A method of making doped amorphous silicon on the back of hbc battery

A technology of amorphous silicon and hydrogenated amorphous silicon, which is applied in the manufacture of circuits, electrical components, and final products, can solve the problems of complex process flow, high production cost, and many process steps, and increase the window and machine cost. Reduction, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

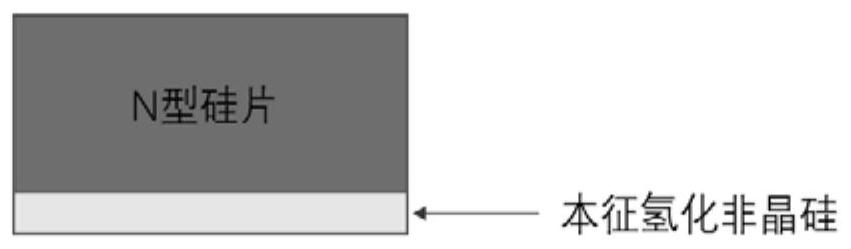

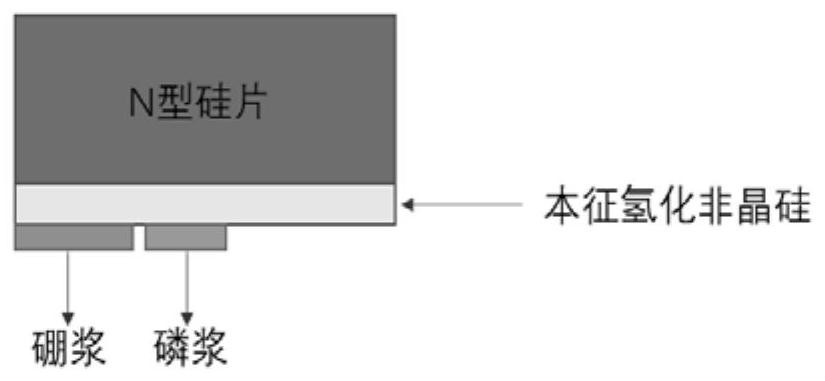

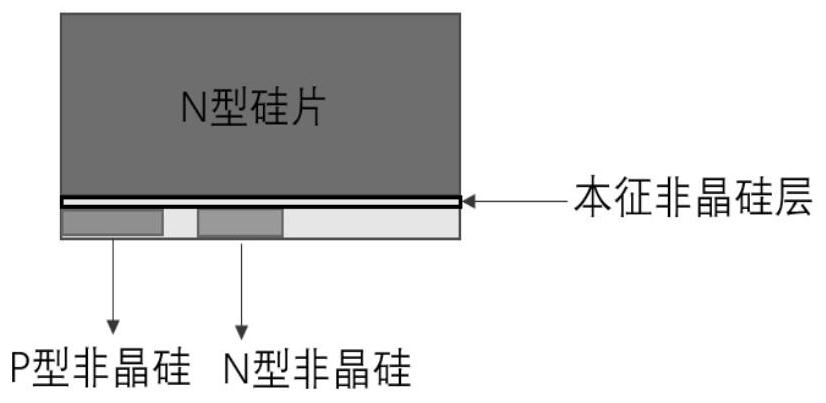

[0036] Such as Figure 1-6 Shown, a kind of method for making HBC cell back doped amorphous silicon, comprises the following steps:

[0037] (1) The intrinsic hydrogenated amorphous silicon layer (i-a-Si: H) is grown by PECVD on the back of the N-type polished wafer, the deposition temperature is 200°C, the deposition power is 50W, the deposition pressure is 200Pa, and hydrogen and silane are introduced. The growth thickness is about 100nm, of which 10nm is used as a passivation layer on the back surface, and the rest is used as a doped amorphous silicon layer.

[0038] (2) Print boron paste on the amorphous silicon layer, the printed pattern is consistent with the screen pattern in the P area of the metallized electrode, and dry at 100° C. for 5 minutes. In some preferred manners, the printing width can be adjusted according to the line width of the screen.

[0039] (3) Phosphorus paste is printed on the amorphous silicon layer, and the printed pattern is consistent with ...

Embodiment 2

[0046] Such as Figure 1-6Shown, a kind of method for making HBC cell back doped amorphous silicon, comprises the following steps:

[0047] (1) An intrinsic hydrogenated amorphous silicon layer (i-a-Si: H) is grown on the back of the N-type polished wafer, with a thickness of about 120nm, of which 10nm is used as a passivation layer on the back surface, and the rest is used as doped amorphous silicon Floor.

[0048] (2) Print boron paste on the amorphous silicon layer, the printed pattern is consistent with the screen pattern in the P area of the metallized electrode, and dry at 100° C. for 5 minutes.

[0049] (3) Phosphorus paste is printed on the amorphous silicon layer, and the printed pattern is consistent with the screen pattern in the N area of the metallized electrode, and dried at 100° C. for 5 minutes.

[0050] (4) Put the printed silicon chip into the laser for laser doping, and obtain the required square resistance of the P area and the N area, wherein, the P ...

Embodiment 3

[0055] Such as Figure 1-6 Shown, a kind of method for making HBC cell back doped amorphous silicon, comprises the following steps:

[0056] (1) An intrinsic hydrogenated amorphous silicon layer (i-a-Si: H) is grown on the back of the N-type polished wafer, with a thickness of about 150nm, of which 15nm is used as a passivation layer on the back surface, and the rest is used as doped amorphous silicon Floor.

[0057] (2) Print boron paste on the amorphous silicon layer, the printed pattern is consistent with the screen pattern in the P area of the metallized electrode, and dry at 100° C. for 5 minutes.

[0058] (3) Phosphorus paste is printed on the amorphous silicon layer, and the printed pattern is consistent with the screen pattern in the N area of the metallized electrode, and dried at 100° C. for 5 minutes.

[0059] (4) Put the printed silicon chip into the laser for laser doping, and obtain the required square resistance of the P area and the N area, wherein, the P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com