulfate solution was used as the electrolyte, a 20cm×15cm lead-silver alloy plate was used as the anode plate, and a 20.5cm×15.5cm rolled aluminum plate was used as the cathode plate, and the current density during electrolysis was controlled at 400A / m 2, the pole distance is 35mm, the cell voltage is 3.1V, and the temperature during electrolysis is controlled at 38°C. During the 24h electrolysis cycle, add EDTA30mg, SrCO 3 1500mg, gelatin 150mg, compare the effects of different addition methods on the current efficiency and cathode quality.

[0041] Zinc electrolysis current efficiency Zn Pb Fe Cd Cu Traditional way to add 89.92% 99.855% 0.026% 0.078% ...

Embodiment 2

[0043] In the experiment, 20L copper sulfate solution was used as the electrolyte, and Cu in the electrolyte 2+ 49g / L, H 2 SO 4 188g / L. During electrolytic refining, a thick copper plate with a size of 20cm×15cm is used as an anode, and a stainless steel plate with a size of 20.5cm×15.5cm is used as a cathode. Control the cathode current density to 300A / m 2 , the pole distance is 45mm, the cell voltage is 0.3V, and the electrolysis temperature is 60°C. During the electrolysis period of 24 hours, 12mg of animal glue, 10mg of thiourea, 10mg of casein, and hydrochloric acid are added to the electrolyte according to the traditional method and the pretreatment method respectively. 0.2ml, to compare the effects of different addition methods on the current efficiency and cathode quality.

[0044] copper electrolysis current efficiency Cu Pb Bi As S Traditional way to add 92.75% 99.92% 0.007% 0.0015% 0.002% 0.005% Added after preprocessing 97....

Embodiment 3

[0046] In the experiment, 20L lead fluorosilicate solution was used as the electrolyte, Pb 2+ Concentration 100g / L, free fluorosilicic acid (H 2 SiF 6 ) 100g / L. During electrolytic refining, crude lead with a size of 20cm×15cm is used as an anode, and a pure lead cathode with a size of 20.5cm×15.5cm is used. Control the cathode current density to 200A / m 2 , the pole distance is 40mm, the cell voltage is 0.4V, and the electrolysis temperature is 40°C. During the 24h electrolysis cycle, add 180mg of bone glue, 180mg of sodium lignosulfonate, and β-naphthol to the electrolyte according to the traditional method and pretreatment method respectively. 5mg, to compare the effects of different addition methods on the current efficiency and cathode quality.

[0047] lead electrolysis current efficiency Pb Ag Cu As Bi sn Traditional way to add 92.75% 99.95% 0.0043% 0.003% 0.0025% 0.0086% 0.005% Added after preprocessing 97.13% 99.99% 0.000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com